Lockout Kit Essentials for Different Industries: Tailoring Safety Solutions

Introduction

In industries where machinery and equipment pose significant safety risks, a well-organized lockout/tagout (LOTO) kit is crucial for ensuring worker safety. Lockout kits are essential tools that help prevent accidental machine start-ups during maintenance or repair activities. However, different industries have unique requirements, and tailoring lockout solutions to these specific needs is vital. Safety House Loto offers comprehensive lockout/tagout products designed to meet these diverse demands.

Why Lockout/Tagout Kits Are Important

Lockout/tagout kits play a pivotal role in protecting workers from hazardous energy sources during maintenance or service operations. By using a LOTO kit, you ensure that machines are properly shut down and cannot be accidentally reactivated, thus preventing injuries and fatalities. The effectiveness of these kits depends on their suitability for the specific machinery and environment in which they are used.

Tailoring Lockout Kits for Different Industries

1. Manufacturing

In manufacturing settings, lockout/tagout kits need to address various types of machinery, including presses, conveyors, and injection molding machines. Essential components of a manufacturing LOTO kit typically include:

- Padlocks: Durable and high-security lockout padlocks to lock out machinery.

- Hasps: Multi-lock hasps to accommodate multiple lockout points.

- Tags and Labels: Clear and durable tags to indicate that machinery is under maintenance.

2. Construction

Construction sites present unique challenges for lockout/tagout due to the variety of equipment and energy sources used. A construction-specific lockout kit should include:

- Lockout Devices for Electrical Panels: Devices to isolate electrical sources, such as circuit breaker lockouts.

- Valve Lockouts: For controlling the flow of hazardous substances through pipes and valves.

- Portable Lockout Kits: Easy-to-carry kits for use across different job sites.

3. Oil and Gas

The oil and gas industry requires robust lockout/tagout solutions due to the high-risk environment and complex machinery involved. A specialized lockout kit for this industry might include:

- High-Temperature Lockout Devices: To withstand extreme conditions.

- Pneumatic Lockouts: For isolating pneumatic energy sources.

- Custom Tags: To comply with industry-specific safety standards and regulations.

4. Utilities

Utility companies deal with large-scale electrical and mechanical systems that require comprehensive lockout/tagout solutions. Essential components for a utility lockout kit include:

- Electrical Lockout Devices: For isolating high-voltage circuits.

- Valve Lockout Devices: For controlling utility pipelines.

- Lockout Tags: To provide clear, informative warnings.

Key Considerations When Choosing a Lockout Kit

1. Compliance with Regulations

Ensure that your lockout kit meets the safety standards and regulations applicable to your industry. Compliance helps in avoiding legal issues and ensures worker safety.

2. Customization

Choose a lockout kit that can be customized to fit the specific needs of your equipment and work environment. A tailored kit ensures that all potential energy sources are properly addressed.

3. Quality and Durability

Invest in high-quality, durable lockout/tagout products that can withstand the rigors of your industry. Reliable products contribute to effective safety management and long-term cost savings.

Conclusion

Lockout/tagout kits are essential for maintaining a safe working environment across various industries. Tailoring these kits to the specific needs of your industry ensures that all potential hazards are effectively managed. Safety House Loto provides a range of lockout tagout products designed to meet the unique requirements of different sectors. By investing in a customized lockout kit, you protect your workforce, comply with safety regulations, and enhance overall operational efficiency.

The Ultimate Guide to Lockout Kits: Choosing, Implementing, and Enhancing Safety Measures

Lockout kits, also known as LOTO kits, are an essential component of workplace safety. These kits provide workers with the necessary tools and equipment to isolate machinery or equipment from its energy source during maintenance or repair work. Failure to implement proper lockout procedures can result in serious injuries or even fatal accidents. In this ultimate guide, we’ll explore the different types of lockout kits available on the market today and discuss what you need to look for when choosing one for your business. We’ll also cover how to implement a lockout kit effectively and enhance overall safety measures in your workplace. So let’s dive in!

What Is A Lockout Kit?

A lockout kit, also known as a LOTO kit, is a collection of tools and equipment designed to help workers isolate machinery or equipment from its energy source. Lockout kits typically consist of padlocks, hasps, tags, circuit breakers, and other safety devices that prevent the accidental release of hazardous energy.

When using a lockout kit, workers are required to follow specific procedures before performing maintenance or repair work on the equipment. These procedures involve isolating the energy source and ensuring that it cannot be re-energized until work is completed.

Lockout kits can come in various sizes and configurations depending on the type of machinery or equipment being serviced. Some kits may include specialized devices such as valve lockouts or electrical disconnects for specific applications.

Implementing proper lockout/tag-out procedures with a lockout kit helps ensure worker safety by preventing accidents caused by unexpected energization during servicing activities.

The Different Types Of Lockout Kits

Lockout kits come in various forms to cater to different industries and applications. The types of lockout kits that are available include electrical, mechanical, pneumatic, hydraulic, and combination lockout kits.

Electrical lockout kits are designed to prevent the accidental or unauthorized operation of electrical equipment during maintenance or repair work.

Mechanical lockout kits contain devices such as lockout padlocks and loto hasps which can be used to secure machinery with moving parts.

Pneumatic lockout kits prevent compressed air from being released accidentally during servicing procedures on pneumatically operated machines.

Hydraulic lockout kits similarly protect against any hydraulic energy that could potentially harm workers when working on hydraulic-powered systems.

Combination lockout kits may include a mix of devices from each category depending on the specific needs of a workplace.

When choosing a type of kit, it is important to ensure that it meets all relevant safety standards for your industry and application.

Pros and Cons Of a Lockout Kit

A lockout kit is an essential tool for any workplace that uses heavy machinery or equipment. It enables workers to safely shut down and isolate the energy source of a machine, ensuring that no one can accidentally start it up again while repairs are being made.

One of the major advantages of a lockout kit is increased safety. By making sure machinery cannot be turned on during maintenance or repairs, employees are protected from potentially dangerous accidents. Another benefit is compliance with OSHA regulations; using a lockout kit demonstrates a commitment to worker safety, which can prevent costly fines and lawsuits.

However, there are some downsides to using a lockout kit. One potential issue is decreased productivity, as shutting down machinery takes time away from production. Additionally, if not used correctly or consistently by all employees, a lockout system could lead to confusion and mistakes.

The benefits of implementing a reliable lockout system far outweigh any potential drawbacks. With proper training and usage guidelines in place, businesses can ensure their workers’ safety while maintaining efficient operations.

What to Look for When Choosing a Lockout Kit?

When it comes to choosing the right lockout kit for your workplace, there are several factors that you should consider. First and foremost, you must ensure that the kit meets all relevant safety standards and regulations.

Another important consideration is the size of your facility. If you have a large facility with many different types of machinery and equipment, you may need a more comprehensive lockout kit that includes a wide range of devices and tools.

It’s also important to choose a lockout kit that is easy to use and understand. Look for kits with clear instructions and diagrams so that employees can quickly learn how to properly secure equipment during maintenance or repair work.

Durability is also crucial when selecting a lockout kit. Your chosen kit should be able to withstand frequent use in harsh industrial environments without breaking down or losing effectiveness over time.

Consider purchasing from reputable manufacturers who offer good quality customer service, warranties, and technical support. This ensures that any issues or questions will be addressed promptly if they arise in the future.

Implementing a Lockout Kit

Implementing a lockout kit is an essential step in ensuring the safety of workers who operate machinery and equipment. The process involves creating standard procedures to isolate energy sources before performing maintenance or repairs.

The first step in implementing a lockout kit is to identify all possible energy sources that could cause harm. This includes electrical, hydraulic, mechanical, pneumatic and chemical energy sources. Once identified, each energy source must be isolated using the appropriate locks and tags from the kit.

It’s crucial to train employees on how to use lockout kits correctly as part of their job responsibilities. This training should emphasize the importance of following procedures strictly for every machine they work with.

After implementing a lockout procedure, it’s essential to conduct regular audits and inspections to ensure employee and management compliance. These assessments help identify any gaps in implementation so that corrective measures can be taken before accidents occur.

Implementing a lockout kit requires careful identification of potential hazards followed by strict procedural guidelines for isolating those hazards through locking out all forms of hazardous energy sources.

This ensures worker safety when maintaining or repairing machines while also reducing risks associated with such equipment operations.

Enhancing Safety Measures with a Lockout Kit

Lockout kits are a valuable tool for ensuring the safety of employees who work in settings where hazardous energy sources are present. However, simply having a lockout kit is not enough to guarantee workplace safety. It’s crucial to implement proper procedures and protocols to ensure that the kits are being used correctly.

One way to enhance safety measures with a lockout kit is by creating written procedures outlining how and when the equipment should be used. These procedures should include information on which machines or equipment require locking out, as well as specific steps for using the lockout kit properly.

Another important step in enhancing safety measures with a lockout kit is training employees on proper usage and maintenance of the equipment. This includes teaching them about different types of energy sources, identifying potential hazards, and demonstrating how to use each component of the kit.

It’s also essential to regularly inspect all lockout devices and replace any damaged or worn-out components promptly. Keeping an inventory of your company’s current supplies can help you stay ahead of future needs so that you’re never caught without necessary items.

It’s always wise to review your LOTO program periodically; this ensures that everything continues running smoothly while addressing changing conditions or needs within individual departments. With careful planning and attention-to-detail during implementation, businesses can successfully improve their overall level of workplace safety through comprehensive LOTO programs bolstered with reliable tools such as quality Lock Out/Tag Out (LOTO) Kits.

Conclusion

Lockout kits are an indispensable tool for keeping employees safe while working on potentially dangerous machinery or equipment. By using lockout kits, employers can effectively prevent accidents caused by unexpected start-ups and releases of stored energy.

When choosing a lockout kit, it’s important to consider the specific needs of your workplace and ensure that the kit includes all necessary components. Once implemented, it’s crucial to train employees on how to properly use the kit as part of their safety training.

Enhancing safety measures with a lockout kit doesn’t have to be complicated or expensive. By following best practices and regularly reviewing your procedures, you can create a safer work environment for everyone involved.

Investing in high-quality lockout kits is essential for any organization looking to prioritize employee safety. Taking the time to choose the right kit and properly implement its usage will go a long way towards preventing accidents in your workplace.

Checkout Our Popular Products:

- Osha lock

- Lockout station

- Scaffold Tag

- MCB Lockout

How to Use Electrical Lockout Devices and Equipments?

When utilized in industrial high voltage or low voltage applications, electrical lockout devices may help prevent electrical accidents by ensuring that electrical systems are properly shut off. One of the most common methods of preventing accidental or unintentional access to electrical power sources is implementing a Lockout-Tagout technique (LOTO).

Using this secure process, every person working on the same circuit or piece of equipment has a lock that they fasten to a disconnect device before starting their job.

Lockout operations are complete when the disconnect switch or isolation device is free of all locks and lockout devices, indicating that the last worker has granted permission for the line to be re-energized after the lockout operation has been completed.

Procedure to Use the Electrical Lockout Tagout Devices

A normal lockout Tagout method calls for locating all possible power sources. A qualified worker must properly inform on the scope of the operation before they shut down the line or circuit. The following are some of the methods on how to use Electrical Lockout Devices and Equipment.

Locate the process that will follow

Binders or lockout Tagout software may use in your organization. First, locate the steps to use electrical lockout devices necessary for the machine you will be working on and follow them to completion.

According to the manufacturer’s recommendations, this technique should describe the step-by-step approach for shutting down and restarting the equipment. Read More: What Are The Usage Of Electrical Plug Lockouts?

Notify any concerned persons

Any work on the equipment must complete only after all co-workers, contractors, and other parties who may inform of the project’s progress. In addition, if any adjustments need to be made to work procedures, make sure that everyone is informed of these changes.

Find all energy sources

The Lockout Tagout technique you are using should include all of the energy sources that need to be disconnected or isolated. It may even be able to produce images that reveal the specific position of the harmful energy source. Read More: Electrical Panel Lockout Switches With Safety

Turn off the machine

The lockout Tagout method should include a list of the procedures to be taken to do this and specific instructions on how to shut down the equipment. Some devices or equipment need several steps to be completed before they may be shut down. Moreover, Valve Lockout is the major equipment that is used to block harmful and hazardous materials from pipes supplies.

Lockout and tag all energy isolators

Make use of the locks and tags that have been assigned to you. In most cases, this requires permission. If more than one person is engaged in the maintenance or service of the machine or equipment, each individual must connect their lock or tag to the energy isolating device.

From the Loto Kit, using Electrical Lockout Devices and Equipment can improve employee productivity and efficiency. It also prevents issues from arising in the first place, which leads to a safer working environment.

These are the Popular Safety House LOTO Products

>> MCB Lockout

>> Group Lockout Box

>> Scaffold Tag

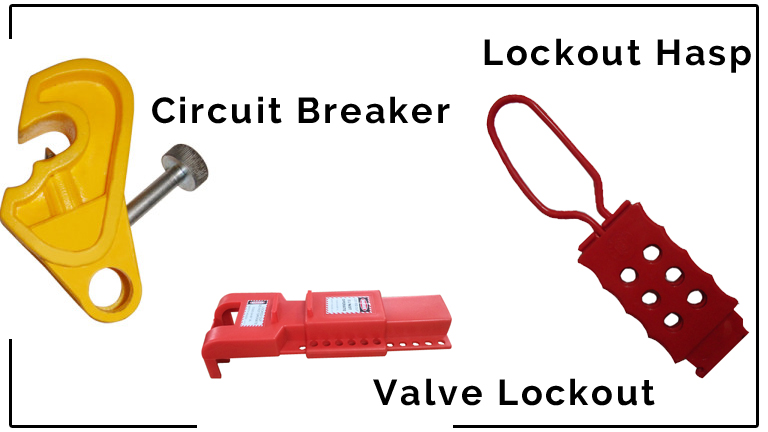

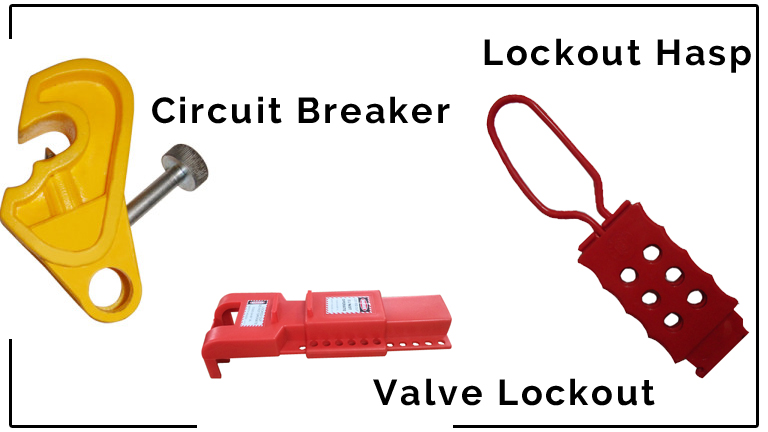

3 Common LOTO Safety Range Of Products

Hasps – At ‘Safety House – LOTO’, the best manufacturer of lockout products in India, the product range of hasps includes dielectric hasp, double jaw hasp/ dual jaw hasp and electroplated hasp. But what is a hasp? And what do they do? More than one worker often performs repair/ maintenance on a piece of equipment. Ideal for group lockout procedures, a hasp lets more than one worker to put padlock and lockout an energy source. It ensures that they remain safe. lockout supplier

Circuit Breaker Lockout – Our website ‘Lockout India’ lists an impressive range these LOTO devices that are used to isolate a particular breaker in a circuit breaker panel. Have a look at our Circuit Breaker Lockout page to see our large circuit breaker lockout, MCB lockout, MCB pin lockout, mini circuit breaker lockout and more. These lockout the breakers of all major brands. Once a breaker has been isolated, the whole breaker box doesn’t require locking out.

Valve Lockout – Valve lockouts are used for shutting off gas or fluid valves. Preventing these valves, including ball valve (Commonly used handles that are turned at 90° to shut off.), cylinder valve, butterfly valve and gate valve (These are round knobs.), from opening is important, when repair work/ maintenance is being performed. While gate valve lockouts are measured by their diameter, ball valve lockouts are determined by the handle length. You may also like to have a look at our butterfly valve lockout.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now