How to Use Electrical Lockout Devices and Equipments?

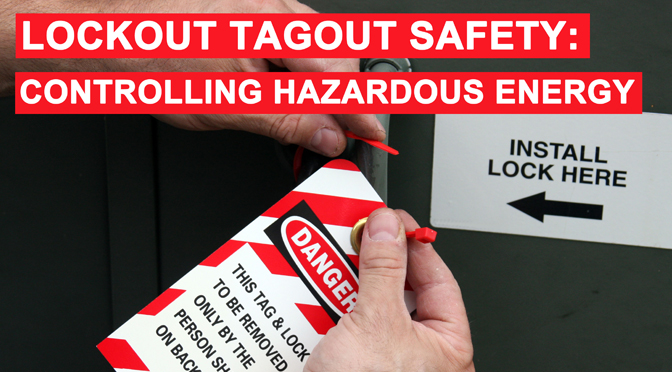

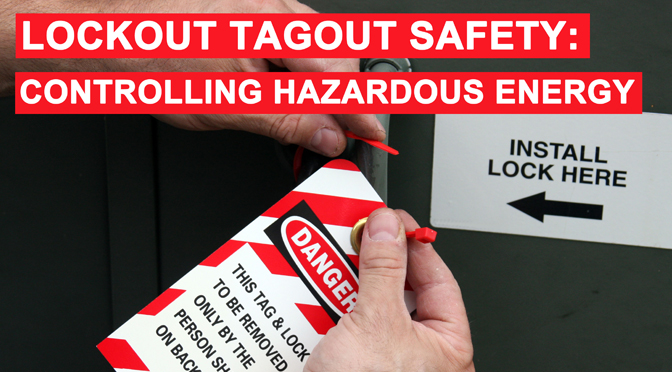

When utilized in industrial high voltage or low voltage applications, electrical lockout devices may help prevent electrical accidents by ensuring that electrical systems are properly shut off. One of the most common methods of preventing accidental or unintentional access to electrical power sources is implementing a Lockout-Tagout technique (LOTO).

Using this secure process, every person working on the same circuit or piece of equipment has a lock that they fasten to a disconnect device before starting their job.

Lockout operations are complete when the disconnect switch or isolation device is free of all locks and lockout devices, indicating that the last worker has granted permission for the line to be re-energized after the lockout operation has been completed.

Procedure to Use the Electrical Lockout Tagout Devices

A normal lockout Tagout method calls for locating all possible power sources. A qualified worker must properly inform on the scope of the operation before they shut down the line or circuit. The following are some of the methods on how to use Electrical Lockout Devices and Equipment.

Locate the process that will follow

Binders or lockout Tagout software may use in your organization. First, locate the steps to use electrical lockout devices necessary for the machine you will be working on and follow them to completion.

According to the manufacturer’s recommendations, this technique should describe the step-by-step approach for shutting down and restarting the equipment. Read More: What Are The Usage Of Electrical Plug Lockouts?

Notify any concerned persons

Any work on the equipment must complete only after all co-workers, contractors, and other parties who may inform of the project’s progress. In addition, if any adjustments need to be made to work procedures, make sure that everyone is informed of these changes.

Find all energy sources

The Lockout Tagout technique you are using should include all of the energy sources that need to be disconnected or isolated. It may even be able to produce images that reveal the specific position of the harmful energy source. Read More: Electrical Panel Lockout Switches With Safety

Turn off the machine

The lockout Tagout method should include a list of the procedures to be taken to do this and specific instructions on how to shut down the equipment. Some devices or equipment need several steps to be completed before they may be shut down. Moreover, Valve Lockout is the major equipment that is used to block harmful and hazardous materials from pipes supplies.

Lockout and tag all energy isolators

Make use of the locks and tags that have been assigned to you. In most cases, this requires permission. If more than one person is engaged in the maintenance or service of the machine or equipment, each individual must connect their lock or tag to the energy isolating device.

From the Loto Kit, using Electrical Lockout Devices and Equipment can improve employee productivity and efficiency. It also prevents issues from arising in the first place, which leads to a safer working environment.

These are the Popular Safety House LOTO Products

>> MCB Lockout

>> Group Lockout Box

>> Scaffold Tag

Keeping the work facility safe: A guide for employers

General industry workers who service and maintain the machineries are exposed to unexpected energization, startup and release of hazardous energy. The work practices can prove to be fatal if proper safety measures aren’t followed. This is where OSHA heavily focuses. OSHA’s standard 1910.147 is all about the control of hazardous energy (lockout/tagout) and requires energy control procedures for all the machines that are prone to dysfunction and could be a source of mechanical/chemical/thermal/hydraulic energy outburst.

Who has the ultimate responsibility to implement lockout safety procedure within a facility? This is perhaps the most-asked question. OSHA requires the employers to take proper steps against unexpected machinery startup and energy outbursts. But simply buying the Lockout Tagout Products is not enough. Most of the firms fall short on enabling effective procedures and fast action by employees. They do not have a set of machine-specific instructions and these instructions are generally not handy to the employees.

Follow the below mentioned steps and ensure a consistent and effective lockout safety program:

– Communication is the key: Communicate to your employees the benefits of an effective lockout program. It is your duty to instill in your employees the value of a safe working environment. Also, produce an easy-to-use set of guidelines that your employees understand.

– Make a complete list of machinery that might require lockout safety procedures. It is also important to keep your equipments in a healthy state with timely maintenance and repairs.

– Identify the energy points and label the isolation devices (valves and breaker panels).

– List and document the hardware that might be needed for to lock out and isolate machinery and equipment. Devices such as padlocks and tags.

– There’s no generic safety procedure. Make sure you document machine-specific procedures and specific steps to isolate, secure and shut it down.

– Implement comprehensive training sessions and make sure the employees have a clear understanding of safety procedures and the magnitude of hazardous energy sources within the facility.

– Sort out your workers according to their lockout responsibilities. Anyone unaware of the health hazards and safety procedure shouldn’t be allowed near the machineries but still must receive basic instructions regarding energy control. As an employer, it is your responsibility to protect all the workers.

And lastly, keep reviewing and updating your safety program. Just like machinery, a lockout safety program requires periodic reviews.

Checkout Our Other Lockout Tagout Products:

- Valve Lockout

- MCB Lockout

- Lockout Padlocks

Enquire Now

Safety House Loto Products For Safe Work Environment

What is a Lockout/Tag out?

The logout/tag out is abbreviated as LOTO these are practices and procedures are now a days a very common practice which means shutting off the dangerous machines which contains hazardous waste like lubricating oils, smoke and degradable products which may harm the environment and not able to start them until and unless completion of maintenance or servicing work is done.Safety House Loto Products

While servicing is done hazardous energy is isolated and inoperative because if this hazardous waste is let free in the air might create a severe problem. After the service is done the service man hen locked and a tag is placed on the lock identifying the worker who has placed it which again states that this practice is a useful and safe practice for both the employee and environment as well. There are special devices designed and applied according to the nature of hazardous energy and nature of use which does not allow disposing of this hazardous waste into the open air. All these devices have the main motive of ensuring the workplace safety of all the individuals who are working under the organization.

There are various kinds tag out devices which can be used depending on the needs and interests of the hiring organizations and firms. Below stated are some different types of lockout devices with the name and nature of its use.

(1) Adjustable Ball valve locks are the most prominent devices used now a days in industry because they are easy to install and does not allow the easy disposed off the fluids nature of molecule as the application is the most simplest of all the tag out devices.

(2) Valve Lockouts are kind of caps which are placed on the rotating type valves, these are very easy to install and effective when in use.

(3) Safety Locks as the name suggest are the simple locks used at the storage areas where the hazardous waste is kept off to lock some operating rooms which are not in use of a room where the entry in only done when a person is able to fulfil the safety parameters as per required.

(4) Hubell Plugout used where the wires with plugs in front and the wires are not in use for some time. These are used to avoid the damage of the plug and as the material of the plug are plastic which may lead to damaging the environment as well.

(5) Circuit breaker lockout as the name suggest these are used where the electrical panel is installed and these helps in achieving operator safety.

Conclusion

There are many more which can be used but some of the basic tag out or lockout devices for the workplace safety are jotted down in the information stated above. Hence, we can conclude by remarking that the tag out devices can be used for the betterment of the environment of any organization as well as the proper safety of the employees working in that particular firm too.Safety House Loto Products

Checkout Our Other Lockout Tagout Products:

- Valve Lockout

- MCB Lockout

- Lockout Padlocks

Enquire Now

Never Ignore Workplace Safety

If we say that a belonging can come in a working environment that can only be achieved or attained by keeping the employee safe, if a employee is not safe or does not have safe working environment he/she will never be happy will not religiously work for you and may commit mistakes while working, the mistake can go up to that extent that a working operator can meet with a sever accident and can lead death. Workplace Safety

Definition of Safety

Safety as the word suggest means creating safe working environment like having sufficient amount of light while doing so critical work, optimum exhaust openings while doing some job which may include use of hazardous effluents, use of gloves while working on machines, use of helmet when working on height, wearing shoes when in workshops. Ergonomics is also considered as one of the most important part of occupational health and safety as a proper layout is made and the execution is laid accordingly helps in reducing the chances of workers fatigue. This applies not only to those working on computer workstations but also to those using equipment which are controlled from one place. The principles of ergonomics apply to all workers who spend hours sitting in the same position.

There is one procedure called LOTO (Logout/Tagout) which means no equipment containing hazardous will be back into proper functioning until and unless the hazardous waste has been properly disposed off. These regulations highlight the employer’s responsibility to protect workers from hazardous energy sources, with managers encouraged to develop safety programs that are best suited to their facility. There are many kinds of the Loto Products which help in maintaining the workplace safety for the organization as well as that of the employees of the organization but also in ensuring the ignorance and prevention of various mishaps.

The application of these devices is most common in pipelines where the use of valve is frequent.

(1) Adjustable Ball Valve lockout are the locks fitted on the handles to avoid the escape of the hazardous fluids from the pipe lines.

(2) Valve locking covers are used on the valve having handle made of round shape. These are used to avoid the twisting of the handle of the valve and avoid the flow of the fluid containing element that can harm the environment.

(3) Locks and key safety systems are the system applied where there is a separate room to keep the hazardous waste and used in operating rooms as well as used in FMGC units where safety is considered the top most requirements.

(4) Circuit Breaker locks are used to avoid any accident related to electricity and used where there is complete shut down in the plant.

(5) Hubbell Plugout is the types of locks used particularly on wire having chords attached to it. Chords are nothing but special plug attached to wire to make connection in some electronic devices. The plug outs are used to cover these chords so that the chords are not broken and damaged due to any means as the material used to make chords in plastic which is very harmful for environment as it non bio degradable product.

Conclusion

In all, the loto products with time have proven to be great supporters and helpers when it comes to the safety of the firm and its people. The use of such products should be on a higher note for the sake of individual safety because nothing is more important than the health and safety of any individual be it a worker or the owner of the enterprise. Workplace Safety

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- LOTO KIT

Enquire Now

Best Ways To Avoid Conflict With OSHA

It is said that smart people are those who learn from their own mistakes. But smartest are the ones who learn from the mistakes committed by others. Today we bring you a very interesting blog regarding how you can avoid getting in trouble with OSHA (Occupational Safety and Health Administration). manufacturer of lockout products

It has happened numerous times when industrial men won’t listen to OSHA and completely ignore their prescribed guidelines of implementing Lockout Tagout system in order to secure the workplace and the life of the staff employed. This often leads to conflicts with the supervising establishment and it is advisable to never disrespect your bread and butter. Reason being OSHA has the right to shut down a firm or extricate the employed staff from the organizations where the guidelines aren’t followed.

So, if you want to steer clear of facing any kind of trouble with OSHA and wish to eschew any catastrophic accident happening in your organization, keep note of the following things: –

Ensure your Lockout-Tagout practices are appropriate to the way they are prescribed in OSHA’s guidelines to safeguard the employees against possible injuries such as amputations, or even death. Always ask OSHA for any query if you may have any.

Always report about damaged or missing guards and never ever bypass a moving device. Until and unless the damaged machinery is repaired or replaced, make sure all of your workers are taking necessary precautions.

Update yourself with all the MSDS information of the chemicals that are used by you and your employees on site. Ensure you are providing protective workshops and training to the staff.

Considering most of the injuries happen due to lack of safety operating procedures, deficient safety-rule and inadequate training given to employees, always make sure your establishment never falls into any of these three categories.

Learn to use cords flexibly. Practice running extension cords overhead or taping them down to avoid tripping.

It is hard to keep track of all the safety guidelines prescribed by OSHA so at least by adhering to the above mentioned techniques, you can hope for a secure workplace and obviously manage to keep OSHA away from raining down on you. For more relevant information regarding Lockout-Tagout procedure, stays tuned to our blog and if interested in purchasing LOTO Kit, feel free to order online because we are the best Lockout-Tagout product manufacturer in India.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Things To Expect During OSHA Inspection

OSHA (Occupational Safety and Health Administration) is both a Jedi and Darth Vader for the industrial companies. One way it shows light to those who seek help, while on the other hand it latches the firm which doesn’t obey the rules or set of guidelines established by them. Often employers feel scared of undergoing an OSHA inspection counting they don’t follow the guidelines. Lockout Tagout Products

It has been observed several times that the employers who got in conflict with OSHA were not fully aware about the things to expect from an inspection. Since it is not a general school probe so understanding the things that have to be done in order to protect yourself from any sort of trouble is important.

The Inspection comprises of three stages of which the first one is opening conference, then a factory walk-through, followed with a closing conference. Make sure to greet the inspector when they arrive and check their credentials. It is important to ask for the reason behind their visit in order to know whether they have come on a programmed inspection or for a complaint done by some employee.

The must have records to be submitted to OSHA for examination includes the following: –

1. Injury/Illness records upto last five years.

2. A descriptive hazard communication program.

3. Emergency evacuation procedures.

4. Descriptive Lockout Tagout Programs.

5. Medical Records.

6. Material Safety Data Sheets (MSDS).

7. Bloodborne pathogen Training Documentation.

8. Respirator Programs.

The scrutiny may cover all or partially your facility as an OSHA inspection is not restricted to a certain area. And if the compliance officer finds anything suspicious in open view, they have the right to expand the examination. Also, make sure to not delay the OSHA Inspection considering asking for too much time may raise their doubts and more likely the next inspection will be more comprehensive than the first.

Also, do not forget to fix the problems that the inspector notes before they leave the building. It is advised that you review the examination with the team itself. Alright, that’s it for today. Stay tuned to our blog for more relevant information regarding Lockout-Tagout procedure. And if interested in buying LOTO Kit, feel free to order them online because we, at Safety House, are the best Lockout Tagout Product Manufacturer in India.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Learn About Lockout Tagout Procedure To Control Hazardous Energy

Lockout-Tagout procedure is a very safe and serious practice of safeguarding the workers from the potential threat of unanticipated release of harmful gases or other forms of energies. It is an integral part of workplace security and an OSHA standard which demands the employers to create a LOTO system for their establishment. According to some recent stats uploaded by OSHA, Lockout-Tagout process helps prevent approximately 50,000 injuries and 120 deaths

of employees per annum. It is a sentry technique of protecting the workers by making sure that no noxious devices can operate sporadically on their own via turning off and locking out the equipments appropriately.

The primary steps of Lockout-Tagout procedure are:

1. Person in-command must ponder through the entire process.

2. He or she must recognize all parts of the system that needs to be turned off.

3. Should select wisely as to what switches, devices and people will be involved in the procedure.

4. Must formulate the plan cautiously as to how the device will be restarted.

Furthermore, the person in-charge must properly communicate with the team. Improper communication can lead to misunderstandings regarding specific tasks to execute in the process. Also, the workforce not involved in Lockout safety procedure must be alerted about it. All kinds of recognizable electrical circuits, hydraulic and gravity systems, etc must be disconnected from the power source. The movable parts must be blocked and the dangling parts must be put to resting positions.

Once the process has been carried out, double checks must be performed to ensure that no loose ends were left. And when it’s the time to reenergize the equipment, proper inspection must be done to make sure that the machine is kept intact as it was left out and all the unnecessary items lying around should be removed.

Lockout-Tagout Products has considerable benefits and it is suggested that one must follow the program and provide essential training to his or her employees.

Checkout Our Other Lockout Tagout Products:

- Lockout Hasp

- Group Lockout Box

- Lockout Station

- Valve Lockout

Enquire Now