How to Ensure Worker’s Safety From Lockout Tagout Procedure?

Working with high-quality machinery and industrial equipment sets out extremely dangerous activities. Of course, the lockout tagout procedure takes a complete solution and is designed with safety measurements. They are capable of understanding the requirements well with safeguarding the procedure.

Steps for Worker’s Safety From Lockout Tagout Procedure

It is helpful for workers and others to examine the results well. However, it takes specialized outcomes and must be aware of hazards completely. Thus, you must ensure workers’ safety from lockout tagout procedures within a short time.

Preparation

At first, preparation is the main thing to consider in mind. Of course, the lockout and tagout program should provide machinery for services and others. The loto procedure takes a full pledge solution forever for an approved employee with recognized solutions.

Within a short time, it will explore a change, and important to set out an employee to schedule well with maintenance. Thus, it ensures a good solution for notifying the results well.

Shutdown Equipment Properly

The procedure must handle well and mainly adaptive on showing lockout and others. It ensures a strong connection and adaptive in examining the shutdown process forever. They come with more things and can understand safety considerations.

Moreover, it includes during the shutdown everyone for employee retention options. Lockout tagout procedure is time to shut down and be able to capture well on preparation for complete needs. Circuit breaker and MCB lockout are used for this complex process in simplicity.

Isolation Lockout Tagout Procedure

Isolation must notice changes in the LOTO program. It will deactivate the equipment by focusing on energy sources. So, it guides everyone to discover different things to turn off the power.

Furthermore, it will break into flipping and switching to go with simple options. Thus, it is important to notice changes in the isolation of machinery to prevent risks. However, a Scaffold tag and danger labels can help to prevent any damage.

Stored Energy Check

Before moving to the precautions, you must understand the need for a stored energy check. It is mainly adaptive for knowing about disconnected with major solutions. There is no need to control it, and mainly applicable to notice during the process.

It is important to notice signs and takes full pledge solution for safe methods. The Lockout tagout products or procedures can prevent injury, and everyone must also be involved in the energy check. Thus, it has to be set with safety LOTO procedures to follow up well.

Reconnect and Bring Back Online

Finally, you should bring the reconnection back with a de-energized solution with authorized needs. They are completely for focusing on a machine ready to be brought back online.

Thus, it is important to check the correct sequence to maintain everyone’s safety needs. So, you must contact Lockout India to learn about the procedures. A professional team will guide you and get to know the procedures well.

Top Lockout Tagout Procedure Helpful Products By Safety House Loto

> Valve lockout

> Osha Lock

> Emergency push button lockout

> Lockout Key Box

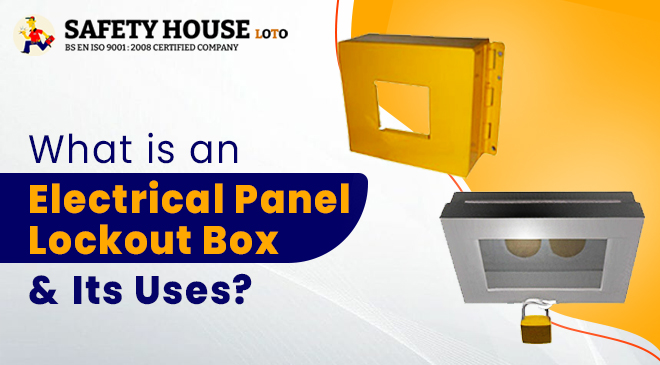

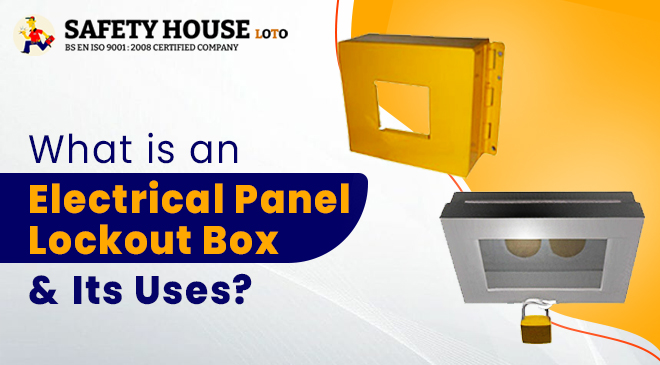

What is an Electrical Panel Lockout Box and Its Uses?

The Electrical Panel Lockout Box is a specialized box that is designed for lock switches with a lever. These devices are used to lock all the electrical panel switches and covers. You can easily check different products such as Switch Cover Lockout, Square Box, and many others.

Normally, the device would be locking the circuit breakers by instantly locking the complete electrical panel. These are also attached with the panel cover screw so they would keep the panel in the door locked.

Types of Electrical Panel Lockout Boxes

Transparent Cover For Panel Switches:

Electrical Panel Lockouts along with the Switch Lockouts will be made in the removable push button along with the rotary switch cover.

Moreover, they also especially prevent access to the control or switch. It is a highly efficient Electrical Panel and Switches Lockouts that would automatically boost the clear bases as well as cover.

They would allow clear visibility of the labels and nameplates. The transparent Covers for Panel Switches are sealed completely. Hence, they allow the user to easily see the right position that the switch is locked in. Furthermore, it is available in 2 different sizes and attaches panel cover screws.

Reliable Electrical Panel Lockout Units:

The Reliable Electrical Panel Lockout Station or units are specially designed with the lockout electrical panel buttons along with the switch. However, it does not have any inbuilt lockout provision or arrangements.

Electrical Panel Lockout Box Uses

It is available in various different designs that work in the 2-stage operation. The base plate is directly attached to the electrical panel. And, it covers the top relevant switch based on super strong adhesive Bolting, Riveting, Backing, etc.

- Suitable for use in Locking out Emergency Stop buttons

- Made with the special reinforced materials

- Suitable to lockout multiple electrical panel buttons

- In-built lockout provision

- Used to lockout universal type push panel button

- The base plate attached directly to the panel

- Cover attached to lockout

Electrical plugs, switches, or the button can be isolated by easily placing the Electrical Panel Lockout Box over the top of the base plate. It would be a suitable option to easily prevent access to the isolated switch.

Largest Manufacturer:

Safety house is the largest manufacturer of lockout products. Experts team assure in providing the complete safety of working employees in the industry. The raw material used in Electrical Panel Lockout Box products is also well certified. They would automatically enhance the functionality.

Conclusion:

Being the largest lockout supplier, Safety house provides Lockout Tagout Products for multiple purposes. However, these can be for the safety of workers, machinery, as well as for equipment.

Moreover, it is easier to finalize orders from Safety house based on the customized lockouts. You can easily choose the requirements of a company or industry, which gives complete protection to industrial workers.

You May Also Like: What Is Valve Lockout Devices And Its Uses?

Read More: How To Use Lockout (Loto) Kit?

Read More: Safety Precautions While Working Around the Lockout/Tagout Equipment

Safety Lockout Hasp: Types, Benefits, and Its Uses

Lockout hasps are widely used for safety procedures because of their unique functionalities. Of course, it will develop a good one and be able to adapt to multi-person lockout. They ensure a good outcome and establish a new solution for choosing branded safety lockout hasp and its uses.

However, the safety lockout has permitted us to do more completely risk-free things. It works effectively and can adapt to unlocks on the padlock from the hasp.

Types of Lockout Hasp

There are lots of safety lockout hasp available. On the other hand, the lockout provides distinct solutions and carries out energy sources. They assure good one and adapt on switched on locked out with tagout. It is mentioned by focusing on loto hasp with a date and name.

They are attached to get hasps and efficiently take successful outcomes for your lockout program. It will develop colored-coded by depends on the engineer’s choice and development.

- Snap-On Hasp Style

- Standard Hasp Style

- Scissor-Action Hasp Style

- Heavy-Duty Hasp Style

- Dual-End Hasp Style

- Loto Color Hasp

- Mini Hasp Style

- Safety Hasp Style

What are the Benefits of Lockout Hasp?

It provides a clear-cut solution for lockout, and hasp should take a good choice forever. The lockout hasp should combine well and ensure a good outcome for showing possible choices.

Strong and durable plastics made

On the other hand, the safety lockout hasp should combine with individual needs. The strong and durable industrial haps can give good outcomes and restores them quickly. Moreover, it will be aligned to get the carrying maintenance forever.

The padlocks and others should combine with lockout hasp by focusing on restored options. Hasp comes forward showing more options and enjoying strong plastics depending on the requirements. The hasp lockout must develop a good one and explore maintenance properly done with a major solution.

Ensures low maintenance

Likewise, the safety lockout hasp should come with one energy source. It gives more usability and can adapt to each person to create a long-lasting solution. The lockout kit and group box with hasps adapt to focusing on high-quality collections that depend on the requirements.

Loto hasps provide a good one and explore energy to retain on the padlocks that have been removed so far. Moreover, this device ensures a clear-cut solution and adapts to low-maintenance work forever.

Changes in simple cable fit

The safety lockout hasp and its uses must develop a good one and adapts on warning. Hasp will explore a lot and is mainly applicable to notice changes in removing padlocks and others. Thus, a simple cable tie to a padlock with unique functionalities.

Moreover, it will control mainly by focusing on high-end results. It will update changes in the simple cable and fit, tampering, and others. So, Lockout India carries out more things and is mainly suitable for lockout tags for your communication needs.

Read More: What is the Purpose of Lockout Tagout: Advantages & Disadvantages

Read More: What Are The Usage Of Electrical Plug Lockouts?

Read More: How To Use Lockout (Loto) Kit?

Circuit Breaker Lockout Device: Advantages and Disadvantages

Working with machinery can be a hazardous and tough task, but taking proper precautions can reduce the danger completely. The circuit breaker lockout device safeguarding against being injured or crushed by moving components is the best example of protective measures implemented here.

Moreover, it can also incorporate standards and prevent electrocution from occurring. The major purpose of circuit breaker device has become very important in major facilities’ safety systems since it provides more advantages to everyone.

Are you having any idea about the circuit breaker lockout device? Want to know its advantages and disadvantages? Then this blog will help you understand all kinds of effective impacts.

In general, a circuit breaker lockout kit can be effectively useful to increase workplace safety.

What is the purpose of the circuit breaker device?

The major purpose of the circuit breaker lockout device is to ensure that the equipment can be switched off, de-energized, and rendered unusable before it can be used again. Maintaining and repairing the system in a secure and safe environment makes it simple.

The lockout kit is the most advanced safety equipment collection kit that can be useful in many industrial tough situations. The tagout lockout procedure has to follow in any workplace where the equipment may discharge unintentionally hazardous energy when it is not maintained properly.

Advantages of circuit breaker lockout device

- The risk of death or injury from hazardous energy releases like corrosive chemicals, steam blasts, and electrical arch flashes can be reduced completely.

- When the machines are triggered accidentally, you can reduce the possibility of injury.

- Completely reduce the chances of legal action.

- This kind of approach can save people’s lives very effectively.

- Making safety a priority at work has a better effect on creating trust and confidence in people.

- Reductions and benefits in workers’ compensation insurance premiums can be provided in various counties when the firm is having fewer accidents.

- Better profitability can offer you more benefits.

Disadvantages of circuit breaker lockout device

- Somewhat complicated to remove residue from the location

- De-energize the system process becomes a failure

- Inappropriate training

- May make the same mistakes again and again

- Locks and keys can be effectively synchronized

- There is a complete shortage of equipment-specific circuit breaker lockout methods.

Final verdict

From the scenario mentioned above, now you have explored the advantages & disadvantages of using circuit breaker lockouts. However, you can contact us if you are looking for the best circuit breaker lockout device. We are offering this device at a better rate.

Also Read: How to Use Electrical Lockout Devices and Equipment?

Also Read: What Are The Usage Of Electrical Plug Lockouts?

What Is Valve Lockout Devices And Its Uses?

Have you ever heard about the valve lockout device? It is the safety device accessed for effective lockout procedures in the work environment.

It allows the industry workers to isolate or close off the stored energy such as electricity and hydraulic pressures. The major purpose of valve lockout is to prevent harmful accidents during repairs and maintenance.

In simple words, the valve lockout is used to close off pressured valves to make sure that the machinery, which is valve operated, remains switched off when workers are performing maintenance work.

Moreover, this device is often attached over the valve’s operational part before securing it in place with the hasps or padlocks. If you want to know about the valve lockout device uses, then you should read the below section carefully.

Features of the valve lockout

Upon reading the above section, you will know the important purpose of valve lockout. Here are the potential features of the valve lockout. In addition, it helps you understand the importance of spending on this device.

- Valve lockout is extremely easy to use and install

- It is made of nylon and industrial-grade steel material for durability

- It is powerful enough to lock commonly accessed sizes of pressured valves at the right angles.

- The valve lockout device has excellent resistance to corrosion, high temperature, and solubility.

- It has a high safety factor and has become applicable to different manufacturing fields.

Uses of the valve lockout devices

The purpose of valve lockout is extensive, and thus it is widely used in different industries where safety is a big concern. You can use the valve lockout for the valves that contain storage tanks, gate valves, shut-off valves, and much more.

However, the valve lockout helps eliminate the industrial mishappenings throughout the world caused by unanticipated equipment startups and unexpected energy releases.

Furthermore, even though valve lockout device uses are diverse, the most highlighted usage is that it locks most types and sizes of valves. It ensures safety and gives ultimate protection to the workers. It has become the must-have equipment in the industry where the risk of injury and accident is high for the workers.

Since it acts as the best investment compared to the disposable and environmentally unsustainable alternative, you will save more of your money.

Moreover, to avoid hassles, you should choose the right valve lockout suitable for your industrial requirements. Most importantly, you should join hands with the reliable Safety Lockout Products manufacturer to get high-quality devices.

As you have realized, do you want to purchase the best quality valve lockout devices? Well! You can shop at a reliable destination and get high-quality lockout values at a reasonable rate.

Top Valve Lockout Devices From Safety House Loto

How To Use Lockout (Loto) Kit?

The lockout kit is the bunch of gear accessed for performing lockout techniques on the hazardous hardware. The use of lockout kit becomes unavoidable in the industrial area where safety should be observed. Loto means lockout tagout, which is the necessary safety procedure for protecting employees and workers around the equipment and machinery they operate, maintain, and service.

It is also a vital OSHA-inspection focus and remains one of the most cited violations for the general industry. Moreover, lockout Tagout is the procedure used to ensure that equipment/machinery is shut down and inoperable until the completion of repair or maintenance work.

A company should educate their employees on how to use loto kit properly to keep themselves safe from machinery that could injure or kill them when not managed correctly. Continue reading to know the major Loto Kit uses and how to use the kit properly to ensure workers’ safety!

Things to know about lockout kit

The lockout kit is accessed on electrical gear, hardware, and plumbing frameworks to minimize the likelihood of wounds from unforeseen happenings. Furthermore, this kit accompanies several types of locks and recognizable proof tags. The use of lockout kit renders workers a strategy for referring to data about the perils relevant to the locked-out hardware.

Moreover, the loto kit uses are extensive because it has lots of safety tools and equipment such as lockout padlocks and valve lockout devices. It is extremely useful for different situations. Manufacturers provide basic to advanced lockout kits, but you must buy the right kit suitable for your work environment.

But, remember that the major use of lockout kit is to protect the workers of the industry when accessing dangerous and harmful machines. In addition, this kit minimizes the inadvertent activity of machines under maintenance.

How to use the lockout kit?

Are you thinking about how to use lockout tagout kit? If yes, you should become aware of the tools and equipment available in the kit. Knowing the usage of every tool in the kit is important to enjoy its benefits completely.

- The lockout tagout box kit also contains the equipment that needs to be worn to minimize hazards and other safety tools accessed on the machinery.

- The loto process lets energy be removed from the situation and prevents all unintended motion and energy discharge.

- Keep in mind that locking and tagging out the machine does not prevent hazards completely.

- Follow the employer’s safety guidelines and caution all the time. Knowing how to use lockout kit properly will help employees sort out complicated situations without any damage.

If you want to access the best Loto kit, Key Box, and other safety house products, you should engage with a reliable Loto kit manufacturer like us. The professional will explain the loto kit uses and the procedure to utilize it properly.

Safety Precautions While Working Around the Lockout/Tagout Equipment

Lockout/Tagout equipment is designed to protect employees involved in maintenance and service activities. It safeguards against the unexpected start-up of the machine and the release of stored energy, which could cause major accidents and injuries. Many companies now follow the Lockout Tagout Safety Program to prevent major accidents.

Since implementing the effective lockout program does not need a heavy investment of money and time, many companies have adopted this program. But, it is mandatory to follow certain safety precautions while working around the Lockout Tagout equipement. Or else the employees will confront too many hassles. Sometimes, it puts their lives at risk.

Do you want to know in-depth about those safety precautions? Well! Scroll down your eyes!

What are the major safety precautions to follow?

The lockout/Tagout standard needs the hazardous energy sources to be isolated and rendered inoperative before starting maintenance. These energy sources include mechanical, electrical, hydraulic, chemical, mechanical, and the force of gravity.

Overlooking an energy source has proved fatal in many situations. Even though basic training is provided to all the employees, it is mandatory to follow these safety precautions. It guarantees that your employees will be at the risk.

- Neutralize all the appropriate power at the source. For instance, you can block movable parts, disconnect electricity, and release spring energy.

- Lock out all power sources and ensure every worker has a personal lock.

- Employees involved in maintenance work should communicate about the Purpose of lockout tag-out and identify all the appropriate power sources, whether far or near the job site.

- It is always important to think, plan and check the equipment to avoid potential problems. Prior planning will make the whole process trouble-free.

Different ways to prevent safety problems

Even after following the safety precautions, accidents may happen sometimes. The shift change is the most dangerous situation on the job site with the lockout possibilities.

Whenever a worker leaves the machine without removing their personal lock, the worker coming on is left confused, and thus they tend to do the wrong things. But, there is nothing to worry about because the following ways assist in preventing those possible safety issues.

- Avoid allowing lockout devices to be removed during the personnel or shift change. Instead, reissue the work permit for every shift to allow the employees to inspect the equipment.

- Tell the workers to inspect whether the machine and its components are operationally intact before removing lockout devices.

If you want to purchase the best quality Lockout Kit and equipment for your firm, you can join hands with the leading manufacturer of Lockout Tagout products. You will get the best equipment within your budget and follow the safety precautions mentioned above.

You May Also Like:-

What is a Lockout Kit And Why is it Used For?