Lockout Hasps for Small Businesses: Affordable Safety Solutions

The small business sector is faced with unique challenges in terms of safety for the employees. Due to the unavailability of funds, small teams, and diverse responsibilities, developing safety measures should be used as the base guidelines for hire affordableand efficient. In that sense, Safety House LOTO has been able to come to their rescue by supplying Lockout Hasps to ensure workplace safety in these very demanding, machinery and electric equipment-driven operational environments.

What Are Lockout Hasps?

Lockout Hasps are safety devices designed to lock out energy sources during equipment maintenance or repair. These devices allow multiple workers to secure a machine or electrical panel by attaching their personal padlocks to the hasp. This ensures that the equipment remains inoperative until all locks are removed, safeguarding workers from accidental startups or energy release.

Why Are Lockout Hasp Essential for Small Businesses?

Small businesses are often on tight budgets and cannot take risks with workplace accidents. Amy form of injury can lead to financial losses, legal liabilities, and downtime, which can really cripple the operation. Lockout Tagout (LOTO) products, including Lockout Hasps, are a worthwhile shield in that they are affordable and simple solutions to avoid any such catastrophe by locking out dangerous machinery or process.

1. Cost-Effective Safety

For small businesses, affordability is key. Lockout Hasp are relatively inexpensive compared to other safety measures. Their durable design and reusability make them a one-time investment with long-term benefits.

2. Versatility Across Industries

Whether you run a small manufacturing unit, a workshop, or a retail outlet with basic electrical systems, Lockout Hasp can be adapted to various equipment types. They are particularly useful for machines with multiple energy sources, where multiple workers need to secure the system.

3. Compliance with Safety Regulations

Adhering to workplace safety regulations is essential for businesses of all sizes. LOTO systems, including Lockout Hasp, help small businesses comply with Occupational Safety and Health Administration (OSHA) guidelines or similar regulatory requirements, reducing the risk of penalties.

How Lockout Hasps Work

The simplicity of Lockout Hasps is one of their strongest features. Here’s how they function:

- Placement: The hasp is placed through the energy isolation point, such as a switch or valve.

- Locking: Each worker involved in the maintenance attaches their personal lock to the hasp.

- Team Safety: The machine cannot be reactivated until every lock is removed, ensuring collective safety.

This collaborative approach to safety is particularly beneficial in workplaces with multiple employees handling the same equipment.

Types of Lockout Hasps

Small businesses can choose from a range of Lockout Hasps to suit their specific needs:

1. Standard Lockout Hasp

These are basic hasps made of durable materials, suitable for general-purpose use.

2. Insulated Lockout Hasp

Ideal for electrical applications, these hasps are coated with non-conductive materials to enhance worker safety.

3. Heavy-Duty Lockout Hasp

For machinery with high energy levels or challenging environments, heavy-duty hasps provide added durability and reliability.

Benefits of Using Lockout Hasps

1. Enhanced Worker Safety

By preventing unauthorized access to equipment, Lockout Hasps reduce the risk of accidents caused by unexpected startups.

2. Promotes Accountability

Each worker uses their lock, ensuring personal responsibility for safety during maintenance.

3. Simplified Processes

The ease of use makes Lockout Hasp accessible for small businesses, even with limited training resources.

4. Long-Term Durability

Built to withstand tough conditions, Lockout Hasps offer long-lasting protection, making them a cost-effective choice for safety.

Integrating Lockout Hasps with Lockout Tagout Products

While Lockout Hasps are critical, their effectiveness is amplified when integrated into a comprehensive Lockout Tagout system. Other essential LOTO products include:

- Padlocks: Used in conjunction with hasps to secure energy sources.

- Tags: Provide clear communication about the locked-out equipment, including who locked it and why.

- Valve and Circuit Breaker Locks: Specialized devices for isolating specific types of energy sources.

Small businesses can create a robust safety framework by combining these products, ensuring a safer workplace.

Choosing the Right Lockout Hasps for Your Business

When selecting Lockout Hasps, small businesses should consider:

- Material: Opt for durable materials like steel or non-conductive coatings, depending on the application.

- Size and Design: Ensure compatibility with your equipment’s energy isolation points.

- Ease of Use: Choose hasps that are simple to implement, especially if your team is new to LOTO practices.

Conclusion

To small businesses, safety does not mean spending a lot. Lockout Hasps provide an effective and affordable answer to workplace accidents and safety regulations compliance. Their affordability, versatility, and durability make them an indispensable item you may find in any Lockout Tagout system.

Quality LOTO products protect employees while cutting down on downtime, allowing a culture of safety to develop in businesses. Be they small workshops or a small enterprise that is looking to develop, the inclusion of the Lockout Hasps will serve as a forward step towards a safe and high-performing workplace.

Lockout Padlocks vs. Standard Padlocks: What’s the Difference?

When it comes to workplace safety, understanding the tools designed for specific tasks is critical. Padlocks, for example, are commonly used for securing property or equipment. However, when safety is a concern, Lockout Padlocks play an essential role. At first glance, these might seem similar to standard padlocks, but their purpose, design, and functionality are distinct. Let’s explore the key differences between lockout padlocks and standard padlocks, emphasizing their role in enhancing safety through Lockout Tagout (LOTO) systems.

What Are Standard Padlocks?

Standard padlocks are everyday security tools designed to protect valuables and restrict unauthorized access. You’ll typically find them securing gates, lockers, or cabinets. Key features of standard padlocks include:

- Purpose: Focused on theft prevention.

- Design: Made with robust materials like steel to resist tampering.

- Key Systems: Often shared or interchangeable keys, convenient for general use.

While these padlocks are effective for securing physical property, they lack the specialized features required for workplace safety systems.

Understanding Lockout Padlocks

Lockout Padlocks are specially designed for use in Lockout Tagout (LOTO) systems, ensuring the safety of workers during equipment maintenance or servicing. Key characteristics include:

- Non-Conductive Materials: Many lockout padlocks are made with non-conductive materials like plastic or nylon to prevent accidental electrical conduction.

- Unique Key System: Each lockout padlock has a unique key, ensuring that only authorized personnel can remove it.

- Durable Tags: Often accompanied by tags or labels for clear communication, identifying who locked the equipment and why.

- Color Coding: Available in various colors for quick identification, aiding in organizing multiple lockout procedures.

These features make lockout padlock indispensable for isolating energy sources and preventing accidental equipment activation.

Key Differences Between Lockout Padlocks and Standard Padlocks

1. Purpose

- Standard Padlock: Focused on securing property and preventing theft.

- Lockout Padlock: Specifically designed for safety purposes, ensuring equipment remains de-energized during maintenance.

2. Material Composition

- Standard Padlock: Typically made of metal for durability and security.

- Lockout Padlock: Often feature non-conductive materials, ensuring safety in environments with electrical hazards.

3. Keying Systems

- Standard Padlock: Keys can be duplicated or shared for convenience.

- Lockout Padlock: Feature a unique key-to-lock ratio, preventing unauthorized removal and enhancing safety protocols.

4. Design and Visibility

- Standard Padlock: No specific emphasis on visibility or labeling.

- Lockout Padlock: Bright colors and customizable labels make them highly visible and informative.

Why Are Lockout Padlocks Essential for Safety?

Lockout Padlocks form a vital part of the Lockout Tagout (LOTO) system, a safety protocol mandated by regulatory bodies like OSHA. These padlocks help in:

- Energy Isolation: Ensuring all energy sources are locked out before maintenance begins.

- Accident Prevention: Preventing accidental activation of machinery, reducing risks of injuries or fatalities.

- Accountability: Clear labeling and unique keys ensure only authorized personnel can access locked-out equipment.

By using lockout padlock, businesses can meet safety compliance standards and foster a safer workplace environment.

How to Choose the Right Lockout Padlocks?

When selecting lockout padlocks, consider the following:

- Durability: Opt for locks resistant to harsh environments.

- Non-Conductive Materials: Essential for electrical applications.

- Key Management System: Ensure a unique key system to prevent duplication.

- Compatibility with Tags: Ensure they work seamlessly with lockout tags and devices.

Reputable lockout suppliers, like Safety House Loto, provide high-quality Lockout Tagout products, including padlocks that meet industry standards.

Conclusion

While standard padlocks are great for securing physical property, lockout padlocks are an essential component of workplace safety. Designed to prevent unauthorized access and accidental activation of equipment, they are a cornerstone of any Lockout Tagout system.

For businesses prioritizing safety, choosing the right lockout products is crucial. Partnering with reliable lockout suppliers, such as Safety House Loto, ensures you get top-notch solutions tailored to your needs. By investing in lockout padlocks and adhering to LOTO protocols, you can create a safer and more compliant workplace.

Understanding the difference between these two types of padlocks not only helps in selecting the right tools but also reinforces the importance of safety in every industry.

Why Every Facility Needs High-Quality Lockout Padlocks: Top Reasons and Benefits

In today’s industrial environment, ensuring worker safety is a top priority. One of the most effective ways to maintain safety in hazardous workspaces is through the use of Lockout Tagout (LOTO) systems. Lockout Padlocks, a critical component of LOTO, help prevent accidental machine startups during maintenance or repair activities. This blog explores the top reasons why every facility should invest in high-quality Lockout Padlocks and the benefits they provide.

1. Prevent Accidental Machine Startups

One of the primary reasons for using Lockout Padlocks is to prevent accidental machine activations. During equipment maintenance or repair, the unexpected startup of machinery can lead to severe injuries or even fatalities. By using Lockout Tagout products, including padlocks, workers can securely isolate energy sources and prevent unintentional reactivation.

How Lockout Padlocks Work: Lockout Padlocks are designed to fit onto energy control devices like circuit breakers, valves, and switches. When locked, the machinery or system remains inoperative, ensuring that only authorized personnel can remove the lock and restart the equipment after the maintenance is complete.

2. Comply with Safety Regulations

Adhering to industry safety standards is not just about preventing accidents—it’s also about legal compliance. Many countries have stringent regulations mandating the use of Lockout Tagout systems, such as OSHA (Occupational Safety and Health Administration) in the United States. Failure to comply with these regulations can lead to hefty fines and penalties. High-quality Lockout Padlocks ensure your facility meets these safety standards, protecting both your employees and your business.

3. Protect Employees and Minimize Downtime

Another significant advantage of using high-quality Lockout Padlocks is the protection they provide for your workforce. Employee safety is paramount, and a well-implemented LOTO system drastically reduces the risk of workplace accidents. By safeguarding workers from hazardous energy, Lockout Padlocks allow maintenance and servicing tasks to proceed without fear of sudden machine startups. This protection ultimately minimizes injuries, enhances productivity, and reduces downtime associated with accidents.

4. Customize Your Lockout System

Lockout Padlocks are versatile and can be customized to meet the specific needs of your facility. Many manufacturers offer padlocks in various sizes, colors, and keying options. These customizations allow for efficient lockout procedures, helping workers quickly identify which energy sources are locked out and who is responsible for the lock. Customizing your Lockout Tagout products ensures that your system is both effective and easy to use.

Examples of Customization Options:

- Color Coding: Different colors can be assigned to various departments or types of equipment.

- Keying Options: Padlocks can be keyed differently for each user or keyed alike for shared access.

5. Enhance Security with High-Quality Materials

When it comes to Lockout Padlocks, quality matters. Investing in durable, tamper-resistant padlocks made from high-grade materials ensures that your LOTO system is robust and secure. High-quality padlocks are designed to withstand harsh industrial environments and offer superior resistance to tampering or accidental damage. Choosing reputable Lockout Tagout products increases the longevity of your system and ensures that your workers remain protected.

6. Promote a Safety-First Culture

Investing in a high-quality LOTO system, including Lockout Padlocks, sends a clear message to your employees: safety comes first. By implementing effective safety measures, companies foster a safety-first culture where workers feel valued and protected. This positive environment encourages adherence to safety protocols, reducing accidents and increasing workplace morale.

7. Versatile Application Across Industries

Lockout Padlocks are not limited to a specific industry. Whether you’re in manufacturing, energy, chemical processing, or transportation, Lockout Tagout products can be used to isolate hazardous energy sources. Facilities with complex machinery or high-risk operations can especially benefit from the added layer of protection that Lockout Padlocks provide.

Conclusion: Invest in Safety with Lockout Padlocks

High-quality Lockout Padlocks are an essential component of any safety-conscious facility. By preventing accidental startups, complying with regulations, protecting employees, and promoting a safety-first culture, these padlocks provide substantial benefits across industries. Safety House Loto offers a wide range of Lockout Tagout products designed to meet the highest safety standards, helping facilities worldwide ensure worker protection.

Incorporating Lockout Padlocks into your LOTO system is a smart investment that protects your workforce and minimizes the risk of accidents. Whether you need customized solutions or high-quality padlocks that withstand industrial environments, ensuring you have the right products in place is essential for a safe and compliant workplace.

Beyond the Lock: Essential LOTO Accessories for Enhanced Safety

Enhancing Workplace Safety with Essential LOTO Accessories

In any industrial setting, safety is paramount. One of the most critical safety protocols is Lockout/Tagout (LOTO), which is designed to protect workers from hazardous energy during maintenance and servicing of machinery. While the basic lockout devices are essential, several accessories can enhance the effectiveness of a LOTO program. Safety House Loto, a leading manufacturer of lockout products, offers a range of LOTO accessories that go beyond the standard lock and tag to ensure maximum safety.

The Importance of LOTO Accessories

Lockout Tagout products are not just about preventing accidents; they are about creating a comprehensive safety system that addresses all potential risks. Accessories complement the primary lockout devices, offering additional layers of protection and convenience. Here’s a closer look at some essential LOTO accessories that can significantly enhance workplace safety.

1. Lockout Hasps

Enhanced Multiple Lock Capability

Lockout hasps are indispensable in situations where multiple workers need to lock out a single energy source. By allowing multiple padlocks to be attached to a single hasp, they ensure that the machinery cannot be re-energized until each worker has removed their lock. This guarantees that all team members are aware and confirm the machine is safe to operate.

2. Safety Lockout Boxes

Centralized Control and Management

Safety lockout boxes serve as a centralized point for managing locks and keys during a lockout procedure. These boxes can hold keys from lockout points, ensuring that all keys are controlled and accounted for. Only authorized personnel can access the lockout keys, enhancing security and ensuring that the equipment cannot be accidentally re-energized.

3. Lockout Tagout Stations

Organized and Accessible

Keeping LOTO devices organized and easily accessible is crucial for efficient safety procedures. Lockout tagout stations are wall-mounted boards or cabinets that store lockout devices, tags, and accessories in one place. This organization helps workers quickly find and use the necessary tools, reducing downtime and enhancing compliance with safety protocols.

4. Circuit Breaker Lockouts

Specialized Electrical Safety

Electrical hazards are among the most dangerous in industrial environments. Circuit breaker lockouts are designed to isolate electrical circuits and prevent accidental reactivation. These devices are compatible with various types of circuit breakers and ensure that electrical panels remain securely locked out during maintenance.

5. Valve Lockouts

Comprehensive Isolation

Machinery often involves various types of valves that control the flow of liquids and gases. Valve lockouts are specifically designed to secure these valves in the off position, preventing the accidental release of hazardous substances. They come in different sizes and types to fit various valve handles, ensuring comprehensive coverage.

6. Padlocks and Tags

Clear Identification and Security

While padlocks are the cornerstone of any LOTO program, using high-quality, durable padlocks is essential. Safety House Loto offers a range of robust padlocks designed to withstand harsh industrial conditions. Additionally, tags provide critical information about the lockout procedure, including who is responsible and the reason for the lockout, enhancing communication and awareness.

Implementing a Comprehensive LOTO Program

Beyond Just Products

A successful LOTO program goes beyond just having the right products; it involves proper training and procedural adherence. Workers must be trained to understand the importance of lockout/tagout procedures and how to effectively use all LOTO accessories. Regular audits and updates to the LOTO program ensure it remains effective and compliant with regulatory standards.

Conclusion

Lockout Tagout products and accessories are essential components of an effective workplace safety program. As a leading manufacturer of lockout products, Safety House Loto provides a comprehensive range of devices and accessories that enhance the safety and efficiency of lockout/tagout procedures. From lockout hasps to valve lockouts, these accessories ensure that every aspect of energy isolation is covered, protecting workers from hazardous energy and preventing accidents. Implementing these tools and maintaining a robust LOTO program is crucial for any industrial operation committed to safety.

How Does Lockout Hasp Prevent You From Accidents?

Lockout hasps are designed to prevent you from accidents. Before we go into the details of how safety lockout products work to prevent accidents, let us understand the term.

When more than one employee is involved in a lockout:tagout operation, a lockout hasp plays an important role. As employees work in a group on the same energy source, the hasps allow multiple padlocks to be utilised when isolating one energy source. The lockout hasp is placed through a latch on the machinery. Each employee who is carrying out service or maintenance work attaches his padlock through any one of the six openings within the lockout hasp. All of the padlocks are then locked.

Lockout hasp has a zinc plated steel jaw so that they can pull at least 50 pounds. Sometimes, strong and spark resistant aluminium is also used in Jaws if required. Some are available with a nonconductive, red vinyl handle coating to improve the grip. It also protects the tool from scratching.

To maximise their use, Lockout Hasp also has the sign of “Danger” and “Do not Operate”. This can make them available to be used as a lockout device as well as a tag in one central unit. This ensures that each worker is working safely during the lockout operation. Various colour options in lockout hasps make them ideal for group lockout. Some lockout hasps are dual sided to lock out more than one of the equipment together.

How Lockout/Tagout Safety Can Prevent Accidents?

Working with machines requires great safety. Lockout Hasps can prevent accidents in the following way:

- Lockout Hasp does not let machines or equipment start unexpectedly. Machines may release stored energy or start by mistake which can cause harmful injuries. Safety lockout tagout products are of great use to prevent these situations.

- These lockout hasps provide efficient multi-person lockout. This means that Multiple padlocks can be applied to Loto Hasp, allowing an energy source to be isolated by more than one worker. This will ensure complete lockout and the machine can’t be operated until each worker unlocks their padlock from the hasp.

Although safety lockout products are mostly used in manufacturing companies, they can be also used in office buildings, healthcare facilities, construction sites, projects, hotels, ships, offshore installations, etc.

The good news is – it’s not an expensive proposition. Implementing an effective lockout/tagout program doesn’t require a heavy investment of time or money.

Safety House Is an ISO Certified company which manufactures products for Energy Isolation and you can trust their products for best safety.

Checkout our other safety products:

- Scaffold Tag

- Valve Lockout

- Key Box

Electrical Panel Lockout Switches With Safety

Electrical Panel as the name suggests are the systems which distribute the units of electricity to various electricity circuits due to which the other name is given to electrical panel that is distribution board. These panels are in robust in construction, rectangular in shape and vary in sizes according to the type of system which is to be imparted in the organization. When these Electrical panel lockout are not in use from the safety point of view lockout devices are used to avoid any miss happening to take place or any accident to occur which may lead to sudden death of any individual due to electrical shocks.

The Lockout devices that are very common now days and used in many industries for the purpose of safety are being described in the information stated below.

(1) MCB (Miniature Circuit Breaker) / Circuit Breaker Lockout Device very common lockout device, prevents the circuit breaker toggle from being turned on. It is then fit with an appropriate padlock to prevent unauthorized removal.

(2) Electrical Panel Lockout Device as the name suggest device with tough, lightweight, dielectric thermoplastic bodies that completely enclose the electrical plug thus protecting against accidental reconnection.

(3) Pendant Lockout device is used to lock large electrical connectors and control the hoist.

(4) Electrical Panel Lockout is used on switches where there is no inbuilt lockout provision. They consist of removable push button and rotary switch covers, which is secured with a padlock or hasp and this cover prohibits access to a switch or control on the electrical panel. They use transparent bases and cover that allow visibility of nameplates and labels.

(5) Panel Lockout is rectangular strip which is attached to the panel cover and the rectangular strip is encapsulated by the device preventing the panel cover from being removed. The circuit breakers remain locked off while work is being done. The Panel Lockout comes with a brass padlock and reusable tagout. Panel Lockout can also be used to prevent accidental shutdowns of critical equipment by keeping unauthorized persons from accessing electrical circuit breaker panels, security panels, and data centre panels and associated pull boxes.

(6) Electrical panel lockout with square base these are covering provided on the electrical button which is spring operated, these are used to avoid accidentally pressing the button.

The Lockout Tagout Products are a great way to ensure the workplace safety of the organizations as well as the individuals. There are many world pioneers in lockout/ tagout items and administrations that offer a wide scope of strong, simple to-utilize lockout gadgets that cover most mechanical and electrical applications. Many of them cover the other basic parts of an agreeable, viable vitality control program by giving imaginative answers for preparing workers, making reported methodology, and recognizing vitality sources. Many of these devices help various kinds of organizations with restricted assets rapidly get their program up to speed, guaranteeing that lockout exercises are executed in a way that advances ideal well-being while augmenting productivity and lessening downtime.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Hasp

Enquire Now

Safety House Loto Products For Safe Work Environment

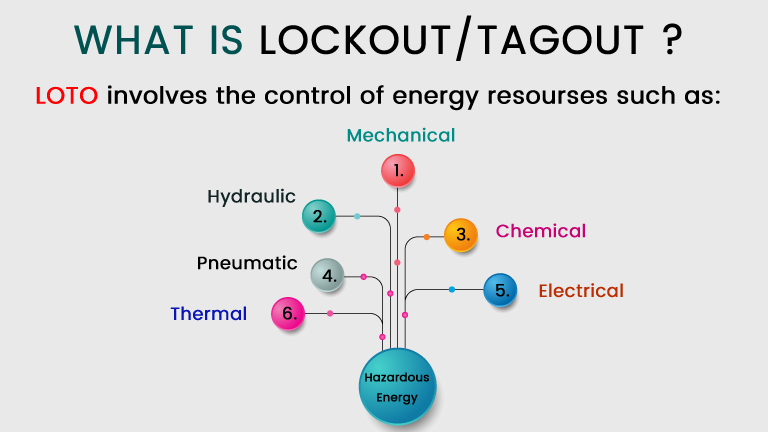

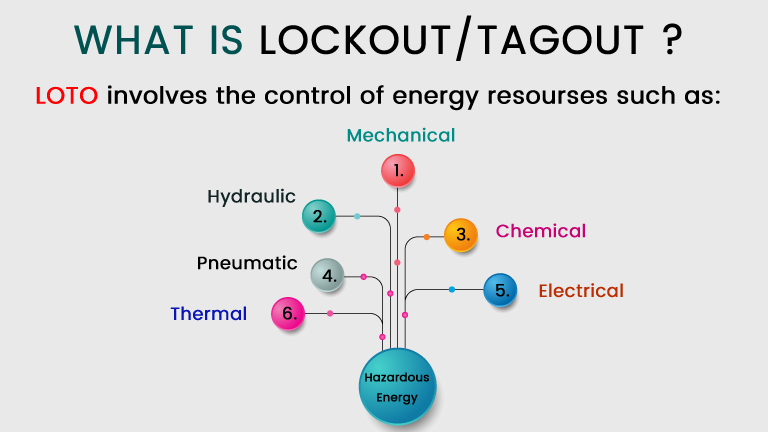

What is a Lockout/Tag out?

The logout/tag out is abbreviated as LOTO these are practices and procedures are now a days a very common practice which means shutting off the dangerous machines which contains hazardous waste like lubricating oils, smoke and degradable products which may harm the environment and not able to start them until and unless completion of maintenance or servicing work is done.Safety House Loto Products

While servicing is done hazardous energy is isolated and inoperative because if this hazardous waste is let free in the air might create a severe problem. After the service is done the service man hen locked and a tag is placed on the lock identifying the worker who has placed it which again states that this practice is a useful and safe practice for both the employee and environment as well. There are special devices designed and applied according to the nature of hazardous energy and nature of use which does not allow disposing of this hazardous waste into the open air. All these devices have the main motive of ensuring the workplace safety of all the individuals who are working under the organization.

There are various kinds tag out devices which can be used depending on the needs and interests of the hiring organizations and firms. Below stated are some different types of lockout devices with the name and nature of its use.

(1) Adjustable Ball valve locks are the most prominent devices used now a days in industry because they are easy to install and does not allow the easy disposed off the fluids nature of molecule as the application is the most simplest of all the tag out devices.

(2) Valve Lockouts are kind of caps which are placed on the rotating type valves, these are very easy to install and effective when in use.

(3) Safety Locks as the name suggest are the simple locks used at the storage areas where the hazardous waste is kept off to lock some operating rooms which are not in use of a room where the entry in only done when a person is able to fulfil the safety parameters as per required.

(4) Hubell Plugout used where the wires with plugs in front and the wires are not in use for some time. These are used to avoid the damage of the plug and as the material of the plug are plastic which may lead to damaging the environment as well.

(5) Circuit breaker lockout as the name suggest these are used where the electrical panel is installed and these helps in achieving operator safety.

Conclusion

There are many more which can be used but some of the basic tag out or lockout devices for the workplace safety are jotted down in the information stated above. Hence, we can conclude by remarking that the tag out devices can be used for the betterment of the environment of any organization as well as the proper safety of the employees working in that particular firm too.Safety House Loto Products

Checkout Our Other Lockout Tagout Products:

- Valve Lockout

- MCB Lockout

- Lockout Padlocks

Enquire Now

Why Valve Lockout Devices Are A Necessary Workplace Requirement

The safety and security of the workforce is important for any organization and it is their duty to ensure that the employees work in a hazard fee environment. The unexpected energization or startup of machines can pose some serious threat to the workers. Lockout Tagout Products provides protection that hold energy isolation devices in a safe position and prevents the release of hazardous energy and prevents machines or equipments from getting energized. In case machinery that the company employee is servicing or maintaining unexpectedly energizes, starts up, or releases stored energy then it can have very fatal consequences and injure the worker concerned.

Valve Lockout Devices For Workplace

Similarly valve lockouts prevent the occurrence of any harmful accidents during maintenance or repairs. With the help of Valve lockout devices workers can close off or isolate energy sources such as electricity and hydraulic pressure. By the statistical data compiled by OSHA (Occupational Safety and Health Administration) three million workers that majorly include electricians, machine operators, and laborers face this risk at work places. A victim can fracture their arms or legs, get burnt or electrocuted in the light of such an accident occurring. This is a serious issue on a personal level as the life and physical health of a laborer is concerned and also staff getting injured would gravely affect the productivity of an establishment.

Valve Lockout device is easy to use, safe and an inexpensive way to secure valves and prevent injury. They are used at workplaces to close off different kinds of pressured valves, these devices ensure that machineries that are value operated do not accidentally start working and remain switched during any maintenance work. The Valve Lockout Devices are attached over the operational part of the valve.

Safety House, the best manufacturer of lockout products In Delhi emphasis on taking prevention measures rather than waiting for accidents to happen. We also manufacture a wide range of the best Valve lock out Device.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Loto Kit

Enquire Now

Know More About Lockout Devices & Their Necessary Criteria

Many industrial accidents happen due to unexpected energisation of machines at workplace. To prevent such accidents from happening and to ensure a safe work environment for the employees, it is important for the organization to implement lockout devices. We at Safety House, the best manufacturer of Lockout Tagout Products in Delhi believe in being well prepared and fostering a culture of safety. There are certain criteria’s that Lockout Tagout Devices must meet before being used by any organization:

a) Lockout devices must be compatible with the work environment they are being used in. Tagout device warnings must remain legible even when they are used in wet, damp, or corrosive conditions.

b) Lockout and tagout devices must be designated by color, shape, or size and must have a standardized print and warning format.

c) The lockout and tagout devices must be really strong so that they can’t be removed inadvertently.

d) Tagout devices must be attached with a single-use, self-locking material such as a nylon cable tie.

e) Whichever employee sees the lockout or tagout device must be able to recognize who attached it and its purpose.

f) Each lock must have a unique key or a combination.

Safety House manufactures the best quality LOTO Products such as cylinder lockout, cable lockout and many more that meet the above necessary requirements.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Workplace Safety – The Introduction

Posted On: December 31, 2015

Categorized In: Safety / Security

Written By: Lockout India

Welcome to Lockout India. In this post which is our first, we will try and evaluate the basics of workplace safety, what we do & how we can help. The aspect of workplace safety we are talking about is the hazards caused by machines. A concept called “Energy Isolation” persists to verify the protocols. So what are the hazards? Who takes care of the procedure? What do we do? All your questions will be answered here. The hazard safety is an issue strictly limited to industries and factories. manufacturer of lockout products

What are the Hazards?

Hazards are provoked by energy. Since, all industrial machines require energy of some type (electrical, hydraulic, kinetic etc.), during service breaks and maintenance works; the machines need to be shut-off completely. However, machines running on power could start without warning (unexpectedly) or release the residual energy. Such instances could and have lead to fatal injuries and death of workers.

Some hazardous injuries are: Body fracture, Electrocution, Burns, Cutting, Crushing, Amputations etc. The fatality of the injury depends on the amount of pressure the machine dictates. This is to be avoided in any circumstance using the safety protocols.

The Safety Protocols

In an Ezine Article, we have given a sight into the Energy Isolation process. The safety procedure is known as LOTO procedure (Lockout- Tag out). OSHA also known as Occupational Safety & Health Administration is a prime organization of the United States Department of Labor whose aim is to ‘ensure a safe & healthy environment for workers enforced by certain standards. OSHA includes some definitions and gives out measures to be implemented during Energy Isolation.

Our Inclusion

Lockout India understands the importance of workplace safety and hence develops a wide range of products to fulfill that aim. All our Lockout Tagout products are CE certified that fit OSHA’s safety standards perfectly. Also, one other thing that has not been mentioned above is Tag out. Tag out means stamping a machine as closed. The “Warning” tag put up involves the person’s name, reason for tag and time. Also, some other types of tags are also included like ‘Danger’ tag, ‘do not start’ tag & ‘closed’ tag.

Our Products

Take a look at our extensive range of products. There are solutions for everything. There are group lockout boxes, hasps, valves, MCB lockouts, key cabinets, isolation padlocks, circuit breakers etc. Just scroll the pages or find your product with the advanced search option, add multiple products into the cart and get going with proofing your workplace.

Our aim apart from providing safety-insured products is “Customer Satisfaction”. By providing everything that the customer wants with his/her utmost satisfaction would make us proud. Stay tuned!

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now