Don’t Let Safety Slip Away: A Deep Dive into Valve Lockout Best Practices

Ensuring Workplace Safety: A Close Examination of Valve Lockout Strategies

In industries where hazardous materials flow through pipelines, valves serve as crucial control points. These valves regulate the flow of liquids, gases, and other substances, ensuring smooth operation. However, when it comes to maintenance, repair, or any situation requiring valve isolation, ensuring safety becomes paramount. This is where valve lockout procedures play a vital role.

Understanding Valve Lockout

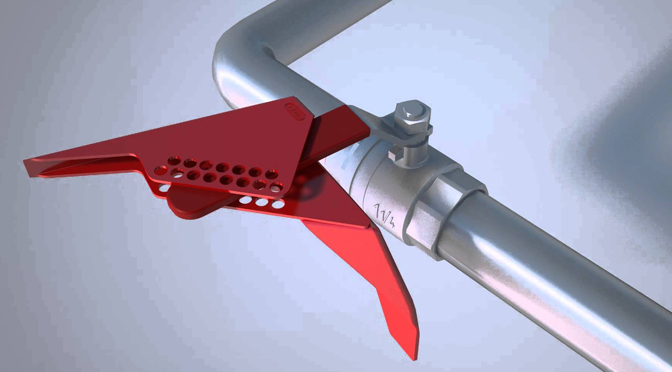

Valve lockout is a safety procedure designed to prevent the accidental or unauthorized opening of valves during maintenance or repair work. By using specialized lockout devices, such as padlocks, hasps, and tags, valves are physically locked in a closed or open position, depending on the situation. This prevents unexpected release of hazardous substances, which could lead to accidents, injuries, or environmental damage.

Importance of Valve Lockout

The importance of valve lockout cannot be overstated in industries where safety is a top priority. Failure to properly lock out valves during maintenance or repair activities can result in catastrophic consequences, including chemical spills, fires, explosions, and even loss of life. Therefore, implementing robust valve lockout procedures is essential for protecting personnel, equipment, and the environment.

Key Components of Valve Lockout

A successful valve lockout program consists of several key components:

- Lockout/Tagout (LOTO) Procedures: Comprehensive LOTO procedures should be developed and followed for each valve isolation task. These procedures should include detailed instructions on how to properly lock out valves, including the use of lockout devices and tags.

- Training and Education: Proper training and education are essential for all personnel involved in valve lockout procedures. Employees should be trained on the importance of valve lockout, how to identify lockout points, and how to use lockout devices correctly.

- Lockout Devices: Choosing the right lockout devices is crucial for effective valve lockout. Devices should be durable, tamper-resistant, and capable of withstanding the operating environment. Common lockout devices include valve lockout hasps, ball valve lockouts, and gate valve lockouts.

- Lockout Tags: Lockout tags provide essential information about the status of the valve and the reason for its lockout. Tags should be prominently displayed and include details such as the name of the authorized employee, the date of lockout, and any specific hazards associated with the valve.

Best Practices for Valve Lockout

To ensure the effectiveness of valve lockout procedures, the following best practices should be followed:

- Perform a Risk Assessment: Before initiating any valve lockout procedure, conduct a thorough risk assessment to identify potential hazards and determine the appropriate lockout measures.

- Use Standardized Procedures: Develop standardized lockout procedures for different types of valves and isolation tasks. Ensure that all employees are familiar with these procedures and follow them consistently.

- Implement a Lockout/Tagout Program: Integrate valve lockout procedures into a comprehensive Lockout/Tagout (LOTO) program to ensure consistency and compliance with regulatory requirements.

- Provide Adequate Training: Train all personnel involved in valve lockout procedures on the proper use of lockout devices, the importance of following procedures, and the potential consequences of failure to lock out valves.

- Regular Inspections and Audits: Conduct regular inspections and audits to ensure that valve lockout procedures are being followed correctly. Address any deficiencies or non-compliance issues promptly.

Compliance with Regulations

Compliance with relevant regulations and standards is essential for ensuring the effectiveness of valve lockout procedures. In the United States, the Occupational Safety and Health Administration (OSHA lock) has established specific requirements for lockout/tagout procedures under 29 CFR 1910.147. Similarly, other regulatory bodies around the world have their own guidelines governing lockout procedures. It is imperative for organizations to familiarize themselves with these regulations and ensure compliance to avoid penalties and legal consequences.

Conclusion

Valve lockout is a critical safety procedure that plays a vital role in preventing accidents, injuries, and environmental damage in industries where hazardous materials are present. By implementing robust lockout procedures, providing adequate training, and ensuring compliance with regulations, organizations can protect their personnel, equipment, and the environment from potential harm. Remember, safety should never be compromised, and valve lockout is a crucial step in safeguarding against unforeseen hazards.

Valve Lockout Systems: Safeguarding Against Hazardous Energy Releases

In industrial settings, safety is paramount, especially when dealing with potentially hazardous energy sources. Valve lockout systems are indispensable safety lockout products designed to prevent unintended release of energy, securing the well-being of workers and minimizing the risk of accidents. In this article, we’ll explore the significance of valve lockout systems, their benefits, and how they contribute to a safer work environment.

The Role of Valve Lockout Systems in Safety

Valve lockout systems are engineered to isolate valves, preventing their operation during maintenance, repairs, or servicing. They are an essential component of any comprehensive safety lockout program and play a crucial role in safeguarding workers against unexpected energy releases. These systems are particularly effective in environments where various energy sources are present.

Understanding Valve Lockout

Valve lockout systems typically consist of lockout devices that fit over valve handles, preventing them from being turned or operated. These devices are often accompanied by lockout tags and labels, providing clear indications that the valve is locked out for maintenance. By immobilizing valves, these systems reduce the risk of hazardous substances, such as steam, gas, or chemicals, escaping and causing potential harm.

Benefits of Valve Lockout Systems

- Enhanced Worker Safety: Valve lockout systems provide a physical barrier that inhibits unauthorized or accidental valve operation. This minimizes the chances of workers being exposed to dangerous energy releases, contributing to a safer working environment.

- Compliance with Regulations: Implementing valve lockout systems is not only a best practice but also a legal requirement in many industries. Organizations that adhere to safety regulations, such as those outlined by OSHA, showcase their commitment to employee welfare and can avoid costly penalties.

- Versatility in Application: Valve lockout systems can be adapted for various types of valves, including ball valves, gate valves, and butterfly valves. This versatility ensures that different valve systems can be effectively locked out, regardless of their design or function.

How Valve Lockout Systems Work?

- Identification: Identify the valve to be locked out and its energy source.

- Selection: Choose the appropriate valve lockout device based on the valve type and size.

- Application: Attach the lockout device over the valve handle, immobilizing it in the off or closed position.

- Securing: Apply a lockout padlock to the device, ensuring the valve remains in the locked-out state.

- Tagging: Attach a lockout tag indicating the reason for the lockout and the responsible personnel.

Conclusion

Valve lockout systems are pivotal in maintaining a secure working environment, preventing hazardous energy releases that could lead to accidents or injuries. By implementing these safety lockout products, organizations prioritize worker safety, adhere to regulations, and create a culture of responsible energy control. Valve lockout systems stand as a testament to the commitment to safety and employee well-being in any industrial setting.

Remember, investing in quality valve lockout systems and ensuring proper training for employees on their usage is essential for the overall success of your safety lockout program.

Checkout Our Other Products:

- Loto Kit

- Lockout hasp

- Valve lockout

- Lockout station

- Lockout station

What Are The Uses And Applications Of Valve Lockouts?

Valve lockout is a device that is designed to isolate the energy running in the pipe to avoid and prevent mishappening when any repair work is going on. It plays an important role in the small and big industries that deals with high amount of energy. It is used in industries to close off energy sources such as electricity, gasses, chemicals, etc. In other words, we can say that valve devices are used to lock the energy source when no workers are working on the machinery or when repair or maintenance is going on the energy pipeline or in the machinery.

The main intention of the valve lockout, i.e., also known as LOTO valve, is to ensure the safety of the worker and keep industry machinery safe from any type of miss-happening.

Top Features Of Valve Lockout

- Loto Valves are made from industrial-quality steel and nylon for their long life.

- It is specially designed for locking high-pressurized energy pipes at right angles.

- They are corrosion-resistant and can resist high and low temperatures.

- The safety factor of Loto valve devices varies from industry to industry and its uses.

- It is very to deploy and easy to use.

Different Types Of Valves Lockout

Applications Of Valve Lockout

Valve Lockout is widely used in different types of industries to avoid the industrial miss-happenings caused by unanticipated equipment startups and unexpected energy releases. Let’s take a glance at what are the different industries in which valve Loto is essential.

- A Loto valve device is used in the fire protection industries to control high water pressure.

- It is used in industries that deal with different types of gases, such as neon, argon, nitrogen, LPG, etc.

- Valve lockout devices are used in agrochemical, fluoro chemical, and base chemical industries.

- It is also used in warehouses of many industries to maintain the quality of the raw material.

Advantages Of Valve Lockout Devices

Lockout Tagout Products reduce the risk of injuries in the case when the machinery is switched on by mistake. It also decreases the chances of death caused by huge energy releases such as steam blasts, poisonous gas leakage, etc. It also saves workers from corrosive chemicals and electrical arc flashes. It saves the worker’s life as well as save industrialist from legal actions.

Valve lockouts also save the compensation that industrialist gives to their workers if any miss-happening happen with their workers. It creates a fear-free work environment that creates confidence and trust among the workers. If you are an industrialist or entrepreneur and deal in different types of energies, then you can contact a trusted lockout supplier to get the best quality lockout devices.

Checkout our popular products:

- Loto Kit

- Scaffold Tag

- Lockout Padlocks

- Key box

Butterfly Lockout Device – A Complete Buying Guide

Lock devices play an important part in industries, whether it comes to giving security to the industrial warehouse or locking the flow of different gasses and chemicals. Butterfly Lockout Devices are very efficient devices helping many industries to flourish with protection.

Butterfly lockout devices are available in the market that is used in the gas, air, high-temperature service, and fire protection industry. Many agrochemicals, fluoro chemical, and base chemical industries are also using it for the good functionality and reliability of their industries.

If you are running a gas or chemical industry or providing services similar to fire protection, then you must have good quality butterfly valve lockout devices for your protection. Still, if you aren’t ready for it, here are some quick tips for finding the best butterfly lockout devices for your industry.

5 Quick Things To Check Before Buying A Butterfly Lockout Device

1] Where To Use?

Many types of butterfly valve lockout devices are available in the market, so before buying the butterfly lockout device, you must have proper knowledge of its application. The reason is that this valve lockout device is used in various appliances in industries as they use it to regulate and isolate the flow of water, gas, and air.

2] Metal Quality

Before buying any material device, you must look after its quality because it gives you an overview of the product’s life. So, it is very important to check the quality of the material before buying a butterfly valve lockout to avoid future problems like water or gas leakage from the device. As per the standard of metal quality, the device comes in various ranges, such as 201 stainless steel, 304 stainless steel, or steel, and they can be zinc plated, nickel-plated, and chrome-plated.

3] Design

Butterfly lock devices come in various ranges based on their design and use. If you have to use these locks for your home, ensure that the device meets your home’s aesthetics. But in case you are buying this valve lockout for industrial uses, then you must consider its application, whether it will be in use to control and regulate industrial gas or fuel.

4] Pressure Rating

Industries mostly use Butterfly valve lockout to regulate or isolate the flow of air, water, gas, or any other fluid. So you must check the pressure range handled by your butterfly lockout device because high-pressure fluids can harm the pipe, and it might have chances that your butterfly locking system will fail.

5] Butterfly Lock Device Valve Size

There are mainly three types of valves in the Butterfly lockout devices: concentric butterfly valves, Double-eccentric butterfly valves, and Triple-eccentric butterfly valves. You can choose among these three types of butterfly valves according to your home or industrial use.

To Wrap Up

The butterfly valve lockout device is essential for industries as well as homes for controlling the flow of fluid. In the past, this valve lockout technology was only used in oil industries, fuel handling systems, power generation, and compressed air industries. As time evolves, the device is also being used in the home door, windows, and many other things. If you are on the lookout for the best butterfly lockout supplier, you can explore our catalogs to get well-engined valve lockout devices.

Checkout Top Selling Lockout Products:

- Lockout Kit

- Lockout hasp

- MCB Lockout

- Scaffold Tag

What Is Valve Lockout Devices And Its Uses?

Have you ever heard about the valve lockout device? It is the safety device accessed for effective lockout procedures in the work environment.

It allows the industry workers to isolate or close off the stored energy such as electricity and hydraulic pressures. The major purpose of valve lockout is to prevent harmful accidents during repairs and maintenance.

In simple words, the valve lockout is used to close off pressured valves to make sure that the machinery, which is valve operated, remains switched off when workers are performing maintenance work.

Moreover, this device is often attached over the valve’s operational part before securing it in place with the hasps or padlocks. If you want to know about the valve lockout device uses, then you should read the below section carefully.

Features of the valve lockout

Upon reading the above section, you will know the important purpose of valve lockout. Here are the potential features of the valve lockout. In addition, it helps you understand the importance of spending on this device.

- Valve lockout is extremely easy to use and install

- It is made of nylon and industrial-grade steel material for durability

- It is powerful enough to lock commonly accessed sizes of pressured valves at the right angles.

- The valve lockout device has excellent resistance to corrosion, high temperature, and solubility.

- It has a high safety factor and has become applicable to different manufacturing fields.

Uses of the valve lockout devices

The purpose of valve lockout is extensive, and thus it is widely used in different industries where safety is a big concern. You can use the valve lockout for the valves that contain storage tanks, gate valves, shut-off valves, and much more.

However, the valve lockout helps eliminate the industrial mishappenings throughout the world caused by unanticipated equipment startups and unexpected energy releases.

Furthermore, even though valve lockout device uses are diverse, the most highlighted usage is that it locks most types and sizes of valves. It ensures safety and gives ultimate protection to the workers. It has become the must-have equipment in the industry where the risk of injury and accident is high for the workers.

Since it acts as the best investment compared to the disposable and environmentally unsustainable alternative, you will save more of your money.

Moreover, to avoid hassles, you should choose the right valve lockout suitable for your industrial requirements. Most importantly, you should join hands with the reliable Safety Lockout Products manufacturer to get high-quality devices.

As you have realized, do you want to purchase the best quality valve lockout devices? Well! You can shop at a reliable destination and get high-quality lockout values at a reasonable rate.

Top Valve Lockout Devices From Safety House Loto

Common Yet Useful Lockout Devices

1. Circuit Breaker Lockout Devices: These are automatic electrical switches that are designed to protect circuit boards from overload or short circuit. At Lockout India, circuit breakers are designed to work on most varieties of breakers including single-pole and multi-pole breaker specifications.

These are used to isolate a given breaker in a panel so there’s no further need to lockout the entire breaker. Molded from durable plastics, their basic task however is to detect faulty conditions and automatically open the circuit.

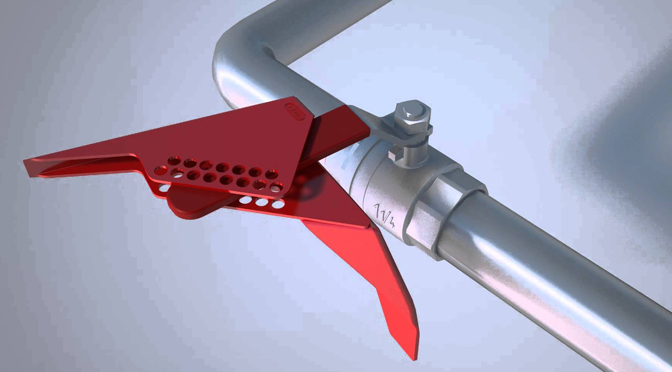

2. Valve and Pneumatic Lockout Devices: Just like electricity, gases and fluids can be significantly hazardous. They tend to move at tremendous pressures and can severely injure if released inappropriately. Valve lockout devices are designed to isolate such hydraulic energy sources. There are different types of available valves such as ball valves, butterfly valves, gate valves, and pneumatic disconnects.

3. Plug Lockout Devices: Portable cords and connected plugs are a common site in work facilities. However, it is important to isolate such electrical sources into a socket using a power plug if one needs to comply with OSHA’s standards.

Our secure design locks onto prongs to prevent them from getting inserted into wall outlets. It can be used with your existing lockout hasps and padlocks.

4. Cable Lockout Devices: This device secures, holds, and locks out electrical power handles and gate valves. Cable lockout devices are conveniently isolated energy and are easy to use. They further ensure successful lockout across multiple energy sources and stop the workforce from actualizing devices while the maintenance is being carried out.

5. Lockout Hasp: Hasp lockout devices are an integral part of a successful safety program. They provide multi-person lockout and multiple padlocks can be applied hasps, allowing the energy to be isolated by more than one worker at a time.

Energy cannot be worked upon until each worker unlocks the padlock. Our wide range of hasps includes dielectric hasps, dual jaw hasps, electroplated hasps, labeled hasps, premier lockout hasps, and non-conductive hasps.

When are these devices used?

– While machinery is being serviced or maintained

– While installing new equipments and machineries

– When a safety device needs to be bypassed or removed

– Moving machineries and equipments

– Any machinery prone to unexpected start-up

Most importantly, whenever a lockout safety device is applied to a machinery, it must remain under exclusive observation and shouldn’t be removed by any unauthorized personnel. manufacturer of lockout products

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Also read: How to Use Electrical Lockout Devices and Equipment?

Also read: Types of Lockout Tags & Its Usage for Industrial Safety

All About Ball Valve Lockout Devices

A work facility is an inexhaustible source of hazardous energy. Energy sources include electrical, hydraulic, mechanical, pneumatic, thermal, etc. and can be detrimental to work forces within the premises. A lot of industrial mishappenings around the world are caused by unexpected energy release and unanticipated equipment startup.ball valve lockout devices

A lockout safety method locks out such energy-isolating devices and ensures that they cannot be operated until the lockout device is removed. It simply aims at improving safety, maintaining compliance and encouraging sustainability. However daunting it might seem, it’s imperative that all the layers of the organization work towards implementing a sustainable lockout safety program. Without seamless cooperation, a lockout system would fall apart.

Of all the safety Lockout Tagout Products, today, we’ll discuss about Ball Valve Lockout. Ball Valve is a quarter-turn, straight-through valve that suitably transfers liquids, compressed air, clean gas and slurries (liquids with suspended solids). It uses a hollow and perforated ball to control the flow through it. The ease of operation, repair and versatility that comes with ball valves is what leads to its extensive industrial use. Ball valves have a round closure element that permits consonant sealing stress. Getting its name from the ball that rotates within to close and open the valve, these devices are used where a taut shut-off is required and are a fine source for control applications. Durable and reliable even after jagged use, these safety devices are often preferred to gate and globe valves. Ball valves involve the use of materials such as nylon, delrin, synthetic rubbers and polymers and that imparts an excellent sealing ability. However, there is a potential of wear on the seats and it renders it unsuitable for throttle applications.

Types of Ball Valves:

Valve operation in each type remains the same. The only difference is how these valves are manufactured and assembled. Each design has its own benefits.

– Split body Ball Valve

– Top entry Ball Valve

– End entry Ball Valve

– Double trunnion Ball Valve

– 3-piece Ball Valve

– Lubricated/Non-lubricated Ball Valve

Advantages that a ball valve renders:

– Smooth and straightforward actuation

– Swift opening and closing

– More compact and lighter than a gate valve

– Bubble-tight service

– Wide choices, thus allowing flexibility

– Multi-port designs

– Reliable in high-temperature and high-pressure applications

Used in a variety of applications such as gas processing and storage, fire safe protection services, chlorine manufacturing, and flowing systems, ball valves. Some typical applications are:

– Low point drains in fluid services

– High-point vents in fluid services

– Instrument root valves

– Steam service

– Feed water systems

At Lockout India, it’s all about committing to quality, performance and service. We are the leading manufacturer of various types of Ball Valve Lockout devices and our products satiate different industrial requirements and convincingly control the flow of diverse gases and fluids.

Checkout Our Other Lockout Tagout Products:

- Lockout Kit

- Group Lockout Box

- Lockout Station

Enquire Now