How to Use Electrical Lockout Devices and Equipments?

When utilized in industrial high voltage or low voltage applications, electrical lockout devices may help prevent electrical accidents by ensuring that electrical systems are properly shut off. One of the most common methods of preventing accidental or unintentional access to electrical power sources is implementing a Lockout-Tagout technique (LOTO).

Using this secure process, every person working on the same circuit or piece of equipment has a lock that they fasten to a disconnect device before starting their job.

Lockout operations are complete when the disconnect switch or isolation device is free of all locks and lockout devices, indicating that the last worker has granted permission for the line to be re-energized after the lockout operation has been completed.

Procedure to Use the Electrical Lockout Tagout Devices

A normal lockout Tagout method calls for locating all possible power sources. A qualified worker must properly inform on the scope of the operation before they shut down the line or circuit. The following are some of the methods on how to use Electrical Lockout Devices and Equipment.

Locate the process that will follow

Binders or lockout Tagout software may use in your organization. First, locate the steps to use electrical lockout devices necessary for the machine you will be working on and follow them to completion.

According to the manufacturer’s recommendations, this technique should describe the step-by-step approach for shutting down and restarting the equipment. Read More: What Are The Usage Of Electrical Plug Lockouts?

Notify any concerned persons

Any work on the equipment must complete only after all co-workers, contractors, and other parties who may inform of the project’s progress. In addition, if any adjustments need to be made to work procedures, make sure that everyone is informed of these changes.

Find all energy sources

The Lockout Tagout technique you are using should include all of the energy sources that need to be disconnected or isolated. It may even be able to produce images that reveal the specific position of the harmful energy source. Read More: Electrical Panel Lockout Switches With Safety

Turn off the machine

The lockout Tagout method should include a list of the procedures to be taken to do this and specific instructions on how to shut down the equipment. Some devices or equipment need several steps to be completed before they may be shut down. Moreover, Valve Lockout is the major equipment that is used to block harmful and hazardous materials from pipes supplies.

Lockout and tag all energy isolators

Make use of the locks and tags that have been assigned to you. In most cases, this requires permission. If more than one person is engaged in the maintenance or service of the machine or equipment, each individual must connect their lock or tag to the energy isolating device.

From the Loto Kit, using Electrical Lockout Devices and Equipment can improve employee productivity and efficiency. It also prevents issues from arising in the first place, which leads to a safer working environment.

These are the Popular Safety House LOTO Products

>> MCB Lockout

>> Group Lockout Box

>> Scaffold Tag

Common Yet Useful Lockout Devices

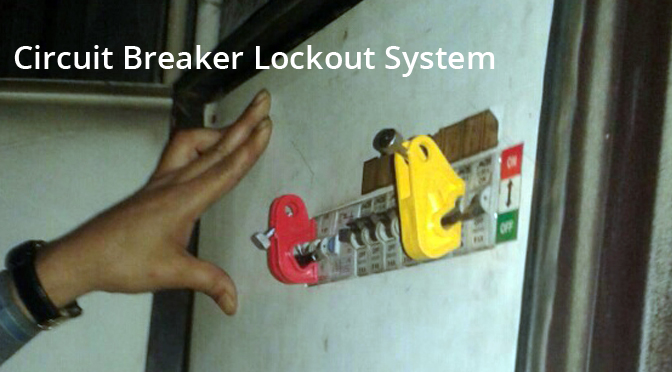

1. Circuit Breaker Lockout Devices: These are automatic electrical switches that are designed to protect circuit boards from overload or short circuit. At Lockout India, circuit breakers are designed to work on most varieties of breakers including single-pole and multi-pole breaker specifications.

These are used to isolate a given breaker in a panel so there’s no further need to lockout the entire breaker. Molded from durable plastics, their basic task however is to detect faulty conditions and automatically open the circuit.

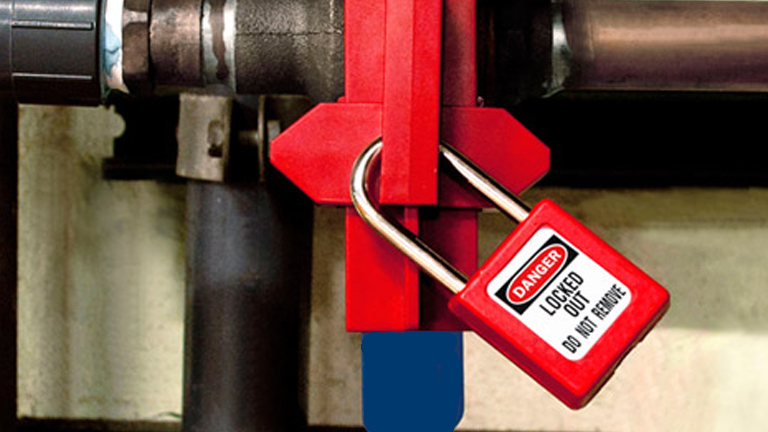

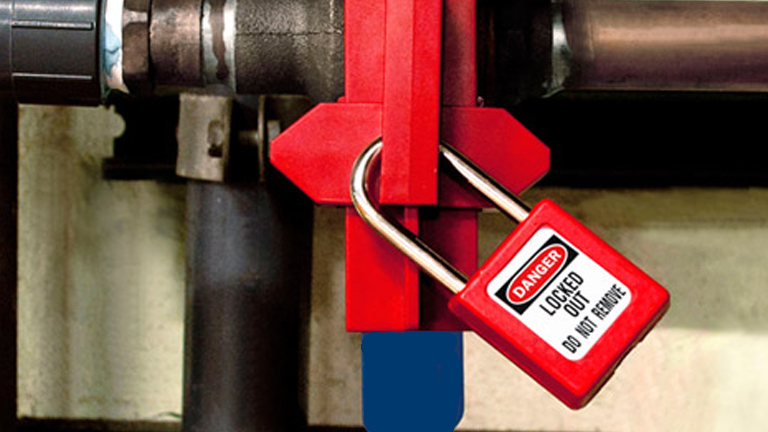

2. Valve and Pneumatic Lockout Devices: Just like electricity, gases and fluids can be significantly hazardous. They tend to move at tremendous pressures and can severely injure if released inappropriately. Valve lockout devices are designed to isolate such hydraulic energy sources. There are different types of available valves such as ball valves, butterfly valves, gate valves, and pneumatic disconnects.

3. Plug Lockout Devices: Portable cords and connected plugs are a common site in work facilities. However, it is important to isolate such electrical sources into a socket using a power plug if one needs to comply with OSHA’s standards.

Our secure design locks onto prongs to prevent them from getting inserted into wall outlets. It can be used with your existing lockout hasps and padlocks.

4. Cable Lockout Devices: This device secures, holds, and locks out electrical power handles and gate valves. Cable lockout devices are conveniently isolated energy and are easy to use. They further ensure successful lockout across multiple energy sources and stop the workforce from actualizing devices while the maintenance is being carried out.

5. Lockout Hasp: Hasp lockout devices are an integral part of a successful safety program. They provide multi-person lockout and multiple padlocks can be applied hasps, allowing the energy to be isolated by more than one worker at a time.

Energy cannot be worked upon until each worker unlocks the padlock. Our wide range of hasps includes dielectric hasps, dual jaw hasps, electroplated hasps, labeled hasps, premier lockout hasps, and non-conductive hasps.

When are these devices used?

– While machinery is being serviced or maintained

– While installing new equipments and machineries

– When a safety device needs to be bypassed or removed

– Moving machineries and equipments

– Any machinery prone to unexpected start-up

Most importantly, whenever a lockout safety device is applied to a machinery, it must remain under exclusive observation and shouldn’t be removed by any unauthorized personnel. manufacturer of lockout products

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Also read: How to Use Electrical Lockout Devices and Equipment?

Also read: Types of Lockout Tags & Its Usage for Industrial Safety

Miniature Circuit Breaker (MCB) Lockout System

A fuse, as we all know, needs to be replaced once operated. These days, most of the circuits come with an alternative and that is a Miniature Circuit Breaker (MCB). An MCB Lockout is an electromagnetically device which operates as an automatic switch and protects an electrical circuit from damage caused by excess current or overheating, generally caused by a short-circuit or a faulty design. Unlike a fuse, when an overload is detected, an MCB doesn’t have to be replaced. It can be reset, either manually or automatically and continue to function and thus offers an improved functioning and operational safety without additional costs. In a nutshell, an MCB functions as a switch that automatically turns off when the flowing current passes the allowed limit.

A miniature circuit breaker comprises of two contacts, fixed and moveable. A solenoid forces the moveable contact to disconnect from the fixed one whenever the current exceeds the allowed limit, thereby stopping the current flow through the circuit. This mechanism protects from current over load. However, a bi-metallic strip is used to protect from overheating and increase in temperature. The overload causes the temperature to rise and subsequently, the bi-metallic strip heats and deflects. The deflection then releases the trip latch and separates the contacts.

Miniature circuit breakers serve two purposes. They function as a fuse and as a switch. By toggling the switch to the ‘off’ position, the circuit can be opened for safety and maintenance purposes. Before the maintenance process begins, miniature circuit breakers need to be locked and tagged out. This ensures that they are not accidentally reactivated while maintenance is still in process.

While there are numerous companies dealing in lock out devices, Lockout India manufactures safe, effective and reliable universal miniature circuit breakers lockout devices that work on most circuit breakers throughout the world. They comply with OSHA’s safety standard 1910.147 and ensure that electrical energy sources are locked out for optimum work safety. These lockout devices are manufactured using durable plastics and effectively lock out the circuit breakers. These can be used for single, double, triple and quadruple pole MCB and can be easily installed using a screwdriver.

Checkout Our Other Lockout Tagout Products:

- MCB Lockout

- Lockout Padlocks

- Scaffold Tag

Enquire Now

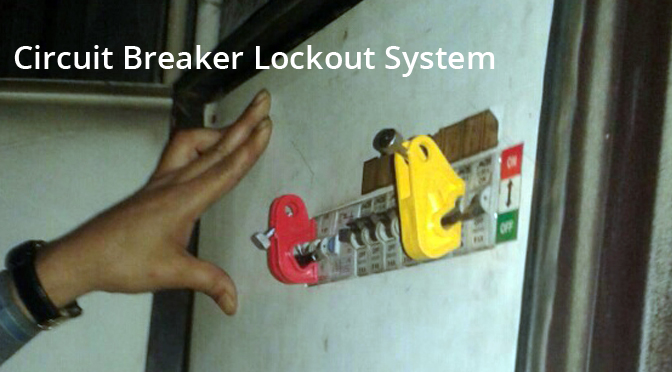

Circuit Breaker Lockout System

You must have observed MCB’s (Miniature Circuit Breaker) installed in your house. When you switch on or shut-down the appliance, the electricity of an entire floor gets affected. This is because all the circuits in the floor are connected with the MCB Lockout and by turning off the main switch, the lights go out. However, this is not the prime task of a circuit breaker but to protect the appliance and the people from potential electrical shocks and faults. In other words, Circuit Breakers are the appliances that blocks possible electrical short-circuits and helps maintain the flow of electricity.

A lot of people fail to comprehend the reason as to how Circuit Breakers come under the OSHA guidelines. As per OSHA’s standard 29 CFR 1910.147, all the devices that are dangerous and can cause accidents must be disconnected from all kinds of appliances, including Circuit Breakers so that the machines can’t operate itself in absence of workers. And since Circuit Breakers are basically like a switch with on/off system, it’s required to count them in Lockout-Tagout procedure.

Circuit breakers lockout system involves locking out the switches of the circuits through circuit breaker lockout equipment. The kit includes yellow rail assembly, 2 x 1-way pins, 1 x 2-way pins, 1 x cup pin, pin holder, and self tapping screws which come specifically designed for each panel. The process of killing the switches is very easy through the Lockout Kit.

There are numerous lockout-tagout service providers in the country. However, not all of them deliver quality products to their customers. ‘Safety House’ is a trusted company that has been in business since a considerable amount of time and has hundreds of satisfied clients. So make sure to choose the best LOTO service provider for your establishment which meets your requirements.

Checkout Our Other Lockout Tagout Products:

- Lockout hasp

- Group Lockout Box

- Lockout Station

- Valve Lockout

Enquire Now

Checklist For Better Use of Lockout/Tagout Program

Lockout/ Tagout acceptance in your workplace is an essential safety requirement. Preventing the unpredictable accidents of dangerous gasses or energies during service and maintenance ensures the safety of workers and helps to build a productive work environment. Lockout Tagout Products require proper adoption and implementation for workplace and employees. According to a report of Occupational Safety and Health Administration (OSHA), around three million people working with big equipment or machines face the risk of injuries if lockout/ tagout (LOTO) is not properly implemented. This blog post will provide few tips to help your company stay disciplined.

Choose The Right Device: The lockout padlock is one of the important parts of LOTO family. Valves, circuit breakers, switches, etc. are just some of the machines that require lockouts. Sometimes purchasing the right type of lockout may seem overwhelming as these products come in many variants.

Before buying a padlock for your workplace, few things are going to help you a lot:

1. Knowing the exactly right product and use devices verified as per OSHA standard.

2. Make a list of machines that may need lockout devices.

3. Always use standardized goods and tools to keep devices organized.

Lockout Station is an effective way to hold critical devices. This product not only stores important devices, but also they save space, time and efficient operations.

Complete Document Strategy: Lockout implementation needs to be documented by process. This process will help to remove any possible confusion about the ability of management and workers. Documentation also provides employees with valuable training tips. Fixed documentation provided by OSHA is required, given the differences in workplaces and machines, not every Lockout procedure will be the same. It Is very important to make sure the systems are as efficient as possible.

Establish An Attentive Training Program: Careful and thorough training is an essential part of a successful lockout program. All workplaces need to be trained according to their need. It is imperative for each and every worker to his role. Work should be explicitly assigned and defined to the appropriate employee. Strong communication is required to develop among all employees so that they clearly alert affected employees when a lockout device is being placed and removed. Every padlock has a space to write worker’s name.

Careful Evaluation: A careful evolution is a crucial for development. Lockout training and written procedures can be counted as a success, only if they are used in actual maintenance situations. Analysis is important to make sure that the training exercises, procedure, and devices are working properly.

Take a look at LOTO products at www.lockoutindia.com and decide if the products shown on the website will meet all your criteria necessary protect employees while working.

Checkout Our Other Lockout Tagout Products:

- Lockout Hasp

- Group Lockout Box

- Lockout Padlocks

- Valve Lockout

Enquire Now