Lockout Hasps for Small Businesses: Affordable Safety Solutions

The small business sector is faced with unique challenges in terms of safety for the employees. Due to the unavailability of funds, small teams, and diverse responsibilities, developing safety measures should be used as the base guidelines for hire affordableand efficient. In that sense, Safety House LOTO has been able to come to their rescue by supplying Lockout Hasps to ensure workplace safety in these very demanding, machinery and electric equipment-driven operational environments.

What Are Lockout Hasps?

Lockout Hasps are safety devices designed to lock out energy sources during equipment maintenance or repair. These devices allow multiple workers to secure a machine or electrical panel by attaching their personal padlocks to the hasp. This ensures that the equipment remains inoperative until all locks are removed, safeguarding workers from accidental startups or energy release.

Why Are Lockout Hasp Essential for Small Businesses?

Small businesses are often on tight budgets and cannot take risks with workplace accidents. Amy form of injury can lead to financial losses, legal liabilities, and downtime, which can really cripple the operation. Lockout Tagout (LOTO) products, including Lockout Hasps, are a worthwhile shield in that they are affordable and simple solutions to avoid any such catastrophe by locking out dangerous machinery or process.

1. Cost-Effective Safety

For small businesses, affordability is key. Lockout Hasp are relatively inexpensive compared to other safety measures. Their durable design and reusability make them a one-time investment with long-term benefits.

2. Versatility Across Industries

Whether you run a small manufacturing unit, a workshop, or a retail outlet with basic electrical systems, Lockout Hasp can be adapted to various equipment types. They are particularly useful for machines with multiple energy sources, where multiple workers need to secure the system.

3. Compliance with Safety Regulations

Adhering to workplace safety regulations is essential for businesses of all sizes. LOTO systems, including Lockout Hasp, help small businesses comply with Occupational Safety and Health Administration (OSHA) guidelines or similar regulatory requirements, reducing the risk of penalties.

How Lockout Hasps Work

The simplicity of Lockout Hasps is one of their strongest features. Here’s how they function:

- Placement: The hasp is placed through the energy isolation point, such as a switch or valve.

- Locking: Each worker involved in the maintenance attaches their personal lock to the hasp.

- Team Safety: The machine cannot be reactivated until every lock is removed, ensuring collective safety.

This collaborative approach to safety is particularly beneficial in workplaces with multiple employees handling the same equipment.

Types of Lockout Hasps

Small businesses can choose from a range of Lockout Hasps to suit their specific needs:

1. Standard Lockout Hasp

These are basic hasps made of durable materials, suitable for general-purpose use.

2. Insulated Lockout Hasp

Ideal for electrical applications, these hasps are coated with non-conductive materials to enhance worker safety.

3. Heavy-Duty Lockout Hasp

For machinery with high energy levels or challenging environments, heavy-duty hasps provide added durability and reliability.

Benefits of Using Lockout Hasps

1. Enhanced Worker Safety

By preventing unauthorized access to equipment, Lockout Hasps reduce the risk of accidents caused by unexpected startups.

2. Promotes Accountability

Each worker uses their lock, ensuring personal responsibility for safety during maintenance.

3. Simplified Processes

The ease of use makes Lockout Hasp accessible for small businesses, even with limited training resources.

4. Long-Term Durability

Built to withstand tough conditions, Lockout Hasps offer long-lasting protection, making them a cost-effective choice for safety.

Integrating Lockout Hasps with Lockout Tagout Products

While Lockout Hasps are critical, their effectiveness is amplified when integrated into a comprehensive Lockout Tagout system. Other essential LOTO products include:

- Padlocks: Used in conjunction with hasps to secure energy sources.

- Tags: Provide clear communication about the locked-out equipment, including who locked it and why.

- Valve and Circuit Breaker Locks: Specialized devices for isolating specific types of energy sources.

Small businesses can create a robust safety framework by combining these products, ensuring a safer workplace.

Choosing the Right Lockout Hasps for Your Business

When selecting Lockout Hasps, small businesses should consider:

- Material: Opt for durable materials like steel or non-conductive coatings, depending on the application.

- Size and Design: Ensure compatibility with your equipment’s energy isolation points.

- Ease of Use: Choose hasps that are simple to implement, especially if your team is new to LOTO practices.

Conclusion

To small businesses, safety does not mean spending a lot. Lockout Hasps provide an effective and affordable answer to workplace accidents and safety regulations compliance. Their affordability, versatility, and durability make them an indispensable item you may find in any Lockout Tagout system.

Quality LOTO products protect employees while cutting down on downtime, allowing a culture of safety to develop in businesses. Be they small workshops or a small enterprise that is looking to develop, the inclusion of the Lockout Hasps will serve as a forward step towards a safe and high-performing workplace.

How Does Lockout Hasp Prevent You From Accidents?

Lockout hasps are designed to prevent you from accidents. Before we go into the details of how safety lockout products work to prevent accidents, let us understand the term.

When more than one employee is involved in a lockout:tagout operation, a lockout hasp plays an important role. As employees work in a group on the same energy source, the hasps allow multiple padlocks to be utilised when isolating one energy source. The lockout hasp is placed through a latch on the machinery. Each employee who is carrying out service or maintenance work attaches his padlock through any one of the six openings within the lockout hasp. All of the padlocks are then locked.

Lockout hasp has a zinc plated steel jaw so that they can pull at least 50 pounds. Sometimes, strong and spark resistant aluminium is also used in Jaws if required. Some are available with a nonconductive, red vinyl handle coating to improve the grip. It also protects the tool from scratching.

To maximise their use, Lockout Hasp also has the sign of “Danger” and “Do not Operate”. This can make them available to be used as a lockout device as well as a tag in one central unit. This ensures that each worker is working safely during the lockout operation. Various colour options in lockout hasps make them ideal for group lockout. Some lockout hasps are dual sided to lock out more than one of the equipment together.

How Lockout/Tagout Safety Can Prevent Accidents?

Working with machines requires great safety. Lockout Hasps can prevent accidents in the following way:

- Lockout Hasp does not let machines or equipment start unexpectedly. Machines may release stored energy or start by mistake which can cause harmful injuries. Safety lockout tagout products are of great use to prevent these situations.

- These lockout hasps provide efficient multi-person lockout. This means that Multiple padlocks can be applied to Loto Hasp, allowing an energy source to be isolated by more than one worker. This will ensure complete lockout and the machine can’t be operated until each worker unlocks their padlock from the hasp.

Although safety lockout products are mostly used in manufacturing companies, they can be also used in office buildings, healthcare facilities, construction sites, projects, hotels, ships, offshore installations, etc.

The good news is – it’s not an expensive proposition. Implementing an effective lockout/tagout program doesn’t require a heavy investment of time or money.

Safety House Is an ISO Certified company which manufactures products for Energy Isolation and you can trust their products for best safety.

Checkout our other safety products:

- Scaffold Tag

- Valve Lockout

- Key Box

Common Yet Useful Lockout Devices

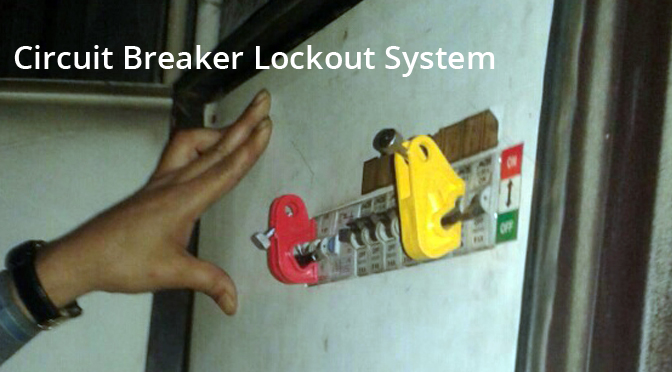

1. Circuit Breaker Lockout Devices: These are automatic electrical switches that are designed to protect circuit boards from overload or short circuit. At Lockout India, circuit breakers are designed to work on most varieties of breakers including single-pole and multi-pole breaker specifications.

These are used to isolate a given breaker in a panel so there’s no further need to lockout the entire breaker. Molded from durable plastics, their basic task however is to detect faulty conditions and automatically open the circuit.

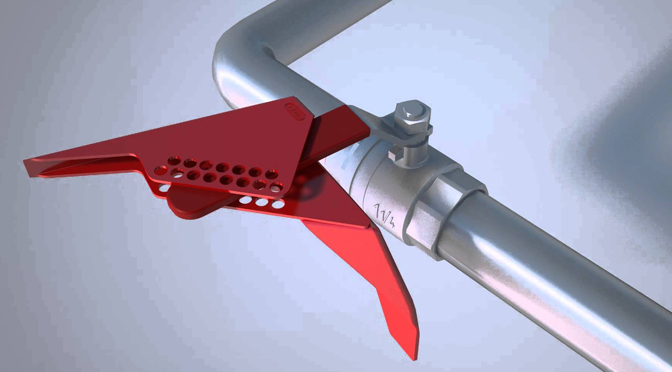

2. Valve and Pneumatic Lockout Devices: Just like electricity, gases and fluids can be significantly hazardous. They tend to move at tremendous pressures and can severely injure if released inappropriately. Valve lockout devices are designed to isolate such hydraulic energy sources. There are different types of available valves such as ball valves, butterfly valves, gate valves, and pneumatic disconnects.

3. Plug Lockout Devices: Portable cords and connected plugs are a common site in work facilities. However, it is important to isolate such electrical sources into a socket using a power plug if one needs to comply with OSHA’s standards.

Our secure design locks onto prongs to prevent them from getting inserted into wall outlets. It can be used with your existing lockout hasps and padlocks.

4. Cable Lockout Devices: This device secures, holds, and locks out electrical power handles and gate valves. Cable lockout devices are conveniently isolated energy and are easy to use. They further ensure successful lockout across multiple energy sources and stop the workforce from actualizing devices while the maintenance is being carried out.

5. Lockout Hasp: Hasp lockout devices are an integral part of a successful safety program. They provide multi-person lockout and multiple padlocks can be applied hasps, allowing the energy to be isolated by more than one worker at a time.

Energy cannot be worked upon until each worker unlocks the padlock. Our wide range of hasps includes dielectric hasps, dual jaw hasps, electroplated hasps, labeled hasps, premier lockout hasps, and non-conductive hasps.

When are these devices used?

– While machinery is being serviced or maintained

– While installing new equipments and machineries

– When a safety device needs to be bypassed or removed

– Moving machineries and equipments

– Any machinery prone to unexpected start-up

Most importantly, whenever a lockout safety device is applied to a machinery, it must remain under exclusive observation and shouldn’t be removed by any unauthorized personnel. manufacturer of lockout products

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Also read: How to Use Electrical Lockout Devices and Equipment?

Also read: Types of Lockout Tags & Its Usage for Industrial Safety

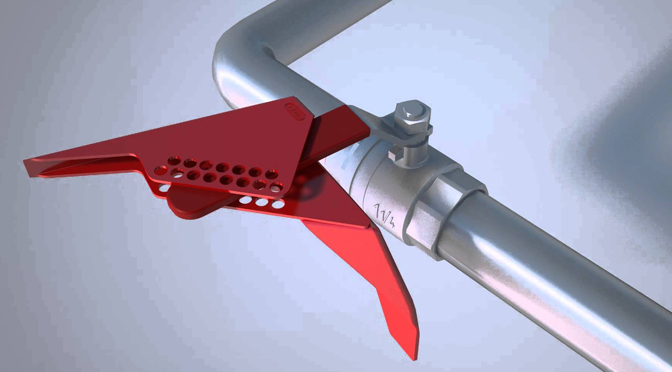

All About Ball Valve Lockout Devices

A work facility is an inexhaustible source of hazardous energy. Energy sources include electrical, hydraulic, mechanical, pneumatic, thermal, etc. and can be detrimental to work forces within the premises. A lot of industrial mishappenings around the world are caused by unexpected energy release and unanticipated equipment startup.ball valve lockout devices

A lockout safety method locks out such energy-isolating devices and ensures that they cannot be operated until the lockout device is removed. It simply aims at improving safety, maintaining compliance and encouraging sustainability. However daunting it might seem, it’s imperative that all the layers of the organization work towards implementing a sustainable lockout safety program. Without seamless cooperation, a lockout system would fall apart.

Of all the safety Lockout Tagout Products, today, we’ll discuss about Ball Valve Lockout. Ball Valve is a quarter-turn, straight-through valve that suitably transfers liquids, compressed air, clean gas and slurries (liquids with suspended solids). It uses a hollow and perforated ball to control the flow through it. The ease of operation, repair and versatility that comes with ball valves is what leads to its extensive industrial use. Ball valves have a round closure element that permits consonant sealing stress. Getting its name from the ball that rotates within to close and open the valve, these devices are used where a taut shut-off is required and are a fine source for control applications. Durable and reliable even after jagged use, these safety devices are often preferred to gate and globe valves. Ball valves involve the use of materials such as nylon, delrin, synthetic rubbers and polymers and that imparts an excellent sealing ability. However, there is a potential of wear on the seats and it renders it unsuitable for throttle applications.

Types of Ball Valves:

Valve operation in each type remains the same. The only difference is how these valves are manufactured and assembled. Each design has its own benefits.

– Split body Ball Valve

– Top entry Ball Valve

– End entry Ball Valve

– Double trunnion Ball Valve

– 3-piece Ball Valve

– Lubricated/Non-lubricated Ball Valve

Advantages that a ball valve renders:

– Smooth and straightforward actuation

– Swift opening and closing

– More compact and lighter than a gate valve

– Bubble-tight service

– Wide choices, thus allowing flexibility

– Multi-port designs

– Reliable in high-temperature and high-pressure applications

Used in a variety of applications such as gas processing and storage, fire safe protection services, chlorine manufacturing, and flowing systems, ball valves. Some typical applications are:

– Low point drains in fluid services

– High-point vents in fluid services

– Instrument root valves

– Steam service

– Feed water systems

At Lockout India, it’s all about committing to quality, performance and service. We are the leading manufacturer of various types of Ball Valve Lockout devices and our products satiate different industrial requirements and convincingly control the flow of diverse gases and fluids.

Checkout Our Other Lockout Tagout Products:

- Lockout Kit

- Group Lockout Box

- Lockout Station

Enquire Now

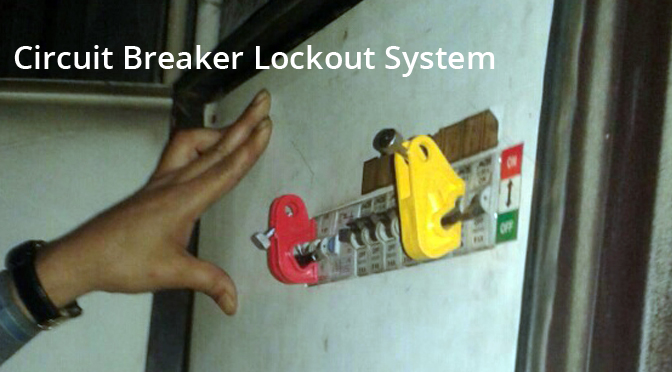

Circuit Breaker Lockout System

You must have observed MCB’s (Miniature Circuit Breaker) installed in your house. When you switch on or shut-down the appliance, the electricity of an entire floor gets affected. This is because all the circuits in the floor are connected with the MCB Lockout and by turning off the main switch, the lights go out. However, this is not the prime task of a circuit breaker but to protect the appliance and the people from potential electrical shocks and faults. In other words, Circuit Breakers are the appliances that blocks possible electrical short-circuits and helps maintain the flow of electricity.

A lot of people fail to comprehend the reason as to how Circuit Breakers come under the OSHA guidelines. As per OSHA’s standard 29 CFR 1910.147, all the devices that are dangerous and can cause accidents must be disconnected from all kinds of appliances, including Circuit Breakers so that the machines can’t operate itself in absence of workers. And since Circuit Breakers are basically like a switch with on/off system, it’s required to count them in Lockout-Tagout procedure.

Circuit breakers lockout system involves locking out the switches of the circuits through circuit breaker lockout equipment. The kit includes yellow rail assembly, 2 x 1-way pins, 1 x 2-way pins, 1 x cup pin, pin holder, and self tapping screws which come specifically designed for each panel. The process of killing the switches is very easy through the Lockout Kit.

There are numerous lockout-tagout service providers in the country. However, not all of them deliver quality products to their customers. ‘Safety House’ is a trusted company that has been in business since a considerable amount of time and has hundreds of satisfied clients. So make sure to choose the best LOTO service provider for your establishment which meets your requirements.

Checkout Our Other Lockout Tagout Products:

- Lockout hasp

- Group Lockout Box

- Lockout Station

- Valve Lockout

Enquire Now

Learn About Safety House’s Mini Lockout Station

Safety House – LOTO is the best manufacturer of manufacturer of lockout products in Delhi & NCR regions. Providing lockout tagout products such as ACB lockout, MCB lockout and lockout tagout station cabinet, its devices are in accordance to OSHA standards.

Today, let us talk about our Mini Lockout Station.

1. To start with, a mini lockout station is placed next to a machine isolator and other lockout points. This is so that lockout tagout equipment is easily accessible when required.

2. Ours has an ‘open box type pocket’ for small materials, such as tag holders.

3. It is wall hanging type, which means it can be mounted on any surface.

4. The additional hooks at the bottom of the station let you hang locks or hasps.

5. It helps the user mix-match with existing equipment.

Like all our loto Kit, it can be made as per client requirement, on terms. Pockets and slotters can be customized. Our aim is customer satisfaction in all respects. We achieve this by providing CE-certified products, and being uncompromising in terms of quality.

Our equipment can be used by various organisations, including, manufacturing units/ factories, processing plants, construction sites, ships, offices and so on.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Five Most Cited Serious Violations As Per OSHA – II

Scaffolding: OSHA asks every scaffold and scaffold component to be able to support without any failure not just its own weight, but at least four times the maximum load intended to apply to it. There are of course exceptions to this rule, such as suspension ropes, used on suspension scaffolds that are non-adjustable. These should be capable of supporting at least six times the maximum weight intended to be transmitted to it.

Respiratory Protection: OSHA asks for preventing atmospheric contamination, so that occupational respiratory diseases are not caused by inhaling any harmful vapor, spray, smoke, gas, mist, fume, fog and dust. This is to be achieved by using materials that are less topic, conducting operations in an enclosed area, ventilation and other engineering control measures. If such measures are not feasible, respirators are to be provided to the workers.

Lockout Tagout: Appropriate LOTO devices must be used to prevent unexpected energization/ release of stored energy from machines.Equipment must be tested to verify the effectiveness of lockout tagout products and other energy control measures. The employer is to provide training so that the function of the energy control program is understood by the workers. This section covers the servicing of machines and equipment.

As the top manufacturer of LOTO devices, Safety House provides products like lockout tagout kit and key cabinet at reasonable prices.

To Continue Click Here

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Five Most Cited Serious Violations As Per OSHA – I

Readers of the blog of New Delhi, India-based manufacturer of Lockout products, ‘Safety House’ would know that our wide range of products is as per OSHA. In the last bog post, we gave you an insight into top violations as cited by the federal agency of the United States Department of Labor. Today, we discuss five serious violations in detail. (For those unaware, OSHA releases a list of top serious violations every year.)

Fall Protection: Employers must provide fall protection systems. Like all other points, this is vast, but employees need to determine if walking surfaces have the strength to support employees. Walking surfaces that are over 6 feet above a lower level must be protected through guardrail/ safety net/ personal fall arrest systems. Same goes for every worker constructing a leading edge 6 feet or more above a lower level. The only exception to this rule is when an employer can ‘demonstrate’ that using these systems, on the contrary, poses greater harm. The employer in this case would be required to develop an alternate fall protection system.

Hazard Communication: This is concerned with chemical safety at workplaces. Of prime importance is the fact that hazards by chemicals must be identified, and available to/ understood by workers. Signs and right-to-know placards should be used. The requirements of the hazard communication section by OSHA are consistent with UN’s GHS, i.e. Globally Harmonized System of Classification and Labelling of Chemicals. lockout supplier

To Continue Click Here

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Lockout Tagout And OSHA

Posted On: February 3, 2016

Categorized In: Lockout/Tagout

Written By: Lockout India

At Safety House (LOTO), we adhere to OSHA (Occupational Safety and Health Administration) guidelines while manufacturing lockout tagout/ workplace area safety/ site management products. Our range of products includes key cabinet, This blogpost would give you an insight into what OSHA is, and why following it is imperative for the safety of your employees. lockout supplier

The main federal agency of the US Department of Labor, OSHA was established in 1971 by the Congress under the Occupational Safety and Health Act. The mission of the agency is to “assure safe and healthful working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education and assistance”.

OSHA’s health and safety standards are aimed at preventing accidents and accidental use of energy. The federal agency enforces the development, documentation, implementation, and enforcement of energy control procedures. It recommends that only lockout/ tagout devices authorized for a particular machinery or equipment are used, and that these devices are durable, standardized and substantial. It also asks to ensure that lockout tagout devices identify individual users. OSHA further recommends the establishment of a policy that permits only the employee who applied a LOTO device to remove it. Energy control procedures need to be inspected at least annually. Furthermore, effective training is to be provided for all employees.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Lockout Procedures to Follow

Posted On: January 19, 2016

Categorized In: Lockout/Tagout

Written By: Lockout India

Lockout means shutting out machines. An industrial machine shuts for maintenance and servicing activities. It is carried out as a safety measure. The maintenance workers might injure themselves by their sudden startup. There is a certain lockout procedure implemented during the whole process. This process is undertaken by following every known guideline as given by OSHA.

As Lockout India creates safety equipment for such processes, we believe that you, our beloved readers should have an idea of the procedures followed during the process. Please note that the steps we are about to mention are general guidelines or sample steps. In reality, something very close to them is followed because admit it, “field work is much different”.

We need to understand 3 main criteria’s while learning the procedure.

- System – refers to the machines/equipment

- Authorized Employee – refers to the expert who carries out the full procedure

- Affected Employee – includes the workers, various staff members etc. who aren’t qualified to carry out the process

Lockout Procedures

Shutdown

1. The first step is to turn off all the energy sources from the operator’s panel. However, the authorized employee has to make sure that none of the affected employees are still operating as sudden power loss could lead to major accidents.

2. After power shut, notifying the affected employees is the next step. They are to leave their stations immediately and await further instructions.

3. The third step now is to shut down the whole system using normal stopping procedures like powering down, stoppers etc.

Lockout/Tag out

1. Firstly, isolate the system from any energy source. This process is called energy isolation.

2. Lockout and Tag out the system with appropriate safety products.

3. Release any stored energy from the springs, capacitors, hydraulics etc. This is very important as the residual energy in these parts could release automatically during maintenance and harm the crew.

4. Confirm that isolation has actually taken place by trying the equipment.

5. If system doesn’t start means it’s in lockdown mode.

Maintenance

Let the crew carry out maintenance and servicing.

In the meantime, continue your verifications through inspections, observations and tests.

Restarting the System

- After maintenance, remove all the locks and tags.

- Clear out all personnel and unnecessary items from the area.

- The main system shall be then restarted.

- Check whether all machines are working as they should.

- Finally, notify all the employees to resume their work.

One main thing to be kept in mind is that sometimes the work scale is too big meaning multiple authorized employees are involved. However, the procedure is more-or-less ‘the same’. It is unfortunate to say that despite several listed Lockout Tag out procedures, every year thousands of work infringements take place due to non-compliance of appropriate protocols. We, thereby urge all those who are reading this and work in the industry to go through the guidelines provided by OSHA in detail. In case you need further help regarding Lockout Tag out and safety-insured products, ping us!

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now