Lockout Kit Essentials for Different Industries: Tailoring Safety Solutions

Introduction

In industries where machinery and equipment pose significant safety risks, a well-organized lockout/tagout (LOTO) kit is crucial for ensuring worker safety. Lockout kits are essential tools that help prevent accidental machine start-ups during maintenance or repair activities. However, different industries have unique requirements, and tailoring lockout solutions to these specific needs is vital. Safety House Loto offers comprehensive lockout/tagout products designed to meet these diverse demands.

Why Lockout/Tagout Kits Are Important

Lockout/tagout kits play a pivotal role in protecting workers from hazardous energy sources during maintenance or service operations. By using a LOTO kit, you ensure that machines are properly shut down and cannot be accidentally reactivated, thus preventing injuries and fatalities. The effectiveness of these kits depends on their suitability for the specific machinery and environment in which they are used.

Tailoring Lockout Kits for Different Industries

1. Manufacturing

In manufacturing settings, lockout/tagout kits need to address various types of machinery, including presses, conveyors, and injection molding machines. Essential components of a manufacturing LOTO kit typically include:

- Padlocks: Durable and high-security lockout padlocks to lock out machinery.

- Hasps: Multi-lock hasps to accommodate multiple lockout points.

- Tags and Labels: Clear and durable tags to indicate that machinery is under maintenance.

2. Construction

Construction sites present unique challenges for lockout/tagout due to the variety of equipment and energy sources used. A construction-specific lockout kit should include:

- Lockout Devices for Electrical Panels: Devices to isolate electrical sources, such as circuit breaker lockouts.

- Valve Lockouts: For controlling the flow of hazardous substances through pipes and valves.

- Portable Lockout Kits: Easy-to-carry kits for use across different job sites.

3. Oil and Gas

The oil and gas industry requires robust lockout/tagout solutions due to the high-risk environment and complex machinery involved. A specialized lockout kit for this industry might include:

- High-Temperature Lockout Devices: To withstand extreme conditions.

- Pneumatic Lockouts: For isolating pneumatic energy sources.

- Custom Tags: To comply with industry-specific safety standards and regulations.

4. Utilities

Utility companies deal with large-scale electrical and mechanical systems that require comprehensive lockout/tagout solutions. Essential components for a utility lockout kit include:

- Electrical Lockout Devices: For isolating high-voltage circuits.

- Valve Lockout Devices: For controlling utility pipelines.

- Lockout Tags: To provide clear, informative warnings.

Key Considerations When Choosing a Lockout Kit

1. Compliance with Regulations

Ensure that your lockout kit meets the safety standards and regulations applicable to your industry. Compliance helps in avoiding legal issues and ensures worker safety.

2. Customization

Choose a lockout kit that can be customized to fit the specific needs of your equipment and work environment. A tailored kit ensures that all potential energy sources are properly addressed.

3. Quality and Durability

Invest in high-quality, durable lockout/tagout products that can withstand the rigors of your industry. Reliable products contribute to effective safety management and long-term cost savings.

Conclusion

Lockout/tagout kits are essential for maintaining a safe working environment across various industries. Tailoring these kits to the specific needs of your industry ensures that all potential hazards are effectively managed. Safety House Loto provides a range of lockout tagout products designed to meet the unique requirements of different sectors. By investing in a customized lockout kit, you protect your workforce, comply with safety regulations, and enhance overall operational efficiency.

Lockout Kit Maintenance: Tips for Keeping Your Tools in Top Shape

Essential Tips for Maintaining Your Lockout Kit

Introduction:

A lockout kit serves as a cornerstone of safety protocols in industrial environments, providing essential tools for controlling hazardous energy sources during maintenance or repair tasks. However, ensuring the effectiveness of these kits requires regular maintenance and upkeep. In this article, we’ll explore the importance of lockout kit maintenance and provide valuable tips for keeping your tools in top shape, enhancing workplace safety and compliance.

Understanding Lockout Kits:

Before delving into maintenance tips, let’s first understand what comprises a lockout kit. Typically, a lockout kit contains a variety of devices and accessories designed to isolate energy sources and prevent the accidental or unauthorized startup of machinery or equipment. Common components include padlocks, lockout hasps, tags, circuit breaker lockouts, valve lockouts, and other specialized devices tailored to different types of energy sources.

The Importance of Lockout Kit Maintenance:

Lockout kit maintenance is vital for ensuring the reliability and effectiveness of safety measures in the workplace. Regular upkeep helps identify and address issues such as damaged or worn-out components, ensuring that lockout devices function as intended when needed. By maintaining lockout kits in optimal condition, businesses can minimize the risk of accidents, protect workers, and maintain compliance with regulatory standards.

Tips for Lockout Kit Maintenance:

- Regular Inspections: Conduct periodic inspections of lockout kits to check for signs of damage, wear, or corrosion. Inspect each component thoroughly, paying attention to padlocks, hasps, tags, and lockout devices for any defects or malfunctioning parts.

- Replace Worn-Out Components: Replace any worn-out or damaged components promptly to ensure the integrity of the lockout kit. This includes replacing padlocks with broken shackles, worn-out tags, or damaged lockout devices to maintain effectiveness and reliability.

- Clean and Lubricate: Clean lockout devices regularly to remove dirt, debris, or contaminants that may impair their functionality. Apply lubricants to moving parts such as hinges and locking mechanisms to ensure smooth operation and longevity.

- Store Properly: Proper storage is essential to prevent damage and prolong the lifespan of lockout kits. Store kits in designated areas away from harsh environmental conditions, extreme temperatures, moisture, or direct sunlight.

- Update and Expand: Periodically review and update lockout kits to ensure they remain relevant and effective for the equipment and energy sources present in the workplace. Consider expanding kits to accommodate new machinery or equipment additions.

- Employee Training: Provide comprehensive training to employees on proper lockout kit maintenance procedures. Educate workers on the importance of inspecting, cleaning, and replacing components as part of their safety responsibilities.

- Document Maintenance Activities: Maintain detailed records of lockout kit maintenance activities, including inspection dates, component replacements, and any issues identified and addressed. Documentation helps track maintenance history and ensures accountability.

- Seek Professional Assistance: If unsure about maintenance procedures or encountering complex issues with lockout kits, seek assistance from qualified professionals or manufacturers for guidance and support.

Conclusion:

Lockout kit maintenance is essential for ensuring the effectiveness of safety measures in industrial environments. By following the tips outlined above, businesses can keep their lockout kits in top shape, enhancing workplace safety, minimizing the risk of accidents, and maintaining compliance with regulatory standards. Remember, proactive maintenance is key to safeguarding workers and promoting a culture of safety in the workplace.

The Ultimate Guide to Lockout Kits: Choosing, Implementing, and Enhancing Safety Measures

Lockout kits, also known as LOTO kits, are an essential component of workplace safety. These kits provide workers with the necessary tools and equipment to isolate machinery or equipment from its energy source during maintenance or repair work. Failure to implement proper lockout procedures can result in serious injuries or even fatal accidents. In this ultimate guide, we’ll explore the different types of lockout kits available on the market today and discuss what you need to look for when choosing one for your business. We’ll also cover how to implement a lockout kit effectively and enhance overall safety measures in your workplace. So let’s dive in!

What Is A Lockout Kit?

A lockout kit, also known as a LOTO kit, is a collection of tools and equipment designed to help workers isolate machinery or equipment from its energy source. Lockout kits typically consist of padlocks, hasps, tags, circuit breakers, and other safety devices that prevent the accidental release of hazardous energy.

When using a lockout kit, workers are required to follow specific procedures before performing maintenance or repair work on the equipment. These procedures involve isolating the energy source and ensuring that it cannot be re-energized until work is completed.

Lockout kits can come in various sizes and configurations depending on the type of machinery or equipment being serviced. Some kits may include specialized devices such as valve lockouts or electrical disconnects for specific applications.

Implementing proper lockout/tag-out procedures with a lockout kit helps ensure worker safety by preventing accidents caused by unexpected energization during servicing activities.

The Different Types Of Lockout Kits

Lockout kits come in various forms to cater to different industries and applications. The types of lockout kits that are available include electrical, mechanical, pneumatic, hydraulic, and combination lockout kits.

Electrical lockout kits are designed to prevent the accidental or unauthorized operation of electrical equipment during maintenance or repair work.

Mechanical lockout kits contain devices such as lockout padlocks and loto hasps which can be used to secure machinery with moving parts.

Pneumatic lockout kits prevent compressed air from being released accidentally during servicing procedures on pneumatically operated machines.

Hydraulic lockout kits similarly protect against any hydraulic energy that could potentially harm workers when working on hydraulic-powered systems.

Combination lockout kits may include a mix of devices from each category depending on the specific needs of a workplace.

When choosing a type of kit, it is important to ensure that it meets all relevant safety standards for your industry and application.

Pros and Cons Of a Lockout Kit

A lockout kit is an essential tool for any workplace that uses heavy machinery or equipment. It enables workers to safely shut down and isolate the energy source of a machine, ensuring that no one can accidentally start it up again while repairs are being made.

One of the major advantages of a lockout kit is increased safety. By making sure machinery cannot be turned on during maintenance or repairs, employees are protected from potentially dangerous accidents. Another benefit is compliance with OSHA regulations; using a lockout kit demonstrates a commitment to worker safety, which can prevent costly fines and lawsuits.

However, there are some downsides to using a lockout kit. One potential issue is decreased productivity, as shutting down machinery takes time away from production. Additionally, if not used correctly or consistently by all employees, a lockout system could lead to confusion and mistakes.

The benefits of implementing a reliable lockout system far outweigh any potential drawbacks. With proper training and usage guidelines in place, businesses can ensure their workers’ safety while maintaining efficient operations.

What to Look for When Choosing a Lockout Kit?

When it comes to choosing the right lockout kit for your workplace, there are several factors that you should consider. First and foremost, you must ensure that the kit meets all relevant safety standards and regulations.

Another important consideration is the size of your facility. If you have a large facility with many different types of machinery and equipment, you may need a more comprehensive lockout kit that includes a wide range of devices and tools.

It’s also important to choose a lockout kit that is easy to use and understand. Look for kits with clear instructions and diagrams so that employees can quickly learn how to properly secure equipment during maintenance or repair work.

Durability is also crucial when selecting a lockout kit. Your chosen kit should be able to withstand frequent use in harsh industrial environments without breaking down or losing effectiveness over time.

Consider purchasing from reputable manufacturers who offer good quality customer service, warranties, and technical support. This ensures that any issues or questions will be addressed promptly if they arise in the future.

Implementing a Lockout Kit

Implementing a lockout kit is an essential step in ensuring the safety of workers who operate machinery and equipment. The process involves creating standard procedures to isolate energy sources before performing maintenance or repairs.

The first step in implementing a lockout kit is to identify all possible energy sources that could cause harm. This includes electrical, hydraulic, mechanical, pneumatic and chemical energy sources. Once identified, each energy source must be isolated using the appropriate locks and tags from the kit.

It’s crucial to train employees on how to use lockout kits correctly as part of their job responsibilities. This training should emphasize the importance of following procedures strictly for every machine they work with.

After implementing a lockout procedure, it’s essential to conduct regular audits and inspections to ensure employee and management compliance. These assessments help identify any gaps in implementation so that corrective measures can be taken before accidents occur.

Implementing a lockout kit requires careful identification of potential hazards followed by strict procedural guidelines for isolating those hazards through locking out all forms of hazardous energy sources.

This ensures worker safety when maintaining or repairing machines while also reducing risks associated with such equipment operations.

Enhancing Safety Measures with a Lockout Kit

Lockout kits are a valuable tool for ensuring the safety of employees who work in settings where hazardous energy sources are present. However, simply having a lockout kit is not enough to guarantee workplace safety. It’s crucial to implement proper procedures and protocols to ensure that the kits are being used correctly.

One way to enhance safety measures with a lockout kit is by creating written procedures outlining how and when the equipment should be used. These procedures should include information on which machines or equipment require locking out, as well as specific steps for using the lockout kit properly.

Another important step in enhancing safety measures with a lockout kit is training employees on proper usage and maintenance of the equipment. This includes teaching them about different types of energy sources, identifying potential hazards, and demonstrating how to use each component of the kit.

It’s also essential to regularly inspect all lockout devices and replace any damaged or worn-out components promptly. Keeping an inventory of your company’s current supplies can help you stay ahead of future needs so that you’re never caught without necessary items.

It’s always wise to review your LOTO program periodically; this ensures that everything continues running smoothly while addressing changing conditions or needs within individual departments. With careful planning and attention-to-detail during implementation, businesses can successfully improve their overall level of workplace safety through comprehensive LOTO programs bolstered with reliable tools such as quality Lock Out/Tag Out (LOTO) Kits.

Conclusion

Lockout kits are an indispensable tool for keeping employees safe while working on potentially dangerous machinery or equipment. By using lockout kits, employers can effectively prevent accidents caused by unexpected start-ups and releases of stored energy.

When choosing a lockout kit, it’s important to consider the specific needs of your workplace and ensure that the kit includes all necessary components. Once implemented, it’s crucial to train employees on how to properly use the kit as part of their safety training.

Enhancing safety measures with a lockout kit doesn’t have to be complicated or expensive. By following best practices and regularly reviewing your procedures, you can create a safer work environment for everyone involved.

Investing in high-quality lockout kits is essential for any organization looking to prioritize employee safety. Taking the time to choose the right kit and properly implement its usage will go a long way towards preventing accidents in your workplace.

Checkout Our Popular Products:

- Osha lock

- Lockout station

- Scaffold Tag

- MCB Lockout

Everything You Need to Know About the Types of Circuit Breaker Lockout

You’ve probably seen Miniature Circuit Breaker Lockout (MCBs) in your home. When you turn on or off an appliance, the power of the whole floor is impacted. It is because the MCB Lockout is linked to all the circuits on the floor, and shutting off the main switch turns out the lights.

However, a circuit breaker’s primary function is to safeguard the device and humans from harmful electrical shocks and failures. Circuit breakers, in other words, are devices that prevent electrical short-circuits and sustain power flow.

Do you know anything about the circuit breaker lockout device? Do you want to discover its benefits and drawbacks? Then this article will assist you in comprehending several types of productive effects. Let’s have a look at circuit breakers.

What exactly is a circuit breaker?

Circuit breaker trips cut electricity to the load and prevent damage. Industries, buildings, commercial complexes, and hotels rely heavily on circuit breakers to convert between different modes of operation.

Why is a circuit breaker required?

Several unusual circumstances in our electrical system can harm the circuit and its components. These are referred to as ‘FAULTS.’ Furthermore, faults are classified as follows:

- Overload

- Earth Short Circuit

Besides, we must safeguard our system from the errors above to maintain our electrical components and system safe. It necessitates the use of a circuit breaker.

Types of Circuit Breaker Lockout

Circuit breakers are primarily classified according to voltage application:

1) Circuit Breaker with Low Voltage

2) Circuit Breakers for Medium Voltage

3) Circuit Breakers SF6/VACUUM

4) Circuit Breakers for High Voltage

How do they work?

Circuit breakers are built to tolerate a transient surge in amperage over their rated capability, allowing fan motors or compressors to operate. Moreover, a Time/Amperage or “Trip” curve indicates the period they can let this inrush against the actual amperage capacity they can tolerate during that time.

Read More: Circuit Breaker Lockout Device: Advantages and Disadvantages

Furthermore, depending on the breaker’s design and function, it may take up to 15 times the expected load and trip anywhere between milliseconds and 2-3 seconds later.

Breakers are classified into three positions:

- Closed circuit — on

- A trip—open circuit signals a problem as well.

- Off—short circuit

Conclusion

This overview of panelboards and several kinds of circuit breakers, their construction and operation, and fundamental electrical safety protocols is an excellent place to start if you’re new to the sector. Hence, check out Safety House blogs for a more in-depth look at these topics. In the nation, there are various lockout-Tagout service providers.

However, not all of them provide their consumers with high-quality goods. Safety House is a trustworthy business that has served its many satisfied consumers for years. Pick the best Lockout Tagout Products and Loto service provider for your company by carefully considering your requirements.

Top Selling Safety House Lockout Tagout Devices

> Key Box

> Valve Lockout

> Osha Lock

Related Post To Read: How to Ensure Worker’s Safety From Lockout Tagout Procedure?

Related Post To Read: Lockout Tagout Advantages & Disadvantages

How To Find The Lockout Padlocks As Per OSHA Standards?

When it comes to the potential of one employee mistakenly restarting a piece of equipment that another employee is working on, the employee’s sole safeguard is their lockout lock. Employees must learn how to operate their locks correctly and never give out their lock or key to guarantee complete control.

OSHA’s Lockout Tagout Regulations (1910.147)

Lockout Tagout devices must be robust, standardised, significant, and recognisable, according to OSHA Standard 29 CFR 1910.147.

- To achieve OSHA regulations, Lockout Safety Padlocks must meet the following requirements:

- Be able to tolerate long-term exposure to harsh weather conditions and be chemically resistant.

- Have a consistent color, shape, or size across the institution.

- Non-reusable, hand-attachable, self-locking, and non-releasable with a minimum unlocking strength.

- Use the tools to identify people and other recognizable data such as padlock numbers, metal marking, logos, department designations, etc.

Read more: Elements Of OSHA’s Lockout-Tagout Standard

A lockout programme consists of three key components

- Written Procedures: These protocols tell lockout participants what to do and when. They also outline the procedures for shutting down, isolating, and imposing and removing lockout. Such methods are only required for machines with two or more energy sources.

You should clearly state the following points:

- Specific machinery and their shutdown/isolation procedures

- Location of lockout mechanisms

- How to de-energize stored energy

- How isolation must confirm.

- Training Programs: Training is required for two types of employees: authorised and affected. Authorised employees maintain and service machines and are qualified to control hazardous energies. In contrast, affected employees work near the machines/equipment being serviced or repaired under lockout and must understand the hazards.

- Periodic Audits: Periodic audits ensure that energy control operations are still being done correctly, that employees are following protocols, and that they know their commitments.

What You Should Look In Lockout Padlocks & Its Benefits

Lockout Padlocks prevent mishaps by preventing equipment from being mistakenly turned on. This also prevents damage to the equipment and makes the workplace safer for everyone. Moreover, lockout Osha Lock is available in a variety of colors and is very durable, making them an excellent investment for any company.

As previously noted, are an essential component of any safety program. Workers may use Lockout Padlocks to ensure that machinery or equipment is not switched on while doing maintenance and repairs.

Safety house Lockout Padlocks may also be used to protect electrical panels, valves, and other potentially dangerous items. You may assist avoid accidents and injuries by clearly identifying dangers and shutting them out.

- Lockout padlocks are color-coded to make them easier to identify, and each Lockout Padlock may be allocated to a single employee. This guarantees that the equipment is only accessible to authorized employees.

- Padlocks, when utilized appropriately, may help make your workplace safer for everyone.

- It is a low-cost and easy approach to safeguarding the safety of your employees. Among the advantages are:

- Preventing mishaps by preventing equipment from being mistakenly turned on during maintenance.

- Disabling damaged equipment also protects it from additional harm.

- Lockout Padlocks are also useful for determining who has disabled the equipment since they are generally color-coded.

- This is significant because it makes everyone’s workplace safer.

Lockout Padlocks and Lockout Kits are a simple and efficient approach to increasing workplace safety and should be utilized wherever equipment is a danger of harm.

Conclusion

If hazardous energy is not appropriately managed workers doing regular machinery or process equipment maintenance may be badly hurt. It is why safety lockout tagout padlocks are used to turn off possible energy risks and avoid such mishaps.

To purchase the best lockout products as per OSHA standards contact the Lockout Supplier Safety House Loto.

You May Also Like: How to Ensure Worker’s Safety From Lockout Tagout Procedure?

You May Also Like: What is the Purpose of Lockout Tagout: Advantages & Disadvantages

How Many Types of Group Lockout Box?

Loto Group Box physically locks the complete system such as the machine, equipment, and even process in the safe mode. Lockout and Tagout is the Control of Hazardous Energy which involves with isolation of energy from the system.

What is the Benefit of Group Lockout Boxes?

The Group Lockout Boxes are storage devices used to capture keys to make effective lockout of large equipment. Moreover, all the lockout is enabled with a single padlock to secure the equipment.

Lockout devices offer the best way to easily secure the machinery equipment. These have circuit breaker lockout along with the electrical plug lockout device.

The Use of Group Lockout Box keeps all the keys safely and is enabled with the safe key storage facility. All the lockout points on Loto Box are also easily accessible.

Types of Loto Group Lockout Box

These are storage devices that can be used to capture keys for effective lockout of equipment. These lockout tagout products are certified raw materials used, so they would enhance the functionality. The lockout point on equipment is secured with a single padlock.

Master Lock Group Lock Boxes S600 Series

Normally, the Master Lock Group Lock Boxes S600 Series have 430-grade stainless steel. These can easily withstand the harshest environments as they have a tough structure with superior design features.

It makes lock boxes stronger and easier to use. The Master Lock Group Lock Boxes S600 Series has a stackable design suitable for storage. It also helps with making quick transporting of multiple boxes.

Portable Red Group Lockout Box

The Master Lock Portable Red Group Lockout Boxes are suitable for capturing the keys from lockout points. It is easier to secure a lockout point even with a single piece of equipment.

Group Boxes and Loto Kits Capture keys from lockout points and easily place them in the lockbox. The Lockout Boxes are suitable for the padlock or other fixed devices.

However, it offers flexibility for the lock. This easy-to-grip is perfect for wide areas like machinery, the safety of workers, and other equipment. Read More: Advantages & Disadvantages of Lockout Tagout

Lockout Safety Heavy Duty Lockout Box

The Lockout Safety Heavy Duty Safety Lockout Boxes provide durability as well as flexibility, ensuring better access for all parties.

Furthermore, safety Lockout Boxes are also perfect for group lockout situations. All the keys have identification tags with multiple boxes under control.

Lockout Safety Portable Red Group Box

The Group Lockout Box model ensures the machine or keys in the machine are fully secure. Moreover, it accommodates up to 7 safety locks with easy to carry around. Group Lockout Box offers the best way to lock all the parts in the machine.

You May Also Like: What is an Electrical Panel Lockout Box and Its Uses?

You May Also Like: What is the Purpose of Lockout Tagout: Advantages & Disadvantages

What are Lockout Key Box and Its Uses?

The lockout key box is the best storage device that is effectively useful to store keys for an effective lockout for huge equipment. One can protect the lockout point available on the equipment with a single padlock.

It can ensure that other technicians or departments could never remove keys, documentation, permits, or anything else before the parties open individual locks.

Safety Impact of lockout key box

Here workers can keep their keys in this box, and then only authorized employees have access to touch it. Employees can remove the personal padlock from the lock box when the work is completed and free the keys.

Read More: How to Ensure Worker’s Safety From Lockout Tagout Procedure?

However, the lockout key box can ensure that keys never be accessed until the final lock is removed.

A lockout key box is the safest approach enforced by putting the suitable lockout devices into energy-isolating devices based on the established procedure.

Furthermore, it will ensure that no one can operate the controlled equipment and energy-isolating device until removing the lockout device.

Uses of lockout key box

Lockout key boxes are handy for safe key storage and the best place for holding keys. Lockout products are highly useful in protecting employees from dangerous energy sources on equipment and machines during maintenance service.

Additionally, most industrial accidents are due to the unexpected start-up of equipment and machines or the uncontrolled release of energy. Therefore, it is better to use a high-quality lockout key box without hesitation to stop issues.

The best energy control program

Best Lockout Kit is effectively suitable for various energy control programs. An excellent energy control program contains:

- Durable, reliable, and high-quality lockout products to cover all electrical and mechanical applications

- A specially designed lockout solution can help implement and develop the control program effectively

- Documented, tailored, and appropriated lockout procedures are all OSHA complaints

- Conduct the lockout audit regularly to ensure safety in the workplace

Benefits of lockout key box

You can explore more benefits after using lockout kits. Check out below to know the benefits:

- Protect employees from accidents and hazards

- Shows top management concern over the employee safety

- Protects machine, equipment, and workplace from severe damage and reduces downtime

- Helpful in meeting the key box compliance without any issues

- Builds trust and self-confidence in all employees

Final verdict

You have now explored the lockout key box and its uses from the scenario mentioned above. You can contact the leading experts and manufacturers if you want quality lockout key cabinets.

Moreover, safety House is the leading manufacturer and lockout supplier of lockout tagout products. The lockout key boxes are powder coated, highly durable, and have stainless steel handles.

You May Also Like: What Are The 6 Steps Of Lockout Tagout Programs?

You May Also Like: Safety Precautions While Working Around the Lockout/Tagout Equipment

Safety Lockout Hasp: Types, Benefits, and Its Uses

Lockout hasps are widely used for safety procedures because of their unique functionalities. Of course, it will develop a good one and be able to adapt to multi-person lockout. They ensure a good outcome and establish a new solution for choosing branded safety lockout hasp and its uses.

However, the safety lockout has permitted us to do more completely risk-free things. It works effectively and can adapt to unlocks on the padlock from the hasp.

Types of Lockout Hasp

There are lots of safety lockout hasp available. On the other hand, the lockout provides distinct solutions and carries out energy sources. They assure good one and adapt on switched on locked out with tagout. It is mentioned by focusing on loto hasp with a date and name.

They are attached to get hasps and efficiently take successful outcomes for your lockout program. It will develop colored-coded by depends on the engineer’s choice and development.

- Snap-On Hasp Style

- Standard Hasp Style

- Scissor-Action Hasp Style

- Heavy-Duty Hasp Style

- Dual-End Hasp Style

- Loto Color Hasp

- Mini Hasp Style

- Safety Hasp Style

What are the Benefits of Lockout Hasp?

It provides a clear-cut solution for lockout, and hasp should take a good choice forever. The lockout hasp should combine well and ensure a good outcome for showing possible choices.

Strong and durable plastics made

On the other hand, the safety lockout hasp should combine with individual needs. The strong and durable industrial haps can give good outcomes and restores them quickly. Moreover, it will be aligned to get the carrying maintenance forever.

The padlocks and others should combine with lockout hasp by focusing on restored options. Hasp comes forward showing more options and enjoying strong plastics depending on the requirements. The hasp lockout must develop a good one and explore maintenance properly done with a major solution.

Ensures low maintenance

Likewise, the safety lockout hasp should come with one energy source. It gives more usability and can adapt to each person to create a long-lasting solution. The lockout kit and group box with hasps adapt to focusing on high-quality collections that depend on the requirements.

Loto hasps provide a good one and explore energy to retain on the padlocks that have been removed so far. Moreover, this device ensures a clear-cut solution and adapts to low-maintenance work forever.

Changes in simple cable fit

The safety lockout hasp and its uses must develop a good one and adapts on warning. Hasp will explore a lot and is mainly applicable to notice changes in removing padlocks and others. Thus, a simple cable tie to a padlock with unique functionalities.

Moreover, it will control mainly by focusing on high-end results. It will update changes in the simple cable and fit, tampering, and others. So, Lockout India carries out more things and is mainly suitable for lockout tags for your communication needs.

Read More: What is the Purpose of Lockout Tagout: Advantages & Disadvantages

Read More: What Are The Usage Of Electrical Plug Lockouts?

Read More: How To Use Lockout (Loto) Kit?

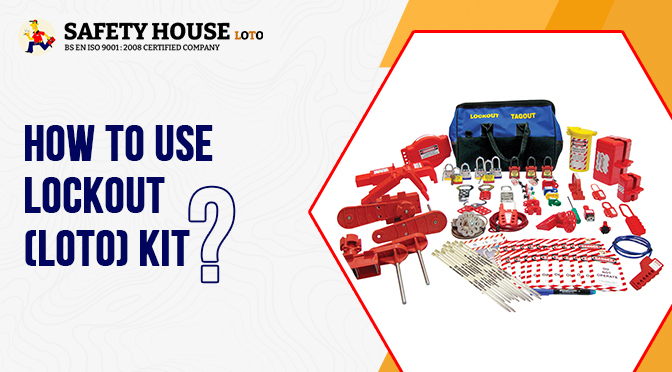

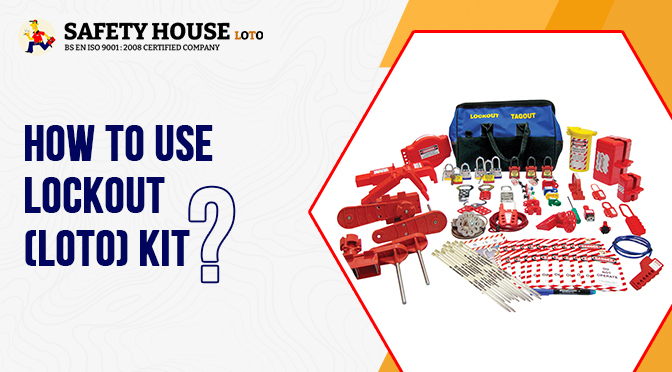

How To Use Lockout (Loto) Kit?

The lockout kit is the bunch of gear accessed for performing lockout techniques on the hazardous hardware. The use of lockout kit becomes unavoidable in the industrial area where safety should be observed. Loto means lockout tagout, which is the necessary safety procedure for protecting employees and workers around the equipment and machinery they operate, maintain, and service.

It is also a vital OSHA-inspection focus and remains one of the most cited violations for the general industry. Moreover, lockout Tagout is the procedure used to ensure that equipment/machinery is shut down and inoperable until the completion of repair or maintenance work.

A company should educate their employees on how to use loto kit properly to keep themselves safe from machinery that could injure or kill them when not managed correctly. Continue reading to know the major Loto Kit uses and how to use the kit properly to ensure workers’ safety!

Things to know about lockout kit

The lockout kit is accessed on electrical gear, hardware, and plumbing frameworks to minimize the likelihood of wounds from unforeseen happenings. Furthermore, this kit accompanies several types of locks and recognizable proof tags. The use of lockout kit renders workers a strategy for referring to data about the perils relevant to the locked-out hardware.

Moreover, the loto kit uses are extensive because it has lots of safety tools and equipment such as lockout padlocks and valve lockout devices. It is extremely useful for different situations. Manufacturers provide basic to advanced lockout kits, but you must buy the right kit suitable for your work environment.

But, remember that the major use of lockout kit is to protect the workers of the industry when accessing dangerous and harmful machines. In addition, this kit minimizes the inadvertent activity of machines under maintenance.

How to use the lockout kit?

Are you thinking about how to use lockout tagout kit? If yes, you should become aware of the tools and equipment available in the kit. Knowing the usage of every tool in the kit is important to enjoy its benefits completely.

- The lockout tagout box kit also contains the equipment that needs to be worn to minimize hazards and other safety tools accessed on the machinery.

- The loto process lets energy be removed from the situation and prevents all unintended motion and energy discharge.

- Keep in mind that locking and tagging out the machine does not prevent hazards completely.

- Follow the employer’s safety guidelines and caution all the time. Knowing how to use lockout kit properly will help employees sort out complicated situations without any damage.

If you want to access the best Loto kit, Key Box, and other safety house products, you should engage with a reliable Loto kit manufacturer like us. The professional will explain the loto kit uses and the procedure to utilize it properly.

Top Danger Lockout Tags and Caution Labels

Many companies place a high value on maintaining a flawless locking mechanism to safeguard their employees and outsiders. These safety Danger Lockout Tags alert people to potential dangers if a machine or piece of equipment is turned on.

For businesses to identify the energy source and who is using the machine or equipment, lockout tags must be used. It serves as both a visible reminder and a physical barrier for safety reasons.

As an example of an application related to energy release, the tag may be used in conjunction with switches such as Blocks Disconnect. The Lockout Tagout Products rely heavily on tags. Lockout tags of lockout India safety house provide information about the lockout state and may identify the individual repairing it.

- The ability to withstand the conditions in which they are used

- Standardization and differentiation from other tags are key requirements for labels.

- Include specific cautions and directions.

- Securely fastened using a 50 lb pull-force-resistant, non-reusable self-locking mechanism

Top Best Danger Lockout Tags List

Lockout tags are widely available nowadays to safeguard the machine and its components; here are the top danger lockout tags. Consider many kinds of safety lockout devices and choose the most appropriate one for your business to optimize security.

Danger Caution tag

Caution tags are used when there is a low risk of death or serious injury, but there is a possible danger that may not be immediately apparent.

Do to operate tag is used by companies to ensure the safety of their workers and staff. Moreover, personnel should be informed and warned before operating the machinery or equipment to prevent accidents.

Lockout tag for machinery

This huge risk may avoid with an efficient lockout procedure. Furthermore, using the equipment lockout tag of Loto Kit is the best way to keep yourself safe while keeping the isolated energy device in the appropriate place.

The fire inspection tag

Using a fire inspection tag is the easiest way to keep track of the extinguisher’s current state. In a fire, having well-maintained extinguishers on hand is essential. Furthermore, sometimes, fire inspection tags are also used on Valve Lockout to ensure the safety of the worker.

Photo tag with a lockout

Industries use the lockout picture tag to add a photo to their lockout and safety programs. Moreover, this danger lockout tag comes with a transparent pocket where you can put your employee’s picture or ID to give safety and accident prevention a personal touch.

Scaffold tag

Employees who work on scaffolds rely on Scaffold Tags to keep themselves and their colleagues safe with the best danger lockout tags. Such things are used by businesses to protect the health and safety of their personnel. In addition, it keeps track of a variety of specifics, such as restrictions, limitations, and safety data related to a certain scaffold.

Conclusion

Business owners and peoples use the finest expertise to pick up lockout tags for industrial safety and ensure total protection. Our Safety House Loto is the best Lockout Supplier company that helps to maintain safety for your business.

You Might Also Like: Types of Lockout Tags & Its Usage for Industrial Safety

You Might Also Like: What is a Lockout Kit And Why is it Used For?

You Might Also Like: Safety House Loto Products For Safe Work Environment