Lockout Hasps for Small Businesses: Affordable Safety Solutions

The small business sector is faced with unique challenges in terms of safety for the employees. Due to the unavailability of funds, small teams, and diverse responsibilities, developing safety measures should be used as the base guidelines for hire affordableand efficient. In that sense, Safety House LOTO has been able to come to their rescue by supplying Lockout Hasps to ensure workplace safety in these very demanding, machinery and electric equipment-driven operational environments.

What Are Lockout Hasps?

Lockout Hasps are safety devices designed to lock out energy sources during equipment maintenance or repair. These devices allow multiple workers to secure a machine or electrical panel by attaching their personal padlocks to the hasp. This ensures that the equipment remains inoperative until all locks are removed, safeguarding workers from accidental startups or energy release.

Why Are Lockout Hasp Essential for Small Businesses?

Small businesses are often on tight budgets and cannot take risks with workplace accidents. Amy form of injury can lead to financial losses, legal liabilities, and downtime, which can really cripple the operation. Lockout Tagout (LOTO) products, including Lockout Hasps, are a worthwhile shield in that they are affordable and simple solutions to avoid any such catastrophe by locking out dangerous machinery or process.

1. Cost-Effective Safety

For small businesses, affordability is key. Lockout Hasp are relatively inexpensive compared to other safety measures. Their durable design and reusability make them a one-time investment with long-term benefits.

2. Versatility Across Industries

Whether you run a small manufacturing unit, a workshop, or a retail outlet with basic electrical systems, Lockout Hasp can be adapted to various equipment types. They are particularly useful for machines with multiple energy sources, where multiple workers need to secure the system.

3. Compliance with Safety Regulations

Adhering to workplace safety regulations is essential for businesses of all sizes. LOTO systems, including Lockout Hasp, help small businesses comply with Occupational Safety and Health Administration (OSHA) guidelines or similar regulatory requirements, reducing the risk of penalties.

How Lockout Hasps Work

The simplicity of Lockout Hasps is one of their strongest features. Here’s how they function:

- Placement: The hasp is placed through the energy isolation point, such as a switch or valve.

- Locking: Each worker involved in the maintenance attaches their personal lock to the hasp.

- Team Safety: The machine cannot be reactivated until every lock is removed, ensuring collective safety.

This collaborative approach to safety is particularly beneficial in workplaces with multiple employees handling the same equipment.

Types of Lockout Hasps

Small businesses can choose from a range of Lockout Hasps to suit their specific needs:

1. Standard Lockout Hasp

These are basic hasps made of durable materials, suitable for general-purpose use.

2. Insulated Lockout Hasp

Ideal for electrical applications, these hasps are coated with non-conductive materials to enhance worker safety.

3. Heavy-Duty Lockout Hasp

For machinery with high energy levels or challenging environments, heavy-duty hasps provide added durability and reliability.

Benefits of Using Lockout Hasps

1. Enhanced Worker Safety

By preventing unauthorized access to equipment, Lockout Hasps reduce the risk of accidents caused by unexpected startups.

2. Promotes Accountability

Each worker uses their lock, ensuring personal responsibility for safety during maintenance.

3. Simplified Processes

The ease of use makes Lockout Hasp accessible for small businesses, even with limited training resources.

4. Long-Term Durability

Built to withstand tough conditions, Lockout Hasps offer long-lasting protection, making them a cost-effective choice for safety.

Integrating Lockout Hasps with Lockout Tagout Products

While Lockout Hasps are critical, their effectiveness is amplified when integrated into a comprehensive Lockout Tagout system. Other essential LOTO products include:

- Padlocks: Used in conjunction with hasps to secure energy sources.

- Tags: Provide clear communication about the locked-out equipment, including who locked it and why.

- Valve and Circuit Breaker Locks: Specialized devices for isolating specific types of energy sources.

Small businesses can create a robust safety framework by combining these products, ensuring a safer workplace.

Choosing the Right Lockout Hasps for Your Business

When selecting Lockout Hasps, small businesses should consider:

- Material: Opt for durable materials like steel or non-conductive coatings, depending on the application.

- Size and Design: Ensure compatibility with your equipment’s energy isolation points.

- Ease of Use: Choose hasps that are simple to implement, especially if your team is new to LOTO practices.

Conclusion

To small businesses, safety does not mean spending a lot. Lockout Hasps provide an effective and affordable answer to workplace accidents and safety regulations compliance. Their affordability, versatility, and durability make them an indispensable item you may find in any Lockout Tagout system.

Quality LOTO products protect employees while cutting down on downtime, allowing a culture of safety to develop in businesses. Be they small workshops or a small enterprise that is looking to develop, the inclusion of the Lockout Hasps will serve as a forward step towards a safe and high-performing workplace.

How Does Lockout Hasp Prevent You From Accidents?

Lockout hasps are designed to prevent you from accidents. Before we go into the details of how safety lockout products work to prevent accidents, let us understand the term.

When more than one employee is involved in a lockout:tagout operation, a lockout hasp plays an important role. As employees work in a group on the same energy source, the hasps allow multiple padlocks to be utilised when isolating one energy source. The lockout hasp is placed through a latch on the machinery. Each employee who is carrying out service or maintenance work attaches his padlock through any one of the six openings within the lockout hasp. All of the padlocks are then locked.

Lockout hasp has a zinc plated steel jaw so that they can pull at least 50 pounds. Sometimes, strong and spark resistant aluminium is also used in Jaws if required. Some are available with a nonconductive, red vinyl handle coating to improve the grip. It also protects the tool from scratching.

To maximise their use, Lockout Hasp also has the sign of “Danger” and “Do not Operate”. This can make them available to be used as a lockout device as well as a tag in one central unit. This ensures that each worker is working safely during the lockout operation. Various colour options in lockout hasps make them ideal for group lockout. Some lockout hasps are dual sided to lock out more than one of the equipment together.

How Lockout/Tagout Safety Can Prevent Accidents?

Working with machines requires great safety. Lockout Hasps can prevent accidents in the following way:

- Lockout Hasp does not let machines or equipment start unexpectedly. Machines may release stored energy or start by mistake which can cause harmful injuries. Safety lockout tagout products are of great use to prevent these situations.

- These lockout hasps provide efficient multi-person lockout. This means that Multiple padlocks can be applied to Loto Hasp, allowing an energy source to be isolated by more than one worker. This will ensure complete lockout and the machine can’t be operated until each worker unlocks their padlock from the hasp.

Although safety lockout products are mostly used in manufacturing companies, they can be also used in office buildings, healthcare facilities, construction sites, projects, hotels, ships, offshore installations, etc.

The good news is – it’s not an expensive proposition. Implementing an effective lockout/tagout program doesn’t require a heavy investment of time or money.

Safety House Is an ISO Certified company which manufactures products for Energy Isolation and you can trust their products for best safety.

Checkout our other safety products:

- Scaffold Tag

- Valve Lockout

- Key Box

How To Find The Lockout Padlocks As Per OSHA Standards?

When it comes to the potential of one employee mistakenly restarting a piece of equipment that another employee is working on, the employee’s sole safeguard is their lockout lock. Employees must learn how to operate their locks correctly and never give out their lock or key to guarantee complete control.

OSHA’s Lockout Tagout Regulations (1910.147)

Lockout Tagout devices must be robust, standardised, significant, and recognisable, according to OSHA Standard 29 CFR 1910.147.

- To achieve OSHA regulations, Lockout Safety Padlocks must meet the following requirements:

- Be able to tolerate long-term exposure to harsh weather conditions and be chemically resistant.

- Have a consistent color, shape, or size across the institution.

- Non-reusable, hand-attachable, self-locking, and non-releasable with a minimum unlocking strength.

- Use the tools to identify people and other recognizable data such as padlock numbers, metal marking, logos, department designations, etc.

Read more: Elements Of OSHA’s Lockout-Tagout Standard

A lockout programme consists of three key components

- Written Procedures: These protocols tell lockout participants what to do and when. They also outline the procedures for shutting down, isolating, and imposing and removing lockout. Such methods are only required for machines with two or more energy sources.

You should clearly state the following points:

- Specific machinery and their shutdown/isolation procedures

- Location of lockout mechanisms

- How to de-energize stored energy

- How isolation must confirm.

- Training Programs: Training is required for two types of employees: authorised and affected. Authorised employees maintain and service machines and are qualified to control hazardous energies. In contrast, affected employees work near the machines/equipment being serviced or repaired under lockout and must understand the hazards.

- Periodic Audits: Periodic audits ensure that energy control operations are still being done correctly, that employees are following protocols, and that they know their commitments.

What You Should Look In Lockout Padlocks & Its Benefits

Lockout Padlocks prevent mishaps by preventing equipment from being mistakenly turned on. This also prevents damage to the equipment and makes the workplace safer for everyone. Moreover, lockout Osha Lock is available in a variety of colors and is very durable, making them an excellent investment for any company.

As previously noted, are an essential component of any safety program. Workers may use Lockout Padlocks to ensure that machinery or equipment is not switched on while doing maintenance and repairs.

Safety house Lockout Padlocks may also be used to protect electrical panels, valves, and other potentially dangerous items. You may assist avoid accidents and injuries by clearly identifying dangers and shutting them out.

- Lockout padlocks are color-coded to make them easier to identify, and each Lockout Padlock may be allocated to a single employee. This guarantees that the equipment is only accessible to authorized employees.

- Padlocks, when utilized appropriately, may help make your workplace safer for everyone.

- It is a low-cost and easy approach to safeguarding the safety of your employees. Among the advantages are:

- Preventing mishaps by preventing equipment from being mistakenly turned on during maintenance.

- Disabling damaged equipment also protects it from additional harm.

- Lockout Padlocks are also useful for determining who has disabled the equipment since they are generally color-coded.

- This is significant because it makes everyone’s workplace safer.

Lockout Padlocks and Lockout Kits are a simple and efficient approach to increasing workplace safety and should be utilized wherever equipment is a danger of harm.

Conclusion

If hazardous energy is not appropriately managed workers doing regular machinery or process equipment maintenance may be badly hurt. It is why safety lockout tagout padlocks are used to turn off possible energy risks and avoid such mishaps.

To purchase the best lockout products as per OSHA standards contact the Lockout Supplier Safety House Loto.

You May Also Like: How to Ensure Worker’s Safety From Lockout Tagout Procedure?

You May Also Like: What is the Purpose of Lockout Tagout: Advantages & Disadvantages

Safety Lockout Hasp: Types, Benefits, and Its Uses

Lockout hasps are widely used for safety procedures because of their unique functionalities. Of course, it will develop a good one and be able to adapt to multi-person lockout. They ensure a good outcome and establish a new solution for choosing branded safety lockout hasp and its uses.

However, the safety lockout has permitted us to do more completely risk-free things. It works effectively and can adapt to unlocks on the padlock from the hasp.

Types of Lockout Hasp

There are lots of safety lockout hasp available. On the other hand, the lockout provides distinct solutions and carries out energy sources. They assure good one and adapt on switched on locked out with tagout. It is mentioned by focusing on loto hasp with a date and name.

They are attached to get hasps and efficiently take successful outcomes for your lockout program. It will develop colored-coded by depends on the engineer’s choice and development.

- Snap-On Hasp Style

- Standard Hasp Style

- Scissor-Action Hasp Style

- Heavy-Duty Hasp Style

- Dual-End Hasp Style

- Loto Color Hasp

- Mini Hasp Style

- Safety Hasp Style

What are the Benefits of Lockout Hasp?

It provides a clear-cut solution for lockout, and hasp should take a good choice forever. The lockout hasp should combine well and ensure a good outcome for showing possible choices.

Strong and durable plastics made

On the other hand, the safety lockout hasp should combine with individual needs. The strong and durable industrial haps can give good outcomes and restores them quickly. Moreover, it will be aligned to get the carrying maintenance forever.

The padlocks and others should combine with lockout hasp by focusing on restored options. Hasp comes forward showing more options and enjoying strong plastics depending on the requirements. The hasp lockout must develop a good one and explore maintenance properly done with a major solution.

Ensures low maintenance

Likewise, the safety lockout hasp should come with one energy source. It gives more usability and can adapt to each person to create a long-lasting solution. The lockout kit and group box with hasps adapt to focusing on high-quality collections that depend on the requirements.

Loto hasps provide a good one and explore energy to retain on the padlocks that have been removed so far. Moreover, this device ensures a clear-cut solution and adapts to low-maintenance work forever.

Changes in simple cable fit

The safety lockout hasp and its uses must develop a good one and adapts on warning. Hasp will explore a lot and is mainly applicable to notice changes in removing padlocks and others. Thus, a simple cable tie to a padlock with unique functionalities.

Moreover, it will control mainly by focusing on high-end results. It will update changes in the simple cable and fit, tampering, and others. So, Lockout India carries out more things and is mainly suitable for lockout tags for your communication needs.

Read More: What is the Purpose of Lockout Tagout: Advantages & Disadvantages

Read More: What Are The Usage Of Electrical Plug Lockouts?

Read More: How To Use Lockout (Loto) Kit?

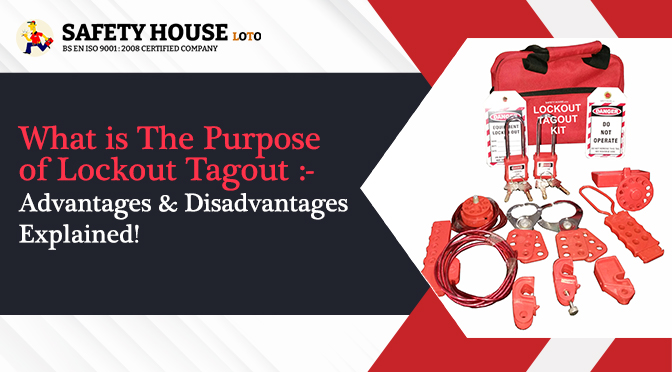

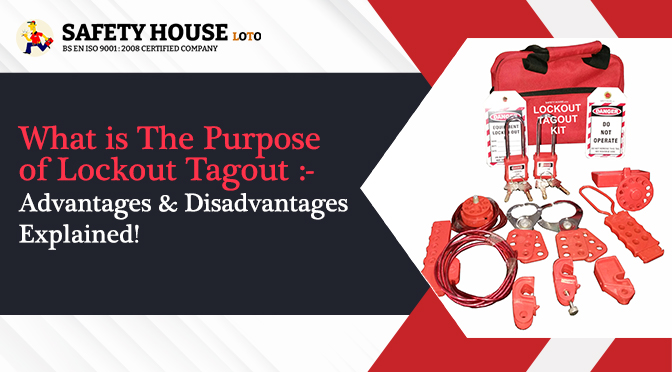

What is the Purpose of Lockout Tagout: Advantages & Disadvantages

The purpose of the Lockout Tagout programme is to increase the workplace’s safety. Working with machinery may be hazardous, but taking the necessary precautions can significantly reduce the danger.

Safeguards against being crushed or injured by moving components are examples of protective measures that may implement. They may also incorporate measures to prevent electrocution from occurring.

One of the main purpose of lockout tagout programme has become so significant in many facilities’ safety systems because it gives multiple advantages to a large number of people at the same time.

What Is Lockout Tagout (LOTO) and How Does It Work?

The purpose of LOTO (Lockout Tagout) is to ensure that equipment is switched off, rendered unusable, and de-energized before it may use again.

This makes it feasible to repair and maintain the system in a safe and secure environment. The Lockout Kit is one of the most useful safety equipment collection kits that is helpful in many dangerous situations.

Lockout/Tagout procedures must follow in any workplace where equipment may unintentionally discharge potentially hazardous energy if not properly maintained.

Advantages of Lockout Tagout Products

When a person incorrectly assumes that a machine has been properly switched off, it may be a serious incident. LOTO is a means of shutting down all computers, machinery, and equipment simultaneously to protect yourself and others.

If accidents and fatalities can prevent, it is possible to decrease production time losses while increasing overall profits. The following are some of the advantages of lockout.

- Reduces the likelihood of injury occurring if machines are accidentally triggered by a mistake.

- The risk of injury or death from hazardous energy releases such as steam blasts, corrosive chemicals, and electrical arc flashes is minimized to the lowest degree possible.

- This approach saves the lives of people.

- Reduce the possibility of legal action.

- Benefits and reductions in workers’ compensation insurance premiums are offered in several counties if a firm has fewer accidents.

- Making safety a high priority at work has the effect of creating confidence and trust in people.

- Profitability

Disadvantages of Lockout Tagout

Lockout/Tagout rules and standards have been established by the Occupational Safety and Health Administration (OSHA) to protect employees, equipment, and the workplace while performing maintenance and repairs.

Read More: Importance of OSHA Standards

Unfortunately, several cases of deaths persist after considerable guidance and inspection, including shocks and missing fingers and the end of a person. The following are examples of disadvantages of lockout that might be fatal.

- Failure to de-energize the system

- The inability to remove residues from a location.

- Repeating the same mistake over and over

- Inappropriate training

- There is a shortage of equipment-specific lockout methods.

- Keys and locks that are synchronized

Moreover, make use of the Lockout Tagout system in your organization right now. When used properly, it may be a life-saving technology. It is important to protect employees from the release of hazardous energy when maintaining machinery or equipment by following the lockout Tagout procedures.

Popular Safety House Loto Products

>> Valve Lockout

>> Lockout hasp

>> Key Box

You Might Also Like: What is a Lockout Kit And Why is it Used For?

You Might Also Like: Common Yet Useful Lockout Devices

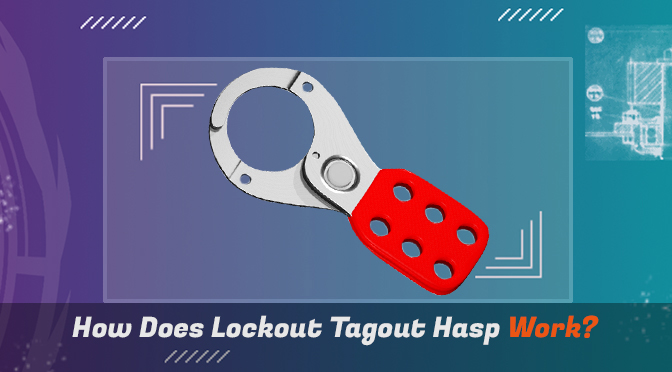

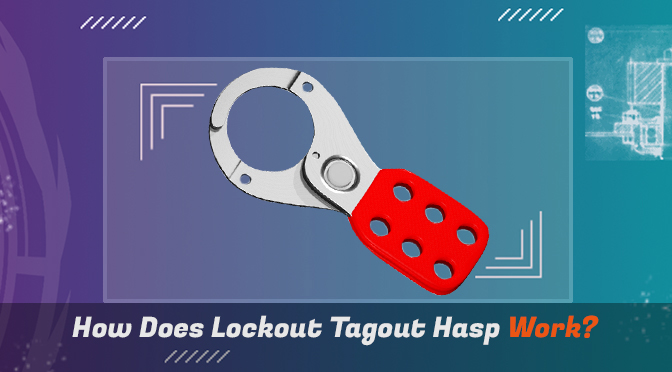

How Does Lockout Tagout Hasp Work?

The term “lockout tagout” refers to the procedures used to ensure that the machinery is shut down until the maintenance task is done. The safety lockout products are used to prevent any injury or mishap due to the machinery.

Usage Of Lockout Hasps

Lockout haps are used when two or more employees are involved in a lockout tagout operation.

Lockout Hasps are important for better safety lockout programs or procedures. These safety lockout tagout hasp provide efficient multi-person lockout.

Multiple padlocks can be applied to Loto Hasp, allowing an energy source to be isolated by more than one worker. This means that the energy source is completely locked out and can’t be operated until each worker unlocks their padlock from the loto hasp.

In the next section, we will tell you about the working of safety lockout products!

The Working of Lockout Tagout Hasp

The Lockout Hasp clips onto several different areas of a hazardous energy source, ensuring that it can’t be switched on (LOCKED OUT) and tagging it visually (TAGOUT). Manufacturer of lockout products marks the lockout hasp with a date and name and attaches a padlock to the hasp.

As a result, the hasp is efficiently used in a successful safety lockout program. The major purpose of Loto products is to increase the ease of access and safety with a clear distinction between the keys and their placement.

Types Of Lockout Tagout Hasps

There are two types of loto hasps based on their reach:

- Long Reach Hasps

- Short Reach Hasps

Now which type of hasp is better for you depending on your requirement, the number of employees involved in the task, and the kind of machinery under process?

Why Do I Need To Worry About Lockout Tagout?

Are you doubtful about the need for lockout hasp? Well! Let us tell you that without such safety equipment, your employees can be at serious risk of injury or even killed by the machinery. We hope that this seems like the most important reason to opt for efficient safety lockout products immediately.

If you’re looking to buy safety lockout tagout products, let us tell you that there are various types of hasps available in several different sizes. The variety of loto hasps available in the market allows workers to isolate any energy source required effectively. Additionally, padlocks applied to the Lockout Hasp are well-distinct with different colors; it tells which engineer has the key. This feature enhances safety.

As a leading ISO-certified company, Safety House is a one-stop solution for the best Loto products for energy isolation, workplace area safety, and site management. In addition, as an ISO-certified company, we manufacture the best quality lockout Tagout hasp. Also, customer satisfaction is our top priority.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- Osha lock

- Valve lockout

- Key Cabinets

- Universal Valve Lockout

Also read: Types of Lockout Tags & Its Usage for Industrial Safety

Also read: What is the usage of lockout cabinets or stations?

Enquire Now

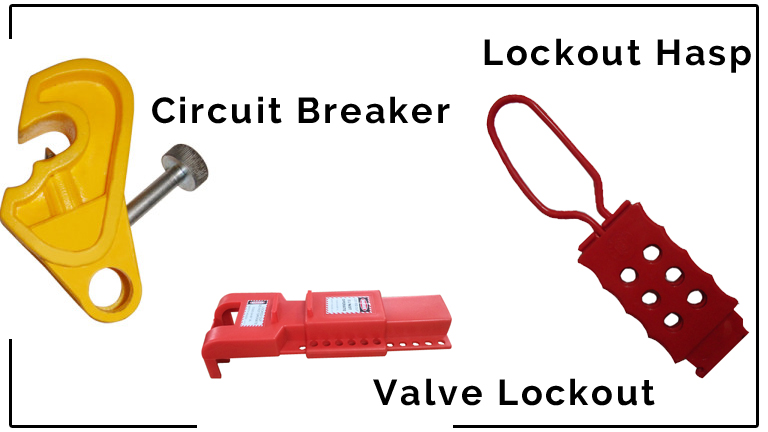

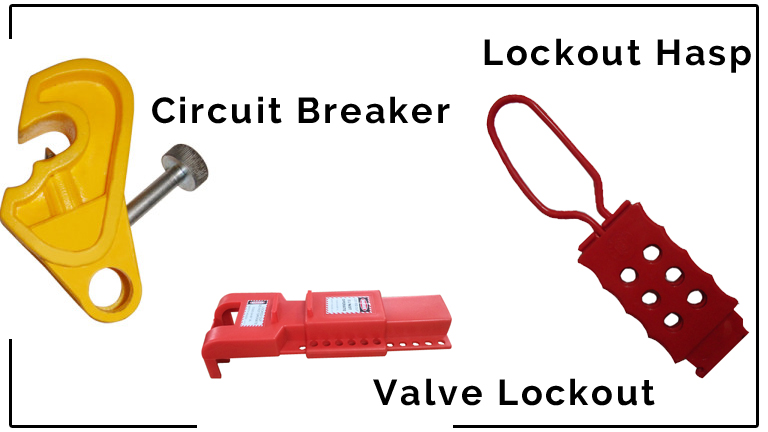

3 Common LOTO Safety Range Of Products

Hasps – At ‘Safety House – LOTO’, the best manufacturer of lockout products in India, the product range of hasps includes dielectric hasp, double jaw hasp/ dual jaw hasp and electroplated hasp. But what is a hasp? And what do they do? More than one worker often performs repair/ maintenance on a piece of equipment. Ideal for group lockout procedures, a hasp lets more than one worker to put padlock and lockout an energy source. It ensures that they remain safe. lockout supplier

Circuit Breaker Lockout – Our website ‘Lockout India’ lists an impressive range these LOTO devices that are used to isolate a particular breaker in a circuit breaker panel. Have a look at our Circuit Breaker Lockout page to see our large circuit breaker lockout, MCB lockout, MCB pin lockout, mini circuit breaker lockout and more. These lockout the breakers of all major brands. Once a breaker has been isolated, the whole breaker box doesn’t require locking out.

Valve Lockout – Valve lockouts are used for shutting off gas or fluid valves. Preventing these valves, including ball valve (Commonly used handles that are turned at 90° to shut off.), cylinder valve, butterfly valve and gate valve (These are round knobs.), from opening is important, when repair work/ maintenance is being performed. While gate valve lockouts are measured by their diameter, ball valve lockouts are determined by the handle length. You may also like to have a look at our butterfly valve lockout.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now