Lockout Padlocks vs. Standard Padlocks: What’s the Difference?

When it comes to workplace safety, understanding the tools designed for specific tasks is critical. Padlocks, for example, are commonly used for securing property or equipment. However, when safety is a concern, Lockout Padlocks play an essential role. At first glance, these might seem similar to standard padlocks, but their purpose, design, and functionality are distinct. Let’s explore the key differences between lockout padlocks and standard padlocks, emphasizing their role in enhancing safety through Lockout Tagout (LOTO) systems.

What Are Standard Padlocks?

Standard padlocks are everyday security tools designed to protect valuables and restrict unauthorized access. You’ll typically find them securing gates, lockers, or cabinets. Key features of standard padlocks include:

- Purpose: Focused on theft prevention.

- Design: Made with robust materials like steel to resist tampering.

- Key Systems: Often shared or interchangeable keys, convenient for general use.

While these padlocks are effective for securing physical property, they lack the specialized features required for workplace safety systems.

Understanding Lockout Padlocks

Lockout Padlocks are specially designed for use in Lockout Tagout (LOTO) systems, ensuring the safety of workers during equipment maintenance or servicing. Key characteristics include:

- Non-Conductive Materials: Many lockout padlocks are made with non-conductive materials like plastic or nylon to prevent accidental electrical conduction.

- Unique Key System: Each lockout padlock has a unique key, ensuring that only authorized personnel can remove it.

- Durable Tags: Often accompanied by tags or labels for clear communication, identifying who locked the equipment and why.

- Color Coding: Available in various colors for quick identification, aiding in organizing multiple lockout procedures.

These features make lockout padlock indispensable for isolating energy sources and preventing accidental equipment activation.

Key Differences Between Lockout Padlocks and Standard Padlocks

1. Purpose

- Standard Padlock: Focused on securing property and preventing theft.

- Lockout Padlock: Specifically designed for safety purposes, ensuring equipment remains de-energized during maintenance.

2. Material Composition

- Standard Padlock: Typically made of metal for durability and security.

- Lockout Padlock: Often feature non-conductive materials, ensuring safety in environments with electrical hazards.

3. Keying Systems

- Standard Padlock: Keys can be duplicated or shared for convenience.

- Lockout Padlock: Feature a unique key-to-lock ratio, preventing unauthorized removal and enhancing safety protocols.

4. Design and Visibility

- Standard Padlock: No specific emphasis on visibility or labeling.

- Lockout Padlock: Bright colors and customizable labels make them highly visible and informative.

Why Are Lockout Padlocks Essential for Safety?

Lockout Padlocks form a vital part of the Lockout Tagout (LOTO) system, a safety protocol mandated by regulatory bodies like OSHA. These padlocks help in:

- Energy Isolation: Ensuring all energy sources are locked out before maintenance begins.

- Accident Prevention: Preventing accidental activation of machinery, reducing risks of injuries or fatalities.

- Accountability: Clear labeling and unique keys ensure only authorized personnel can access locked-out equipment.

By using lockout padlock, businesses can meet safety compliance standards and foster a safer workplace environment.

How to Choose the Right Lockout Padlocks?

When selecting lockout padlocks, consider the following:

- Durability: Opt for locks resistant to harsh environments.

- Non-Conductive Materials: Essential for electrical applications.

- Key Management System: Ensure a unique key system to prevent duplication.

- Compatibility with Tags: Ensure they work seamlessly with lockout tags and devices.

Reputable lockout suppliers, like Safety House Loto, provide high-quality Lockout Tagout products, including padlocks that meet industry standards.

Conclusion

While standard padlocks are great for securing physical property, lockout padlocks are an essential component of workplace safety. Designed to prevent unauthorized access and accidental activation of equipment, they are a cornerstone of any Lockout Tagout system.

For businesses prioritizing safety, choosing the right lockout products is crucial. Partnering with reliable lockout suppliers, such as Safety House Loto, ensures you get top-notch solutions tailored to your needs. By investing in lockout padlocks and adhering to LOTO protocols, you can create a safer and more compliant workplace.

Understanding the difference between these two types of padlocks not only helps in selecting the right tools but also reinforces the importance of safety in every industry.

Why Every Facility Needs High-Quality Lockout Padlocks: Top Reasons and Benefits

In today’s industrial environment, ensuring worker safety is a top priority. One of the most effective ways to maintain safety in hazardous workspaces is through the use of Lockout Tagout (LOTO) systems. Lockout Padlocks, a critical component of LOTO, help prevent accidental machine startups during maintenance or repair activities. This blog explores the top reasons why every facility should invest in high-quality Lockout Padlocks and the benefits they provide.

1. Prevent Accidental Machine Startups

One of the primary reasons for using Lockout Padlocks is to prevent accidental machine activations. During equipment maintenance or repair, the unexpected startup of machinery can lead to severe injuries or even fatalities. By using Lockout Tagout products, including padlocks, workers can securely isolate energy sources and prevent unintentional reactivation.

How Lockout Padlocks Work: Lockout Padlocks are designed to fit onto energy control devices like circuit breakers, valves, and switches. When locked, the machinery or system remains inoperative, ensuring that only authorized personnel can remove the lock and restart the equipment after the maintenance is complete.

2. Comply with Safety Regulations

Adhering to industry safety standards is not just about preventing accidents—it’s also about legal compliance. Many countries have stringent regulations mandating the use of Lockout Tagout systems, such as OSHA (Occupational Safety and Health Administration) in the United States. Failure to comply with these regulations can lead to hefty fines and penalties. High-quality Lockout Padlocks ensure your facility meets these safety standards, protecting both your employees and your business.

3. Protect Employees and Minimize Downtime

Another significant advantage of using high-quality Lockout Padlocks is the protection they provide for your workforce. Employee safety is paramount, and a well-implemented LOTO system drastically reduces the risk of workplace accidents. By safeguarding workers from hazardous energy, Lockout Padlocks allow maintenance and servicing tasks to proceed without fear of sudden machine startups. This protection ultimately minimizes injuries, enhances productivity, and reduces downtime associated with accidents.

4. Customize Your Lockout System

Lockout Padlocks are versatile and can be customized to meet the specific needs of your facility. Many manufacturers offer padlocks in various sizes, colors, and keying options. These customizations allow for efficient lockout procedures, helping workers quickly identify which energy sources are locked out and who is responsible for the lock. Customizing your Lockout Tagout products ensures that your system is both effective and easy to use.

Examples of Customization Options:

- Color Coding: Different colors can be assigned to various departments or types of equipment.

- Keying Options: Padlocks can be keyed differently for each user or keyed alike for shared access.

5. Enhance Security with High-Quality Materials

When it comes to Lockout Padlocks, quality matters. Investing in durable, tamper-resistant padlocks made from high-grade materials ensures that your LOTO system is robust and secure. High-quality padlocks are designed to withstand harsh industrial environments and offer superior resistance to tampering or accidental damage. Choosing reputable Lockout Tagout products increases the longevity of your system and ensures that your workers remain protected.

6. Promote a Safety-First Culture

Investing in a high-quality LOTO system, including Lockout Padlocks, sends a clear message to your employees: safety comes first. By implementing effective safety measures, companies foster a safety-first culture where workers feel valued and protected. This positive environment encourages adherence to safety protocols, reducing accidents and increasing workplace morale.

7. Versatile Application Across Industries

Lockout Padlocks are not limited to a specific industry. Whether you’re in manufacturing, energy, chemical processing, or transportation, Lockout Tagout products can be used to isolate hazardous energy sources. Facilities with complex machinery or high-risk operations can especially benefit from the added layer of protection that Lockout Padlocks provide.

Conclusion: Invest in Safety with Lockout Padlocks

High-quality Lockout Padlocks are an essential component of any safety-conscious facility. By preventing accidental startups, complying with regulations, protecting employees, and promoting a safety-first culture, these padlocks provide substantial benefits across industries. Safety House Loto offers a wide range of Lockout Tagout products designed to meet the highest safety standards, helping facilities worldwide ensure worker protection.

Incorporating Lockout Padlocks into your LOTO system is a smart investment that protects your workforce and minimizes the risk of accidents. Whether you need customized solutions or high-quality padlocks that withstand industrial environments, ensuring you have the right products in place is essential for a safe and compliant workplace.

Training Your Team: Best Practices for Using Lockout Padlocks

Mastering Lockout Padlocks: Essential Training for Workplace Safety

In industrial settings, safety is paramount. One of the most effective ways to ensure a safe working environment is by using lockout padlocks. These devices prevent accidental machinery start-up during maintenance, safeguarding employees from hazardous energy. As a leading manufacturer of lockout products, Safety House Loto emphasizes the importance of proper training in using these essential safety tools.

Understanding Lockout Padlocks

These are specially designed to secure machinery and equipment in an off position. They are a critical component of Lockout/Tagout (LOTO) procedures, which are implemented to control hazardous energy and prevent accidents. These padlocks are uniquely keyed, ensuring that only authorized personnel can remove them.

Importance of Training

Proper training is crucial for effective lockout padlock use. It not only ensures compliance with safety regulations but also enhances the overall safety culture within an organization. Here’s how to train your team effectively:

1. Familiarize with LOTO Procedures

Begin by educating your team about the Lockout/Tagout process. Explain the significance of LOTO and how lockout padlocks fit into the overall safety strategy. Ensure that employees understand the potential risks of improper lockout and the importance of adhering to protocols.

2. Demonstrate Proper Use

Conduct hands-on demonstrations to show how to correctly apply and remove lockout padlocks. Highlight the specific steps involved, such as identifying energy sources, isolating machinery, and securing it with a padlock. Emphasize the need to verify that all energy sources are effectively locked out.

3. Highlight Key Features

Educate your team about the features of lockout padlocks. Discuss their durability, tamper-proof design, and the importance of using only designated locks for specific machinery. Explain why using standardized colors and labels helps in quick identification and reduces confusion.

4. Implement Real-World Scenarios

Simulate real-world scenarios where employees must use lockout padlocks. This practical approach helps reinforce learning and prepares them for actual situations. Encourage team members to ask questions and clarify any doubts during these exercises.

5. Regular Refreshers and Updates

Safety protocols and equipment can evolve over time. Schedule regular refresher courses to keep your team updated on the latest best practices. Reinforce the importance of maintaining a proactive approach to safety.

Benefits of Using Quality Lockout Padlocks

Choosing high-quality lockout padlocks is essential for ensuring the safety of your team. We provides padlocks that are built to withstand harsh industrial environments, offering reliability and peace of mind. Here are some benefits of using top-tier lockout padlocks:

- Durability: Made from robust materials, they resist damage and tampering.

- Security: Unique keying options prevent unauthorized access.

- Visibility: Bright colors and clear labeling enhance visibility, reducing the risk of oversight.

Creating a Safety-First Culture

Training your team in the use of lockout padlocks fosters a safety-first culture within your organization. It empowers employees to take responsibility for their own safety and the safety of their colleagues. This culture not only minimizes accidents but also boosts morale and productivity.

Conclusion

Investing in proper training for using lockout padlocks is a vital step towards achieving a safer workplace. By understanding the importance of these devices and implementing best practices, your team can effectively mitigate risks associated with hazardous energy. Safety House Loto, as a trusted manufacturer of lockout products, is committed to supporting you in your journey towards enhanced workplace safety.

By prioritizing training and the use of quality lockout solutions, you create an environment where safety is second nature, ensuring that every team member returns home safely at the end of the day.

Lockout Padlocks: Essential Safety Gear for Every Industry

In today’s industrial landscape, ensuring the safety of workers is paramount. Among the various safety measures employed, Lockout Tagout (LOTO) procedures stand out as one of the most effective in preventing workplace accidents. Central to the LOTO system are Lockout Padlocks, which play a critical role in safeguarding employees from hazardous energy releases. Safety House Loto offers a comprehensive range of Lockout Tagout Products, designed to meet the highest safety standards across various industries.

Understanding Lockout Tagout (LOTO)

Lockout Tagout is a safety protocol used to ensure that machines and equipment are properly shut off and not able to be started up again prior to the completion of maintenance or repair work. This system is crucial for preventing accidental energization, which can result in serious injuries or fatalities. Lockout Padlocks are used to secure the power sources of these machines, effectively isolating them from any unintended operation.

The Importance of Lockout Padlocks

1. Preventing Accidents

Lockout Padlocks are indispensable in preventing workplace accidents. By physically securing energy-isolating devices, these padlocks ensure that machinery remains inoperative while maintenance is being performed. This simple yet effective tool provides a clear visual indication that the equipment is locked out and should not be tampered with.

2. Compliance with Regulations

Compliance with occupational safety regulations is mandatory for all industries. Regulatory bodies such as OSHA (Occupational Safety and Health Administration) have stringent requirements for lockout procedures. Using high-quality Lockout Padlocks from Safety House Loto helps businesses comply with these regulations, thereby avoiding hefty fines and ensuring a safer work environment.

3. Versatility and Durability

Lockout Padlocks come in various shapes, sizes, and materials to cater to different industrial needs. We offers padlocks that are durable and resistant to harsh environmental conditions. These padlocks are designed to withstand extreme temperatures, corrosion, and physical tampering, ensuring long-lasting protection.

Key Features of Lockout Padlocks

1. High-Security Mechanisms

Lockout Padlocks are equipped with advanced locking mechanisms to prevent unauthorized removal. They come with unique key codes and non-duplicable keys to ensure that only authorized personnel can remove them. This high level of security is essential in maintaining the integrity of the lockout system.

2. Color-Coding and Identification

To facilitate easy identification, Lockout Padlocks are available in multiple colors. This color-coding system helps in distinguishing between different locks assigned to specific tasks or departments. Additionally, padlocks can be engraved or labeled with employee names, departments, or equipment details, providing an extra layer of security and accountability.

3. Ease of Use

User-friendly design is another crucial aspect of Lockout Padlocks. They are designed to be easy to apply and remove, even in challenging conditions. The simplicity of their operation ensures that workers can quickly and efficiently secure equipment, reducing downtime and enhancing productivity.

Implementing an Effective Lockout Tagout Program

1. Developing a Comprehensive LOTO Policy

To maximize the effectiveness of Lockout Padlocks and the overall LOTO system, businesses must develop a comprehensive LOTO policy. This policy should include:

- Clear Procedures: Detailed instructions on how to properly lock out and tag out machinery.

- Training Programs: Regular training sessions to educate employees on LOTO procedures and the importance of compliance.

- Periodic Audits: Routine inspections and audits to ensure that the LOTO system is being correctly implemented and followed.

2. Training and Education

Training is a critical component of any LOTO program. Employees must be thoroughly trained on the proper use of Lockout Padlocks and other Lockout Tagout Products. This training should cover:

- Identifying Energy Sources: Teaching employees how to identify and isolate different types of energy sources.

- Applying Lockout Devices: Demonstrating the correct application and removal of lockout devices, including padlocks.

- Emergency Procedures: Preparing employees for potential emergencies and ensuring they know the steps to take in case of an accidental lockout or other unforeseen events.

3. Regular Maintenance and Inspection

Regular maintenance and inspection of Lockout Padlocks and other LOTO devices are essential to ensure their continued effectiveness. Businesses should implement a schedule for:

- Inspecting Padlocks: Checking padlocks for signs of wear and tear, ensuring they remain in good working condition.

- Replacing Damaged Devices: Promptly replacing any damaged or worn-out lockout devices to maintain safety standards.

- Updating Procedures: Periodically reviewing and updating LOTO procedures to reflect any changes in equipment or operational processes.

Enhancing Workplace Safety through Our Lockout Products

We are committed to providing top-notch Lockout Tagout Products that adhere to the highest safety standards. Their extensive range of Lockout Padlocks is designed to meet the diverse needs of various industries, from manufacturing and construction to energy and utilities. By offering reliable and durable safety solutions,We helps businesses create safer work environments and protect their most valuable assets – their employees.

Conclusion

Lockout Padlocks are an essential component of any effective Lockout Tagout system. They provide a simple yet powerful means of ensuring that machines and equipment remain safely de-energized during maintenance activities. With the right Lockout Tagout Products, such as those offered by Safety House Loto, businesses can significantly reduce the risk of workplace accidents, comply with safety regulations, and promote a culture of safety within their organizations. Investing in high-quality Lockout Padlocks is not just a regulatory requirement; it is a commitment to the well-being of every worker.

How To Find The Lockout Padlocks As Per OSHA Standards?

When it comes to the potential of one employee mistakenly restarting a piece of equipment that another employee is working on, the employee’s sole safeguard is their lockout lock. Employees must learn how to operate their locks correctly and never give out their lock or key to guarantee complete control.

OSHA’s Lockout Tagout Regulations (1910.147)

Lockout Tagout devices must be robust, standardised, significant, and recognisable, according to OSHA Standard 29 CFR 1910.147.

- To achieve OSHA regulations, Lockout Safety Padlocks must meet the following requirements:

- Be able to tolerate long-term exposure to harsh weather conditions and be chemically resistant.

- Have a consistent color, shape, or size across the institution.

- Non-reusable, hand-attachable, self-locking, and non-releasable with a minimum unlocking strength.

- Use the tools to identify people and other recognizable data such as padlock numbers, metal marking, logos, department designations, etc.

Read more: Elements Of OSHA’s Lockout-Tagout Standard

A lockout programme consists of three key components

- Written Procedures: These protocols tell lockout participants what to do and when. They also outline the procedures for shutting down, isolating, and imposing and removing lockout. Such methods are only required for machines with two or more energy sources.

You should clearly state the following points:

- Specific machinery and their shutdown/isolation procedures

- Location of lockout mechanisms

- How to de-energize stored energy

- How isolation must confirm.

- Training Programs: Training is required for two types of employees: authorised and affected. Authorised employees maintain and service machines and are qualified to control hazardous energies. In contrast, affected employees work near the machines/equipment being serviced or repaired under lockout and must understand the hazards.

- Periodic Audits: Periodic audits ensure that energy control operations are still being done correctly, that employees are following protocols, and that they know their commitments.

What You Should Look In Lockout Padlocks & Its Benefits

Lockout Padlocks prevent mishaps by preventing equipment from being mistakenly turned on. This also prevents damage to the equipment and makes the workplace safer for everyone. Moreover, lockout Osha Lock is available in a variety of colors and is very durable, making them an excellent investment for any company.

As previously noted, are an essential component of any safety program. Workers may use Lockout Padlocks to ensure that machinery or equipment is not switched on while doing maintenance and repairs.

Safety house Lockout Padlocks may also be used to protect electrical panels, valves, and other potentially dangerous items. You may assist avoid accidents and injuries by clearly identifying dangers and shutting them out.

- Lockout padlocks are color-coded to make them easier to identify, and each Lockout Padlock may be allocated to a single employee. This guarantees that the equipment is only accessible to authorized employees.

- Padlocks, when utilized appropriately, may help make your workplace safer for everyone.

- It is a low-cost and easy approach to safeguarding the safety of your employees. Among the advantages are:

- Preventing mishaps by preventing equipment from being mistakenly turned on during maintenance.

- Disabling damaged equipment also protects it from additional harm.

- Lockout Padlocks are also useful for determining who has disabled the equipment since they are generally color-coded.

- This is significant because it makes everyone’s workplace safer.

Lockout Padlocks and Lockout Kits are a simple and efficient approach to increasing workplace safety and should be utilized wherever equipment is a danger of harm.

Conclusion

If hazardous energy is not appropriately managed workers doing regular machinery or process equipment maintenance may be badly hurt. It is why safety lockout tagout padlocks are used to turn off possible energy risks and avoid such mishaps.

To purchase the best lockout products as per OSHA standards contact the Lockout Supplier Safety House Loto.

You May Also Like: How to Ensure Worker’s Safety From Lockout Tagout Procedure?

You May Also Like: What is the Purpose of Lockout Tagout: Advantages & Disadvantages

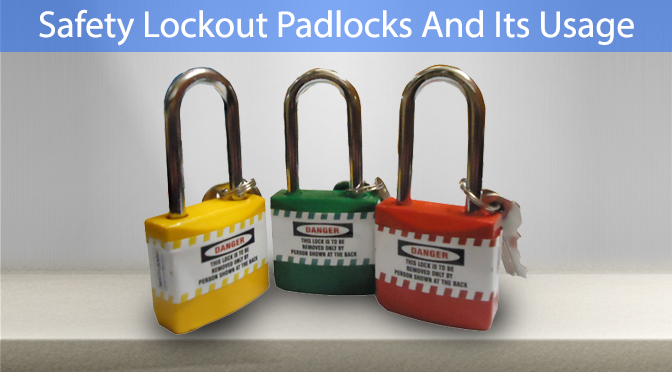

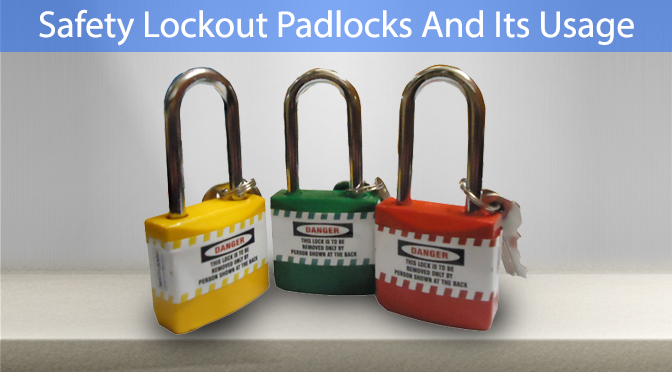

Safety Lockout Padlocks And Its Usage

Padlocks are little and transportable locks that are used for many thousand years to defend against the thieving, unauthorized entrance. within the terribly broadest sense of the word, a lock may be a device that keeps things valuables safe or restricts access to one thing that desires protection. These safety lockout padlocks are fitted to things like doors and cabinets and have 2 physically separate elements, One half is fitted to the frame and also the different part of the lock fits into an oblong hole within the door.

A Lockout padlock consists of a body, shackle, and protection mechanism. the everyday shackle may be a “U” formed loop of metal (round or sq. in cross-section) that encompasses what’s being secured by the padlock e.g. Chain. Generally, most padlock shackles either swing away or slide out of the padlock body once within the unfastened position. There are 2 basic styles of padlock protection mechanisms, integrated & standard. Integrated protection mechanisms directly have to interact with the padlock’s shackle with the tumblers whereas standard protection mechanisms don’t directly use the tumblers to lock the shackle. Padlocks with standard mechanisms are typically automatic, or automatic.

Here Are Some Usage Of Safety Lockout Padlocks-

- Keeping vehicles secure– we all love our vehicles and treat them like our family members, and nobody wants to get their tools or any part to be stolen by a thief. Companies like Safety house, one of the best lockout padlock manufacturers have just the solution that you need. We have a vast range of strong safety padlocks. It is one of the very traditional ways to keep your vehicles safe. The top-notch quality of the lock ensures the safety of the vehicle.

- Locking lockers at offices and fitness centres – people keep their important things in lockers like their purses, mobiles or other things, and places like office and gym where many people come and go makes it a less secure place. While being working we all want to be ensure that our personal belongings are safe and for that peace of mind a safety lockout padlock can help a lot.

- Protecting information for companies – in this modern world people are depend on computers be it business, financing, socialising or even dating, everything is being typed into the computer. All these high tech systems need to be protected by a more traditional safety measure, a good quality lockout padlocks will keep the intruders away from entering the premises in the first place.

Given all these usages of safety lockout padlocks, you must have known the importance of these padlocks due to their fantastic facilities. Safety House is an ISO certified company, one of the best manufacturers of lockout products in India. Our aim is customers satisfaction in all aspects.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- Osha lock

- Valve lockout

- Key box

Enquire Now