Know More About Lockout Devices & Their Necessary Criteria

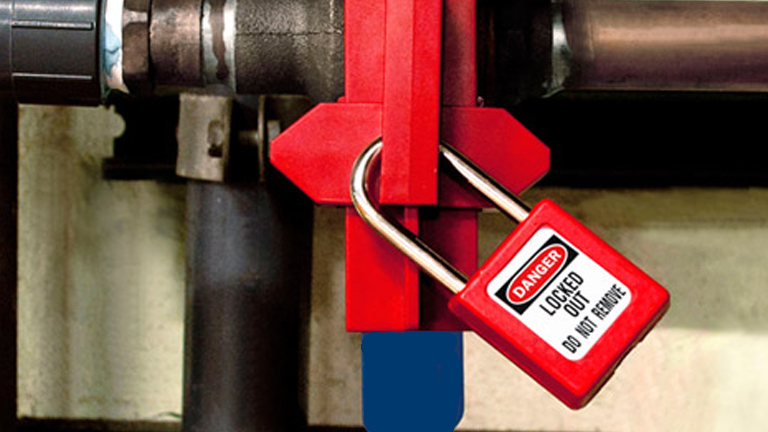

Many industrial accidents happen due to unexpected energisation of machines at workplace. To prevent such accidents from happening and to ensure a safe work environment for the employees, it is important for the organization to implement lockout devices. We at Safety House, the best manufacturer of Lockout Tagout Products in Delhi believe in being well prepared and fostering a culture of safety. There are certain criteria’s that Lockout Tagout Devices must meet before being used by any organization:

a) Lockout devices must be compatible with the work environment they are being used in. Tagout device warnings must remain legible even when they are used in wet, damp, or corrosive conditions.

b) Lockout and tagout devices must be designated by color, shape, or size and must have a standardized print and warning format.

c) The lockout and tagout devices must be really strong so that they can’t be removed inadvertently.

d) Tagout devices must be attached with a single-use, self-locking material such as a nylon cable tie.

e) Whichever employee sees the lockout or tagout device must be able to recognize who attached it and its purpose.

f) Each lock must have a unique key or a combination.

Safety House manufactures the best quality LOTO Products such as cylinder lockout, cable lockout and many more that meet the above necessary requirements.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Checklist For Better Use of Lockout/Tagout Program

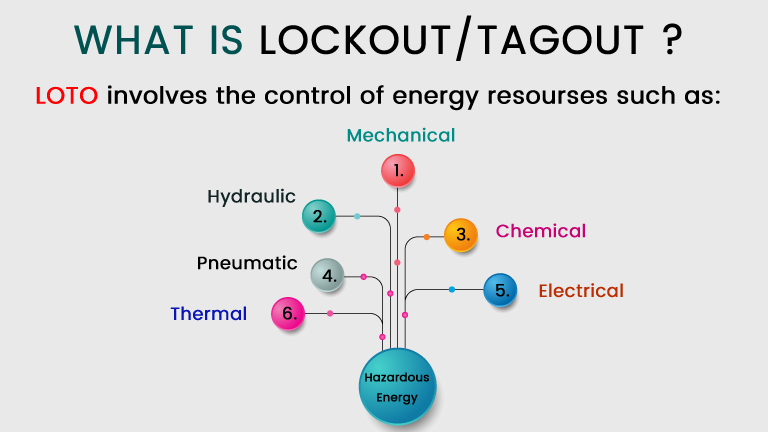

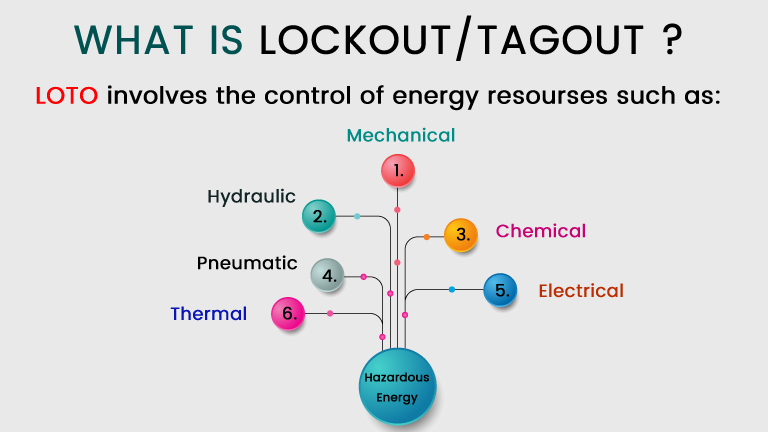

Lockout/ Tagout acceptance in your workplace is an essential safety requirement. Preventing the unpredictable accidents of dangerous gasses or energies during service and maintenance ensures the safety of workers and helps to build a productive work environment. Lockout Tagout Products require proper adoption and implementation for workplace and employees. According to a report of Occupational Safety and Health Administration (OSHA), around three million people working with big equipment or machines face the risk of injuries if lockout/ tagout (LOTO) is not properly implemented. This blog post will provide few tips to help your company stay disciplined.

Choose The Right Device: The lockout padlock is one of the important parts of LOTO family. Valves, circuit breakers, switches, etc. are just some of the machines that require lockouts. Sometimes purchasing the right type of lockout may seem overwhelming as these products come in many variants.

Before buying a padlock for your workplace, few things are going to help you a lot:

1. Knowing the exactly right product and use devices verified as per OSHA standard.

2. Make a list of machines that may need lockout devices.

3. Always use standardized goods and tools to keep devices organized.

Lockout Station is an effective way to hold critical devices. This product not only stores important devices, but also they save space, time and efficient operations.

Complete Document Strategy: Lockout implementation needs to be documented by process. This process will help to remove any possible confusion about the ability of management and workers. Documentation also provides employees with valuable training tips. Fixed documentation provided by OSHA is required, given the differences in workplaces and machines, not every Lockout procedure will be the same. It Is very important to make sure the systems are as efficient as possible.

Establish An Attentive Training Program: Careful and thorough training is an essential part of a successful lockout program. All workplaces need to be trained according to their need. It is imperative for each and every worker to his role. Work should be explicitly assigned and defined to the appropriate employee. Strong communication is required to develop among all employees so that they clearly alert affected employees when a lockout device is being placed and removed. Every padlock has a space to write worker’s name.

Careful Evaluation: A careful evolution is a crucial for development. Lockout training and written procedures can be counted as a success, only if they are used in actual maintenance situations. Analysis is important to make sure that the training exercises, procedure, and devices are working properly.

Take a look at LOTO products at www.lockoutindia.com and decide if the products shown on the website will meet all your criteria necessary protect employees while working.

Checkout Our Other Lockout Tagout Products:

- Lockout Hasp

- Group Lockout Box

- Lockout Padlocks

- Valve Lockout

Enquire Now

Five Most Cited Serious Violations As Per OSHA – II

Scaffolding: OSHA asks every scaffold and scaffold component to be able to support without any failure not just its own weight, but at least four times the maximum load intended to apply to it. There are of course exceptions to this rule, such as suspension ropes, used on suspension scaffolds that are non-adjustable. These should be capable of supporting at least six times the maximum weight intended to be transmitted to it.

Respiratory Protection: OSHA asks for preventing atmospheric contamination, so that occupational respiratory diseases are not caused by inhaling any harmful vapor, spray, smoke, gas, mist, fume, fog and dust. This is to be achieved by using materials that are less topic, conducting operations in an enclosed area, ventilation and other engineering control measures. If such measures are not feasible, respirators are to be provided to the workers.

Lockout Tagout: Appropriate LOTO devices must be used to prevent unexpected energization/ release of stored energy from machines.Equipment must be tested to verify the effectiveness of lockout tagout products and other energy control measures. The employer is to provide training so that the function of the energy control program is understood by the workers. This section covers the servicing of machines and equipment.

As the top manufacturer of LOTO devices, Safety House provides products like lockout tagout kit and key cabinet at reasonable prices.

To Continue Click Here

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Five Most Cited Serious Violations As Per OSHA – I

Readers of the blog of New Delhi, India-based manufacturer of Lockout products, ‘Safety House’ would know that our wide range of products is as per OSHA. In the last bog post, we gave you an insight into top violations as cited by the federal agency of the United States Department of Labor. Today, we discuss five serious violations in detail. (For those unaware, OSHA releases a list of top serious violations every year.)

Fall Protection: Employers must provide fall protection systems. Like all other points, this is vast, but employees need to determine if walking surfaces have the strength to support employees. Walking surfaces that are over 6 feet above a lower level must be protected through guardrail/ safety net/ personal fall arrest systems. Same goes for every worker constructing a leading edge 6 feet or more above a lower level. The only exception to this rule is when an employer can ‘demonstrate’ that using these systems, on the contrary, poses greater harm. The employer in this case would be required to develop an alternate fall protection system.

Hazard Communication: This is concerned with chemical safety at workplaces. Of prime importance is the fact that hazards by chemicals must be identified, and available to/ understood by workers. Signs and right-to-know placards should be used. The requirements of the hazard communication section by OSHA are consistent with UN’s GHS, i.e. Globally Harmonized System of Classification and Labelling of Chemicals. lockout supplier

To Continue Click Here

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

3 Common LOTO Safety Range Of Products

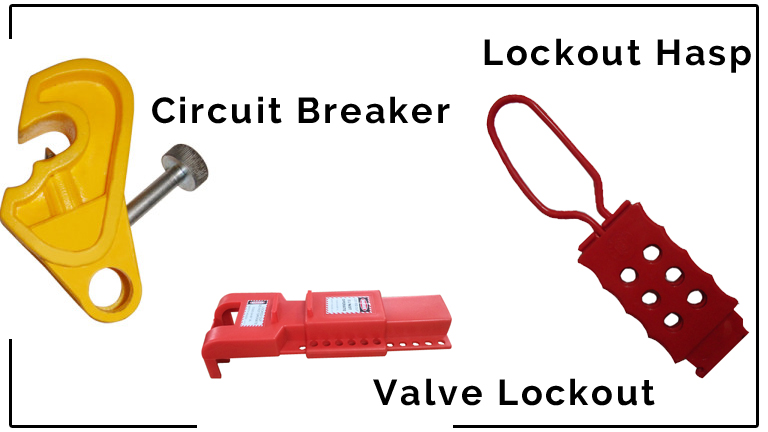

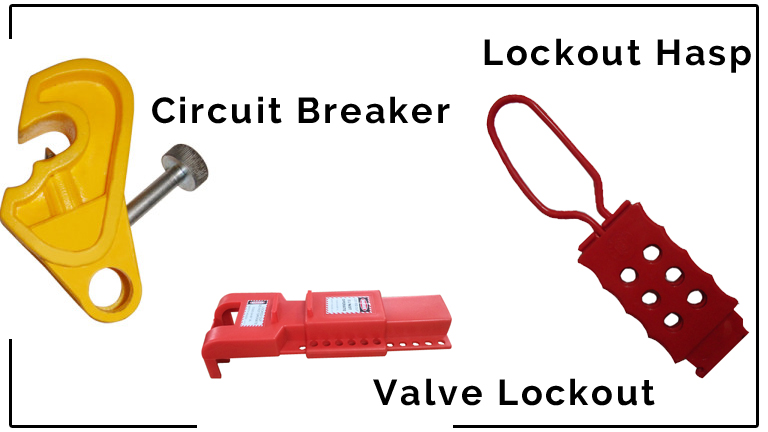

Hasps – At ‘Safety House – LOTO’, the best manufacturer of lockout products in India, the product range of hasps includes dielectric hasp, double jaw hasp/ dual jaw hasp and electroplated hasp. But what is a hasp? And what do they do? More than one worker often performs repair/ maintenance on a piece of equipment. Ideal for group lockout procedures, a hasp lets more than one worker to put padlock and lockout an energy source. It ensures that they remain safe. lockout supplier

Circuit Breaker Lockout – Our website ‘Lockout India’ lists an impressive range these LOTO devices that are used to isolate a particular breaker in a circuit breaker panel. Have a look at our Circuit Breaker Lockout page to see our large circuit breaker lockout, MCB lockout, MCB pin lockout, mini circuit breaker lockout and more. These lockout the breakers of all major brands. Once a breaker has been isolated, the whole breaker box doesn’t require locking out.

Valve Lockout – Valve lockouts are used for shutting off gas or fluid valves. Preventing these valves, including ball valve (Commonly used handles that are turned at 90° to shut off.), cylinder valve, butterfly valve and gate valve (These are round knobs.), from opening is important, when repair work/ maintenance is being performed. While gate valve lockouts are measured by their diameter, ball valve lockouts are determined by the handle length. You may also like to have a look at our butterfly valve lockout.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Lockout Tagout And OSHA

Posted On: February 3, 2016

Categorized In: Lockout/Tagout

Written By: Lockout India

At Safety House (LOTO), we adhere to OSHA (Occupational Safety and Health Administration) guidelines while manufacturing lockout tagout/ workplace area safety/ site management products. Our range of products includes key cabinet, This blogpost would give you an insight into what OSHA is, and why following it is imperative for the safety of your employees. lockout supplier

The main federal agency of the US Department of Labor, OSHA was established in 1971 by the Congress under the Occupational Safety and Health Act. The mission of the agency is to “assure safe and healthful working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education and assistance”.

OSHA’s health and safety standards are aimed at preventing accidents and accidental use of energy. The federal agency enforces the development, documentation, implementation, and enforcement of energy control procedures. It recommends that only lockout/ tagout devices authorized for a particular machinery or equipment are used, and that these devices are durable, standardized and substantial. It also asks to ensure that lockout tagout devices identify individual users. OSHA further recommends the establishment of a policy that permits only the employee who applied a LOTO device to remove it. Energy control procedures need to be inspected at least annually. Furthermore, effective training is to be provided for all employees.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Lockout Procedures to Follow

Posted On: January 19, 2016

Categorized In: Lockout/Tagout

Written By: Lockout India

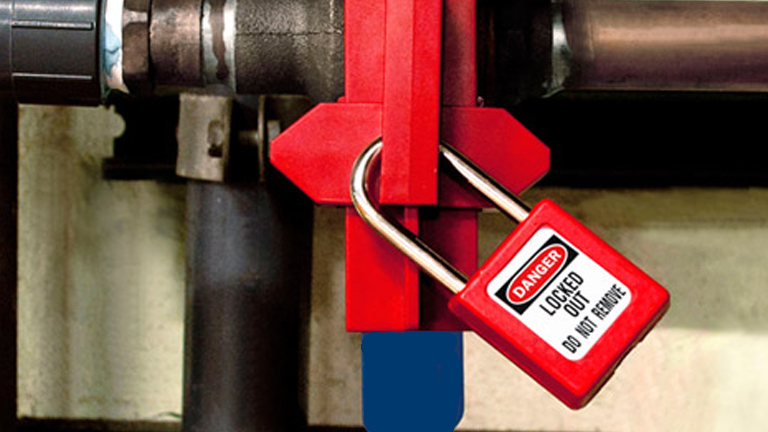

Lockout means shutting out machines. An industrial machine shuts for maintenance and servicing activities. It is carried out as a safety measure. The maintenance workers might injure themselves by their sudden startup. There is a certain lockout procedure implemented during the whole process. This process is undertaken by following every known guideline as given by OSHA.

As Lockout India creates safety equipment for such processes, we believe that you, our beloved readers should have an idea of the procedures followed during the process. Please note that the steps we are about to mention are general guidelines or sample steps. In reality, something very close to them is followed because admit it, “field work is much different”.

We need to understand 3 main criteria’s while learning the procedure.

- System – refers to the machines/equipment

- Authorized Employee – refers to the expert who carries out the full procedure

- Affected Employee – includes the workers, various staff members etc. who aren’t qualified to carry out the process

Lockout Procedures

Shutdown

1. The first step is to turn off all the energy sources from the operator’s panel. However, the authorized employee has to make sure that none of the affected employees are still operating as sudden power loss could lead to major accidents.

2. After power shut, notifying the affected employees is the next step. They are to leave their stations immediately and await further instructions.

3. The third step now is to shut down the whole system using normal stopping procedures like powering down, stoppers etc.

Lockout/Tag out

1. Firstly, isolate the system from any energy source. This process is called energy isolation.

2. Lockout and Tag out the system with appropriate safety products.

3. Release any stored energy from the springs, capacitors, hydraulics etc. This is very important as the residual energy in these parts could release automatically during maintenance and harm the crew.

4. Confirm that isolation has actually taken place by trying the equipment.

5. If system doesn’t start means it’s in lockdown mode.

Maintenance

Let the crew carry out maintenance and servicing.

In the meantime, continue your verifications through inspections, observations and tests.

Restarting the System

- After maintenance, remove all the locks and tags.

- Clear out all personnel and unnecessary items from the area.

- The main system shall be then restarted.

- Check whether all machines are working as they should.

- Finally, notify all the employees to resume their work.

One main thing to be kept in mind is that sometimes the work scale is too big meaning multiple authorized employees are involved. However, the procedure is more-or-less ‘the same’. It is unfortunate to say that despite several listed Lockout Tag out procedures, every year thousands of work infringements take place due to non-compliance of appropriate protocols. We, thereby urge all those who are reading this and work in the industry to go through the guidelines provided by OSHA in detail. In case you need further help regarding Lockout Tag out and safety-insured products, ping us!

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now