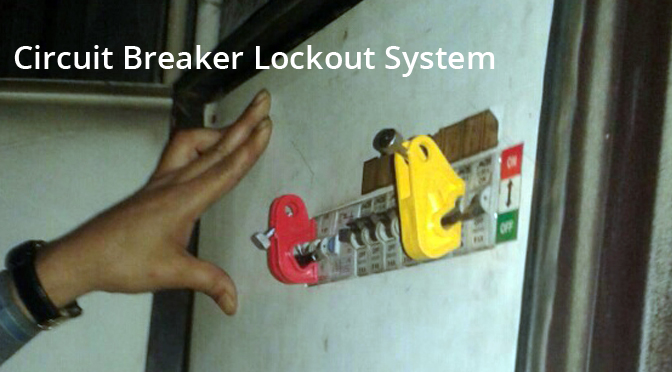

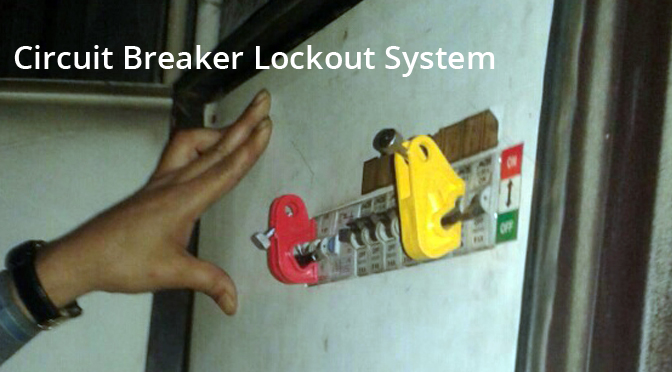

Circuit Breaker Lockout System

You must have observed MCB’s (Miniature Circuit Breaker) installed in your house. When you switch on or shut-down the appliance, the electricity of an entire floor gets affected. This is because all the circuits in the floor are connected with the MCB Lockout and by turning off the main switch, the lights go out. However, this is not the prime task of a circuit breaker but to protect the appliance and the people from potential electrical shocks and faults. In other words, Circuit Breakers are the appliances that blocks possible electrical short-circuits and helps maintain the flow of electricity.

A lot of people fail to comprehend the reason as to how Circuit Breakers come under the OSHA guidelines. As per OSHA’s standard 29 CFR 1910.147, all the devices that are dangerous and can cause accidents must be disconnected from all kinds of appliances, including Circuit Breakers so that the machines can’t operate itself in absence of workers. And since Circuit Breakers are basically like a switch with on/off system, it’s required to count them in Lockout-Tagout procedure.

Circuit breakers lockout system involves locking out the switches of the circuits through circuit breaker lockout equipment. The kit includes yellow rail assembly, 2 x 1-way pins, 1 x 2-way pins, 1 x cup pin, pin holder, and self tapping screws which come specifically designed for each panel. The process of killing the switches is very easy through the Lockout Kit.

There are numerous lockout-tagout service providers in the country. However, not all of them deliver quality products to their customers. ‘Safety House’ is a trusted company that has been in business since a considerable amount of time and has hundreds of satisfied clients. So make sure to choose the best LOTO service provider for your establishment which meets your requirements.

Checkout Our Other Lockout Tagout Products:

- Lockout hasp

- Group Lockout Box

- Lockout Station

- Valve Lockout

Enquire Now

What Is A Group Lockout Box?

Lockout-Tagout procedure as implemented by OSHA (Occupational Safety and Health Administration) is the best way of securing the workplace and making the workers feel safe and easy. Along with describing the procedure and the necessary LOTO Kit, OSHA’s guidelines highlights the companies which come under their coverage and which don’t. Out of the numerous Lockout Tagout Procedures, one such process is Group Lockout.

Group Lockout-Tagout process is a way of providing the workers a high-level of security. The procedure involves multiple employees working together to perform a service check on a device or machinery which is potentially hazardous and can cause severe damage to the workplace and the employees. The objective is to assign a worker who will overlook the entire process and will be responsible for any mishaps. Also, every worker is required to apply their own Lockout Padlocks to the isolation points on the machine in order to ensure that the device cannot be re-energized until everyone has finished their work and are at safe location. Manufacturer of Lockout Products

For diverse workers, Group Lockout Boxes are used with keys to single or multiple equipments. The keys to lockout devices disconnect master keys which are placed in the Group Lockout Box. Every worker is then required to place his or her own personal lock on the box. When the daily tasks are finished, the worker removes his personal lock. Further the person authorized to supervise the procedure has to verify whether all the personal locks are removed or not. Once the person makes sure all the workers have done their job and are out of the danger zone, he or she reactivates the machinery.

‘Safety House’ manufactures top quality Lockout Tagout Products such as Padlocks, Breaker Kit, Butterfly valves, Lockout Hasp, etc including Group Lockout Boxes which perfectly comply with your requirements.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

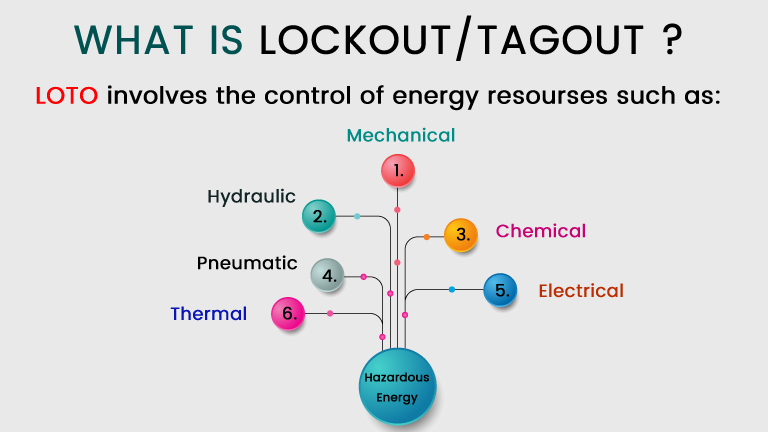

Learn About Lockout Tagout Procedure To Control Hazardous Energy

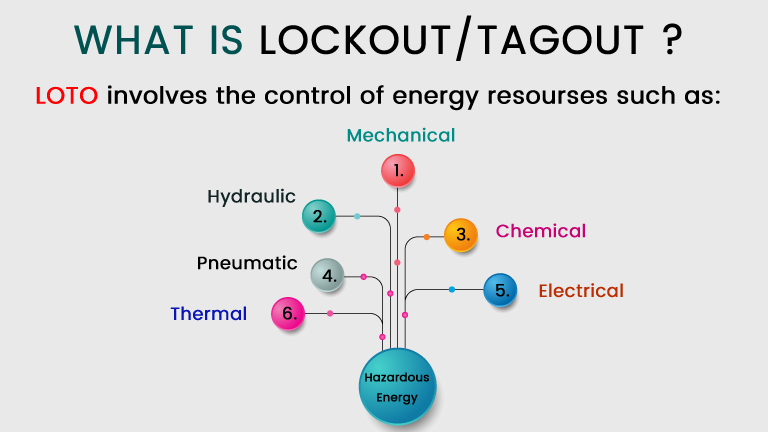

Lockout-Tagout procedure is a very safe and serious practice of safeguarding the workers from the potential threat of unanticipated release of harmful gases or other forms of energies. It is an integral part of workplace security and an OSHA standard which demands the employers to create a LOTO system for their establishment. According to some recent stats uploaded by OSHA, Lockout-Tagout process helps prevent approximately 50,000 injuries and 120 deaths

of employees per annum. It is a sentry technique of protecting the workers by making sure that no noxious devices can operate sporadically on their own via turning off and locking out the equipments appropriately.

The primary steps of Lockout-Tagout procedure are:

1. Person in-command must ponder through the entire process.

2. He or she must recognize all parts of the system that needs to be turned off.

3. Should select wisely as to what switches, devices and people will be involved in the procedure.

4. Must formulate the plan cautiously as to how the device will be restarted.

Furthermore, the person in-charge must properly communicate with the team. Improper communication can lead to misunderstandings regarding specific tasks to execute in the process. Also, the workforce not involved in Lockout safety procedure must be alerted about it. All kinds of recognizable electrical circuits, hydraulic and gravity systems, etc must be disconnected from the power source. The movable parts must be blocked and the dangling parts must be put to resting positions.

Once the process has been carried out, double checks must be performed to ensure that no loose ends were left. And when it’s the time to reenergize the equipment, proper inspection must be done to make sure that the machine is kept intact as it was left out and all the unnecessary items lying around should be removed.

Lockout-Tagout Products has considerable benefits and it is suggested that one must follow the program and provide essential training to his or her employees.

Checkout Our Other Lockout Tagout Products:

- Lockout Hasp

- Group Lockout Box

- Lockout Station

- Valve Lockout

Enquire Now

Why Valve Lockout Devices Are A Necessary Workplace Requirement

The safety and security of the workforce is important for any organization and it is their duty to ensure that the employees work in a hazard fee environment. The unexpected energization or startup of machines can pose some serious threat to the workers. Lockout Tagout Products provides protection that hold energy isolation devices in a safe position and prevents the release of hazardous energy and prevents machines or equipments from getting energized. In case machinery that the company employee is servicing or maintaining unexpectedly energizes, starts up, or releases stored energy then it can have very fatal consequences and injure the worker concerned.

Valve Lockout Devices For Workplace

Similarly valve lockouts prevent the occurrence of any harmful accidents during maintenance or repairs. With the help of Valve lockout devices workers can close off or isolate energy sources such as electricity and hydraulic pressure. By the statistical data compiled by OSHA (Occupational Safety and Health Administration) three million workers that majorly include electricians, machine operators, and laborers face this risk at work places. A victim can fracture their arms or legs, get burnt or electrocuted in the light of such an accident occurring. This is a serious issue on a personal level as the life and physical health of a laborer is concerned and also staff getting injured would gravely affect the productivity of an establishment.

Valve Lockout device is easy to use, safe and an inexpensive way to secure valves and prevent injury. They are used at workplaces to close off different kinds of pressured valves, these devices ensure that machineries that are value operated do not accidentally start working and remain switched during any maintenance work. The Valve Lockout Devices are attached over the operational part of the valve.

Safety House, the best manufacturer of lockout products In Delhi emphasis on taking prevention measures rather than waiting for accidents to happen. We also manufacture a wide range of the best Valve lock out Device.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Loto Kit

Enquire Now

Control Heavy Electricity Flow at Your Workplace

Lockout and Tagout have been widely used by almost every small and large companies across the world to insure safety of their employees or workplace. A large range of LOTO products for preventing any kind of accident at work place and Circuit Breaker Lockout is one of them. Circuit Breaker system are specially designed to protect electrical circuits from damage caused by overload or short circuit. Control Heavy Electricity Flow

To detect the fault condition and open the circuit automatically when there is a fault is the basic function function of a circuit breaker. It is usually used as a manual energy- isolation device by manually placing it in the OFF position. Circuit Breaker system can be of any size and shape. So we will tell you about different types of Circuit Breaker Systems.

1. Types of Circuit Breaker Lockouts

2. Pin Type Circuit Breaker lockout

3. Miniature Circuit Breaker Lockout

4. Large Circuit Breaker Lockout

5. Universal Circuit Breaker Lockout

6. Circuit Breaker Lockout Kits

7. 480-600 V Breaker Lockout

8. Wall Switch Lockout

The Circuit Breaker Lockout has been designed to lockout little circuit breakers and therefore prevent accidental switch on. These devices works with all Lockout Safety padlocks and most hasps.

Instructions For Use

1. Switch “OFF” the circuit breaker handle

2. Place the lockout over the handle

3. Tighten the set screw by hand, rotate the toggle

4. Apply a lockout padlock

5. Make sure the switch is completely locked out and cannot be energized until the lockout device is removed.

Lockout India is a manufacturer of lockout products. They manufacture Lockout Tagout Products under OSHA standard.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Know More About Lockout Devices & Their Necessary Criteria

Many industrial accidents happen due to unexpected energisation of machines at workplace. To prevent such accidents from happening and to ensure a safe work environment for the employees, it is important for the organization to implement lockout devices. We at Safety House, the best manufacturer of Lockout Tagout Products in Delhi believe in being well prepared and fostering a culture of safety. There are certain criteria’s that Lockout Tagout Devices must meet before being used by any organization:

a) Lockout devices must be compatible with the work environment they are being used in. Tagout device warnings must remain legible even when they are used in wet, damp, or corrosive conditions.

b) Lockout and tagout devices must be designated by color, shape, or size and must have a standardized print and warning format.

c) The lockout and tagout devices must be really strong so that they can’t be removed inadvertently.

d) Tagout devices must be attached with a single-use, self-locking material such as a nylon cable tie.

e) Whichever employee sees the lockout or tagout device must be able to recognize who attached it and its purpose.

f) Each lock must have a unique key or a combination.

Safety House manufactures the best quality LOTO Products such as cylinder lockout, cable lockout and many more that meet the above necessary requirements.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now